Lifting device for additive manufacturing and operational method thereof

a lifting device and additive manufacturing technology, applied in the direction of additive manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of inconvenient subsequent assembly, disassembly, maintenance, and high energy consumption, so as to reduce the processing space and the powder feeding space, reduce the loss of powders, and reduce the printing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

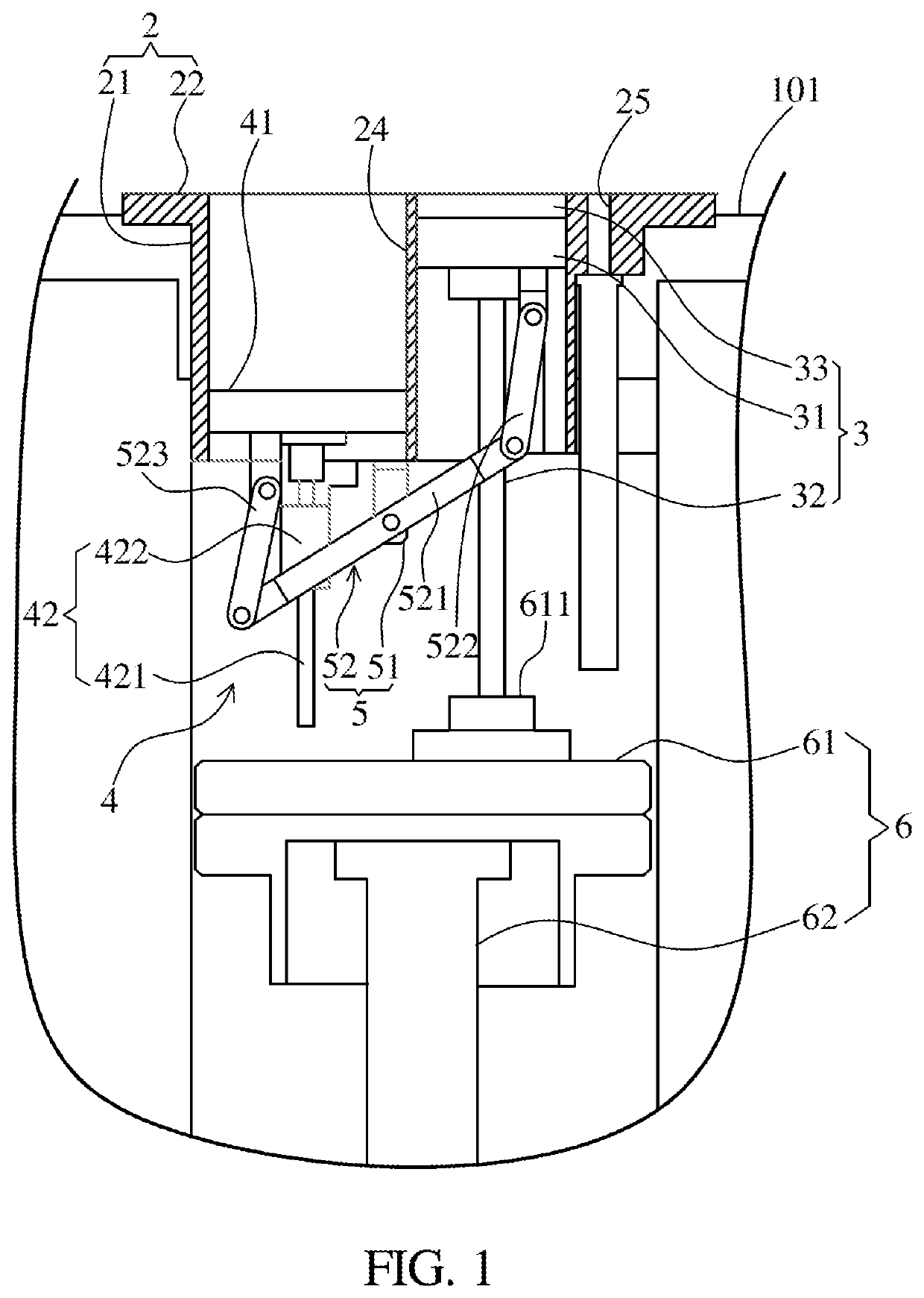

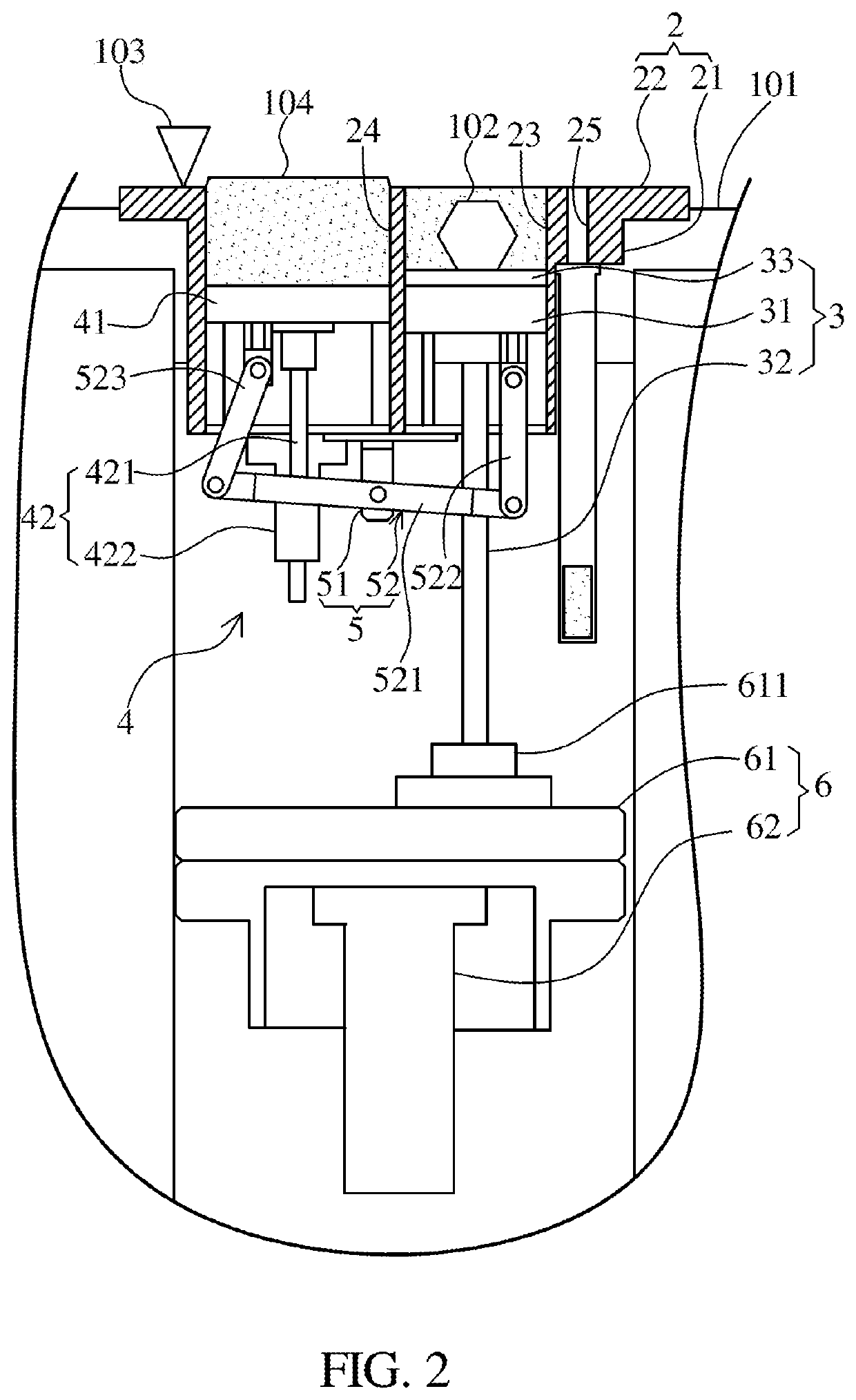

