Joint connector and busbar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

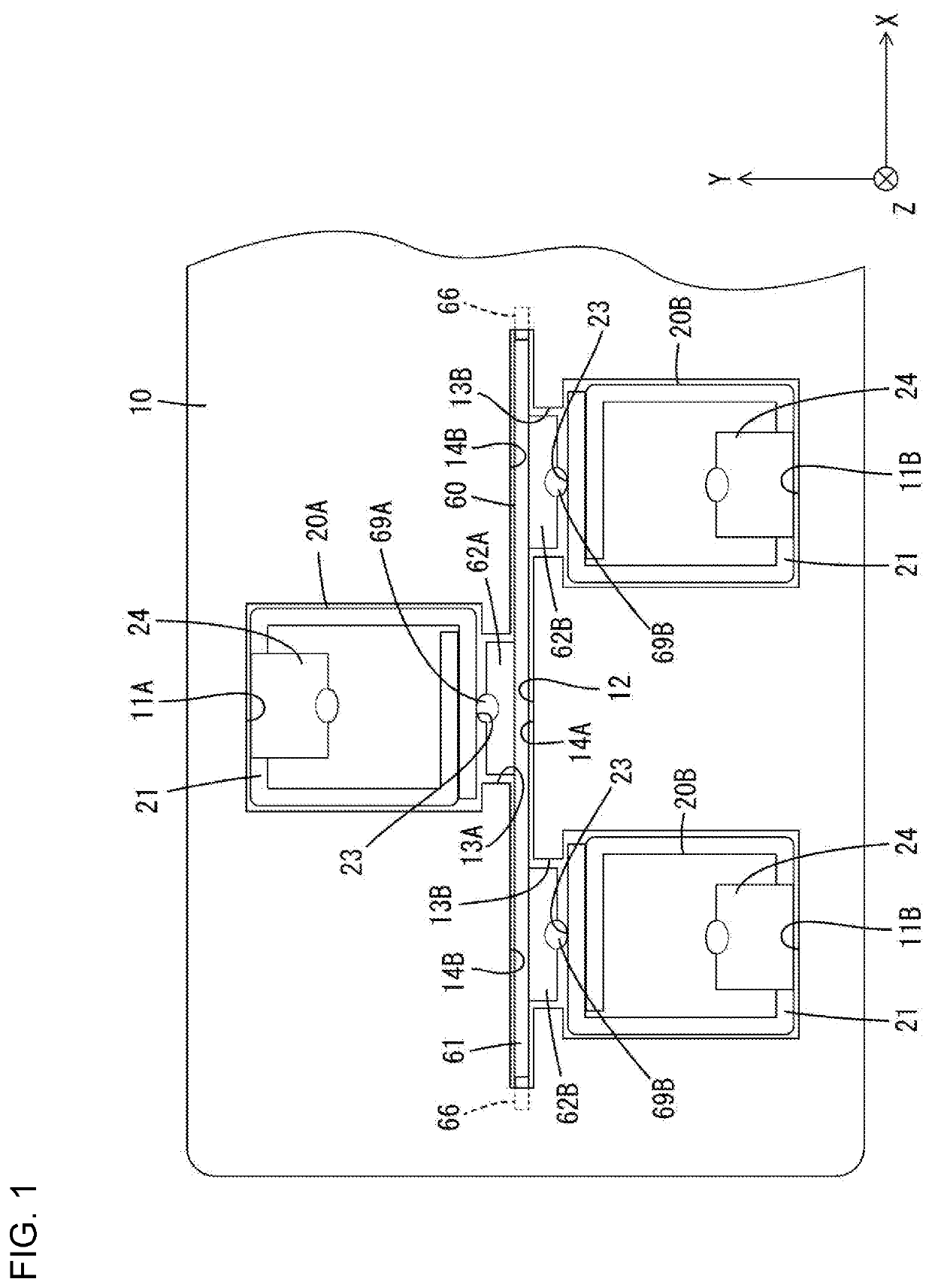

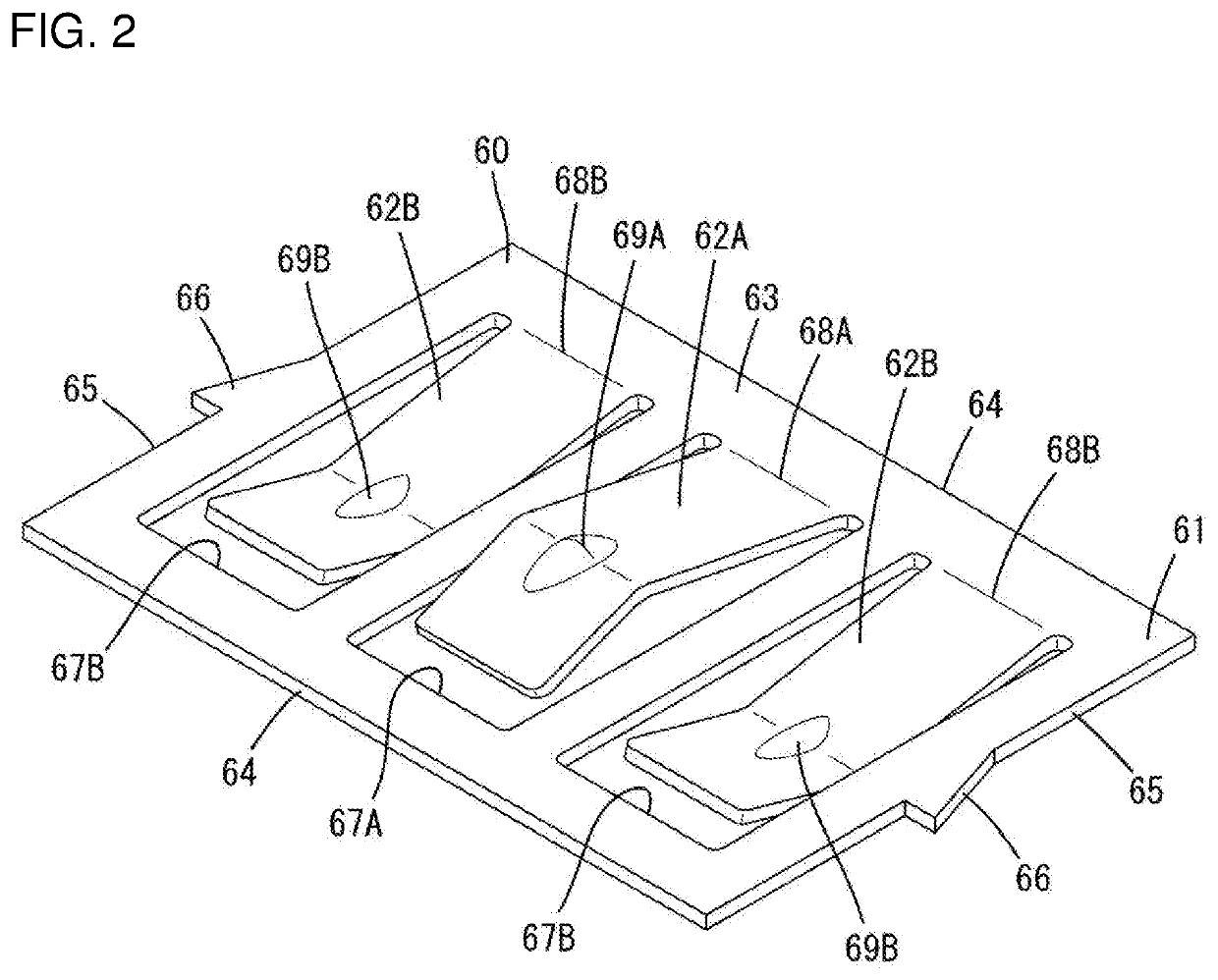

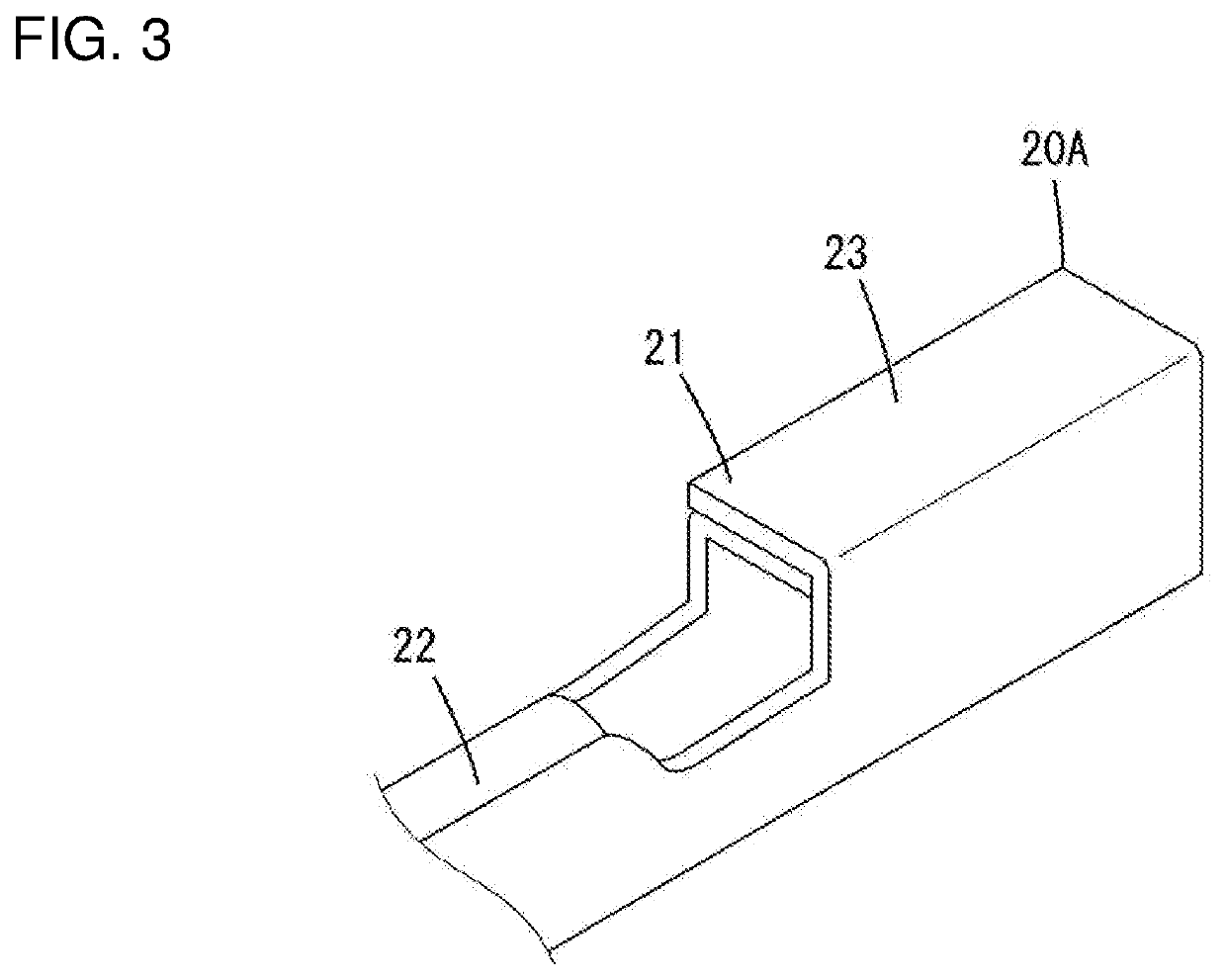

[0014]One embodiment of the invention is described with reference to FIGS. 1 to 3. As shown in FIG. 1, a joint connector of this embodiment includes a housing 10, a first terminal 20A and second terminals 20B accommodated in the housing 10 and a busbar 60 likewise accommodated in the housing 10 for short-circuiting the first terminal 20A and the second terminals 20B. The housing 10 is fittable to an unillustrated mating housing. Unillustrated mating first terminal and mating second terminals are accommodated in this mating housing. When the housing 10 is fit to the mating housing, the first terminal 20A is connected to the mating first terminal, the second terminals 20B are connected to the mating second terminals and these terminals are joined via the busbar 60. The busbar 60 is accommodated into the housing 10 accommodating the first terminal 20A and the second terminals 20B instead of in a dedicated relay housing. Thus, the configuration is simplified.

[0015][Housing 10]

[0016]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com