Lid for a container for smokeless tobacco products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

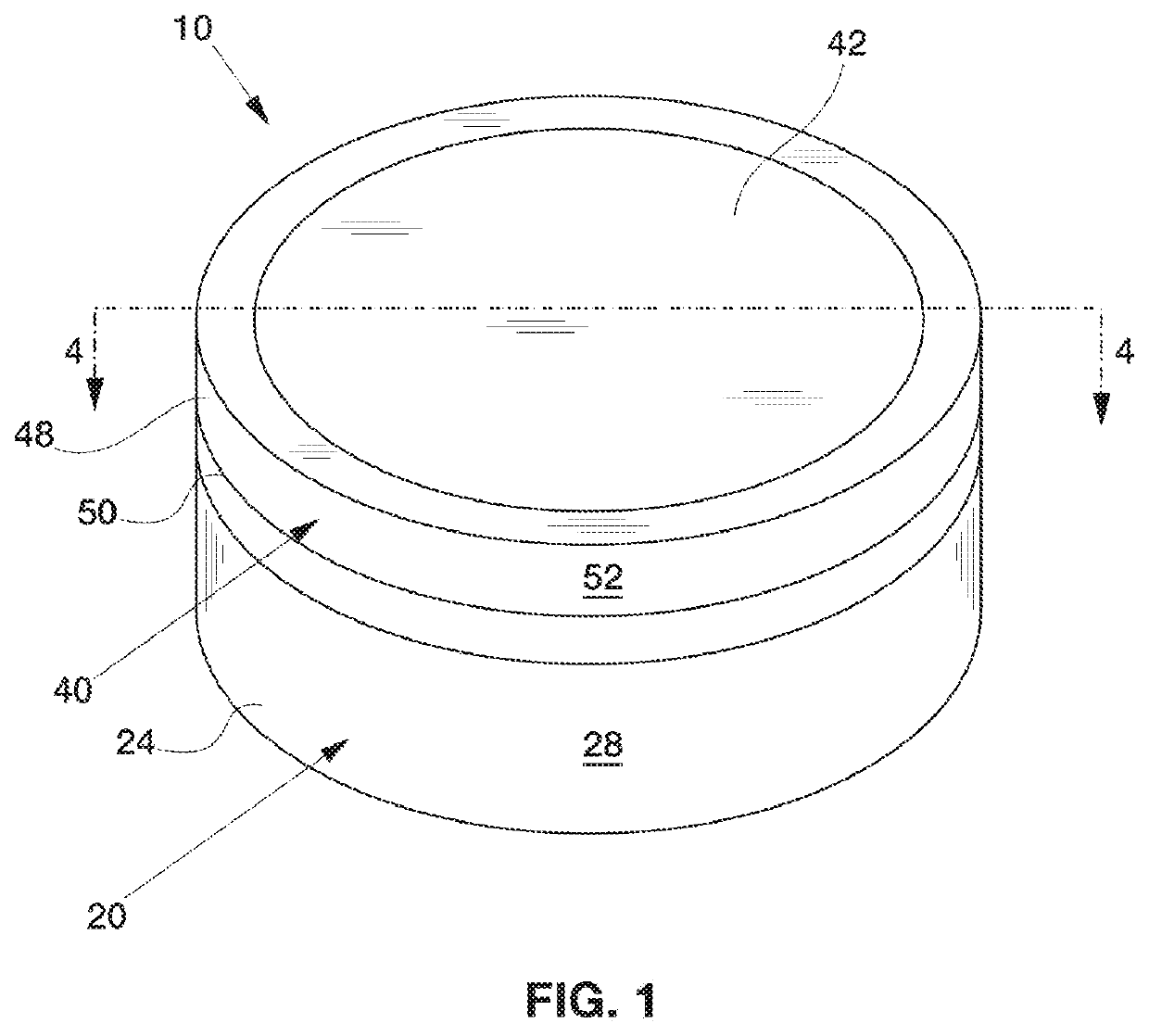

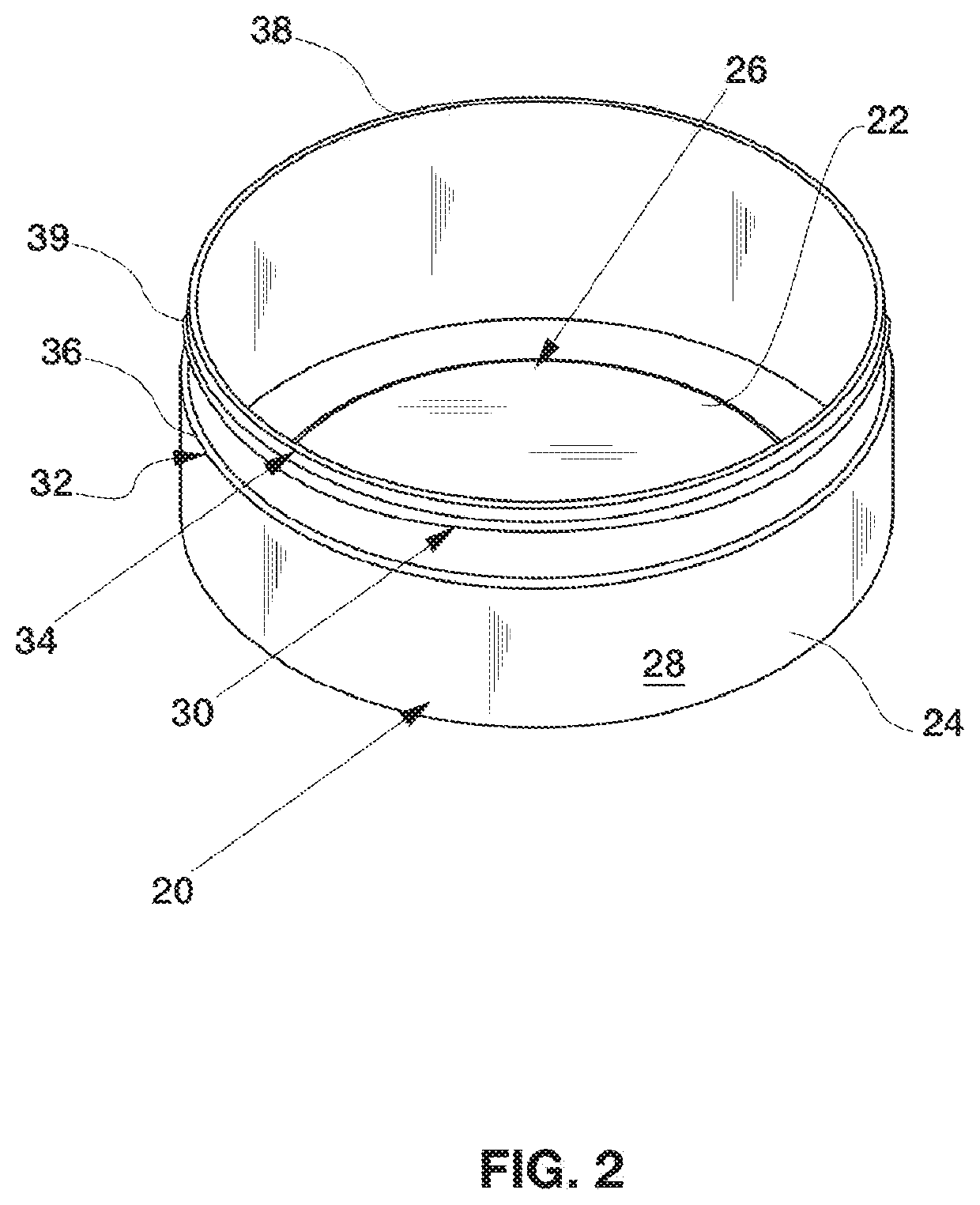

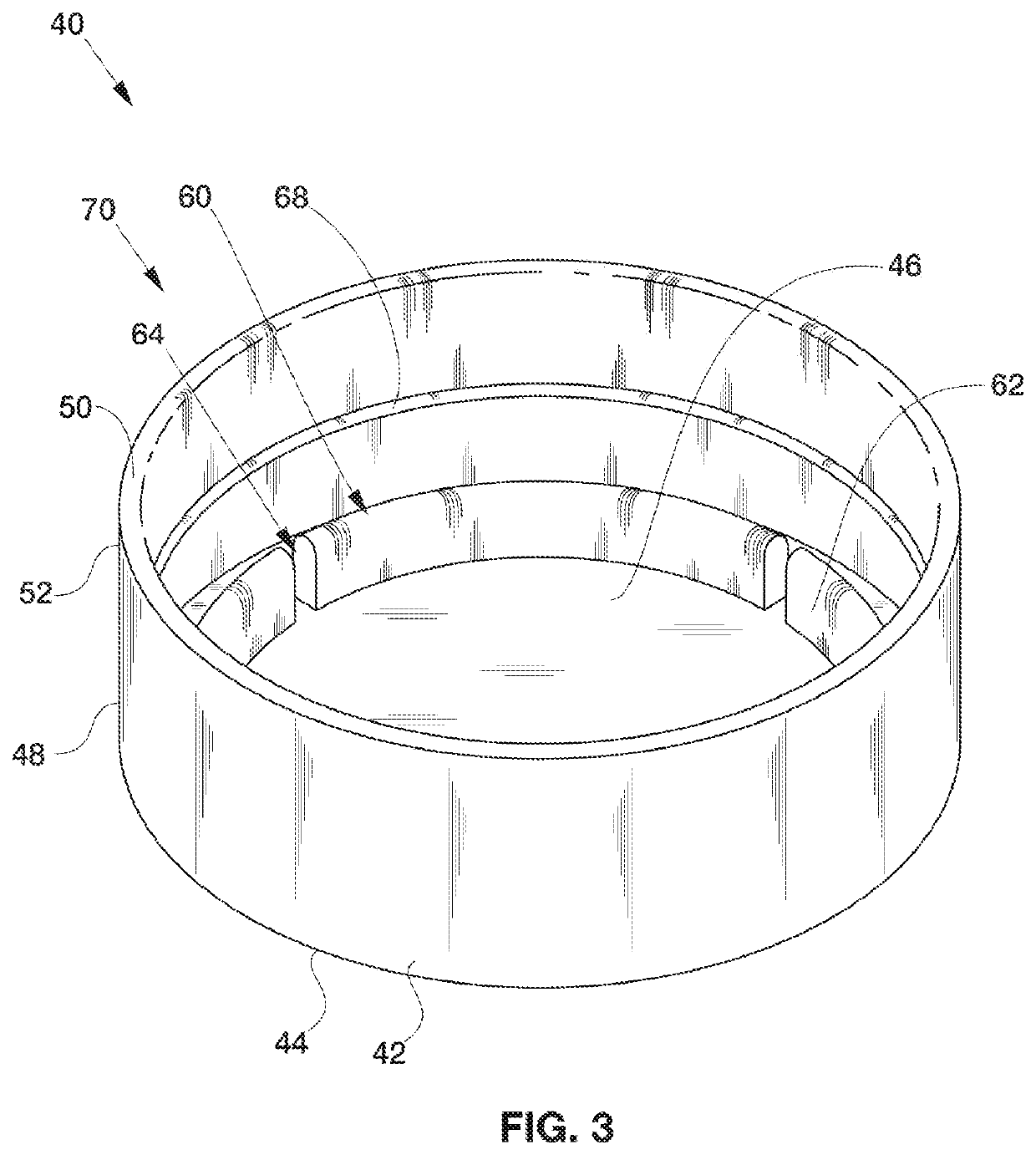

[0072]Turning to FIGS. 4A-C, a cross section of the lid 40 is illustrated in further detail. Notably, the polymeric base 70 of the lid 40, which includes at least the laterally extending wall 42 and the sidewall 48, supports a metallic cladding 80 engaged with the wall 42 so as to extend laterally across the outer surface 44 of the wall.

[0073]The cladding 80 comprises a metallic material, such as tin, brass, bronze, nickel, aluminum, steel, or tin coated steel plate. The cladding 80 may be formed from a single sheet of metal via punching, stamping, trimming, forming the sheet of metal and / or via other operations. Providing a metallic cladding 80 engaged with a polymeric base 70 may be advantageous in that the illustrated combination may provide an aesthetically appealing