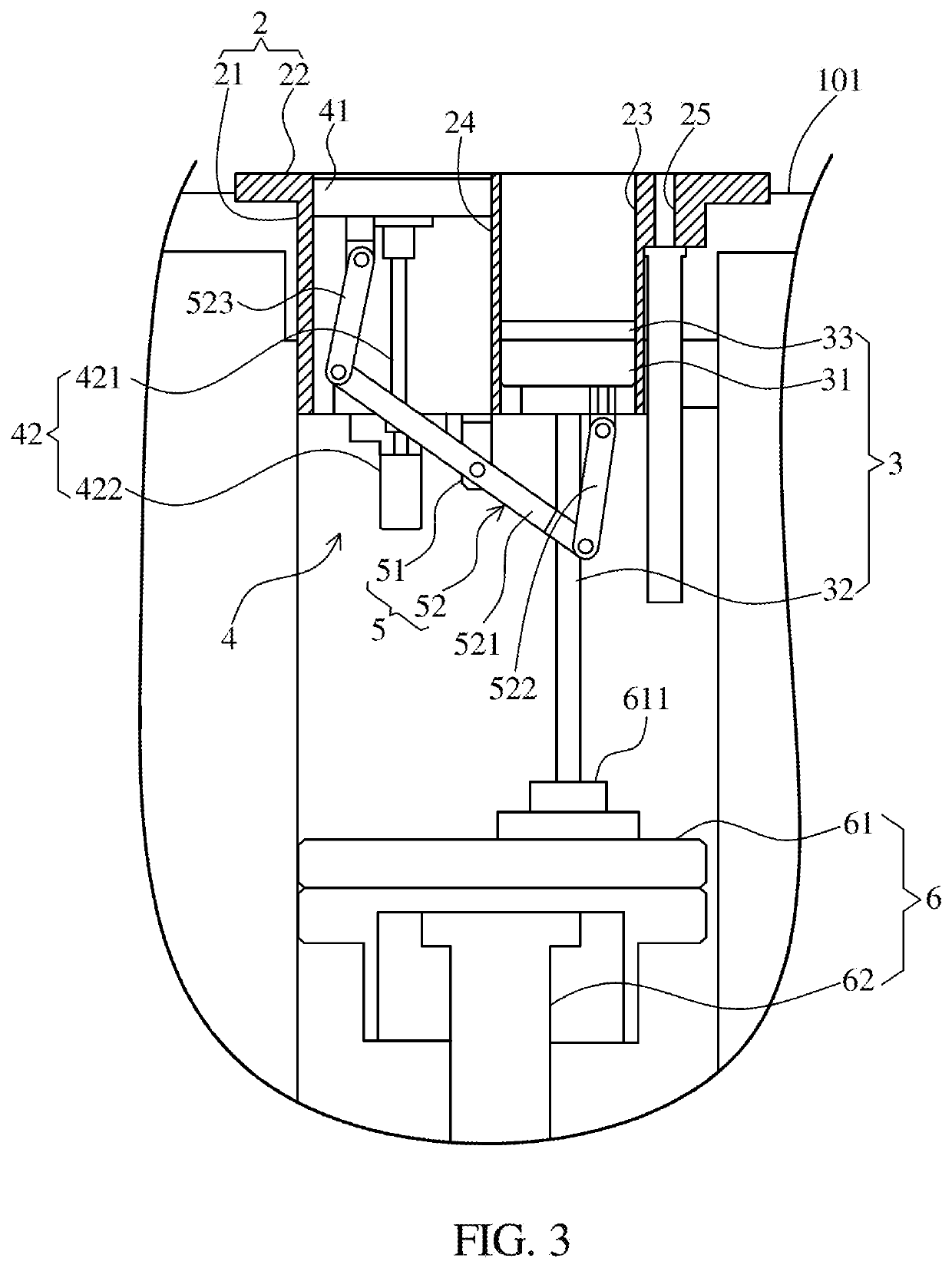

[0022]The structure and the technical means adopted by the present disclosure to achieve the above and other objects can be best understood by referring to the following detailed description of the preferred embodiments and the accompanying drawings. Furthermore, directional terms described by the present disclosure, such as upper, lower, front, back, left, right, inner, outer, side, longitudinal / vertical, transverse / horizontal, etc., are only directions by referring to the accompanying drawings, and thus the used directional terms are used to describe and understand the present disclosure, but the present disclosure is not limited thereto.

[0023]Referring to FIGS. 1 and 2, a lifting device for additive manufacturing according to the preferred embodiment of the present disclosure is illustrated, wherein the lifting device is disposed in a processing chamber 101 of a three-dimensional printing equipment for additive manufacturing and comprises a base 2, a processing module 3, a powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com