appearance by using a metallic material to form the prominent merchandizing portion of the container 10, while also allowing the remainder of the base 70 and container to be less expensively produced using, for exa...

second embodiment

[0081]FIGS. 5A and 5B show a lid 40a according to the present disclosure. The interior of the lid 40a may be substantially similar to the lid 40 discussed above, and as a result, the lid 40a may be configured to engage the body 20 in the same manner as discussed above.

[0082]The lid 40a illustrates the cladding 80a extending across substantially the entirety of the top surface 44 of the wall 42. Particularly, in the illustrated embodiment, the top surface 44 of the polymeric base 70 is substantially entirely hidden from view by the cladding 80a. The cladding 80a may include an adhesive layer 84, coated thereon in advance, that may be active by heat through an induction bonding machine as discussed hereinabove.

third embodiment

[0083]FIGS. 6A and 6B show a lid 40b according to the present disclosure. The interior of the lid 40b may be substantially similar to the lid 40 discussed above, and as a result, the lid 40b may be configured to engage the body 20 in the same manner as discussed above.

[0084]In the illustrated embodiment of FIGS. 6A and 6B, the cladding 80b is engaged with the wall 42 using an adhesive layer 84, such as the induction bonded, heat seal coating layer described above.

[0085]The wall 48 of the base 70b may also include a groove 49 recessed in the exterior surface 52. The groove 49 may be configured to receive the peripheral edge 86 of the cladding 80b. In the illustrated embodiment, the peripheral edge 86 may be bent or otherwise angled to reside in the groove 49. By positioning the peripheral edge 86 within the groove 49, the cladding 80b may be less susceptible to peeling away from the base 70b. The depth of the groove 49 in the radial direction toward axis C may be selected such that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com