Fabrics woven by spread tow yarns consisting of polymer matrix composite and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

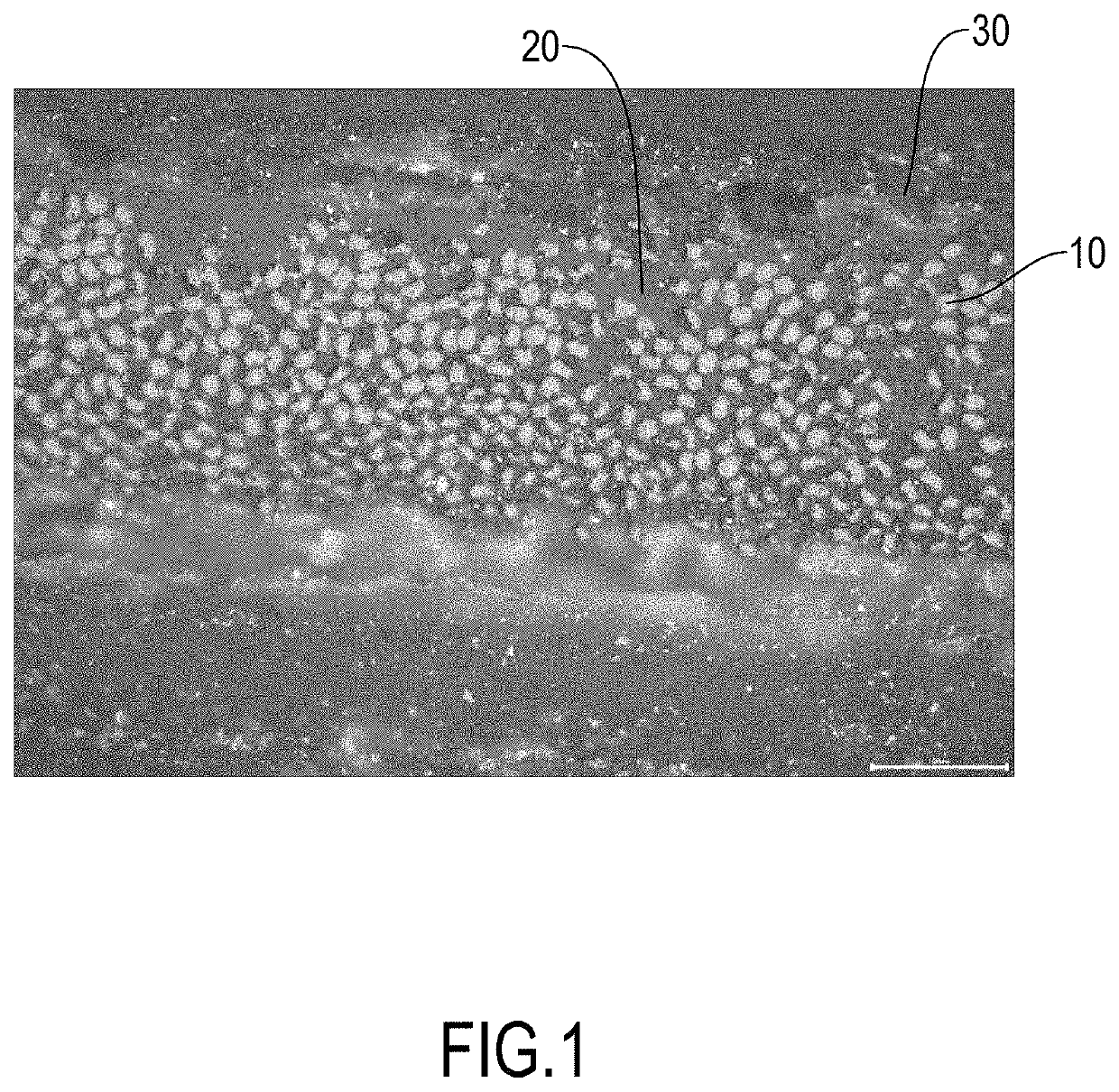

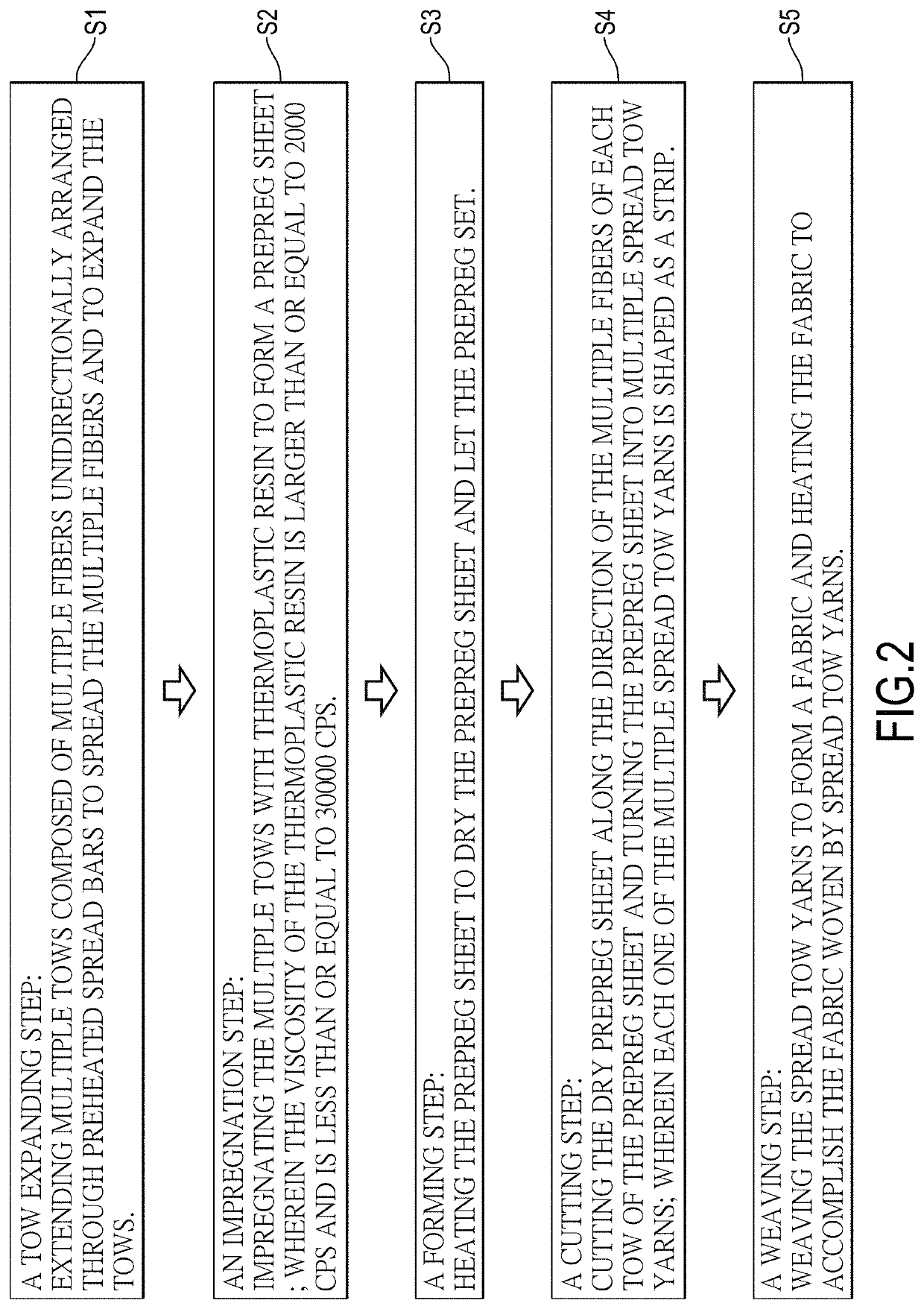

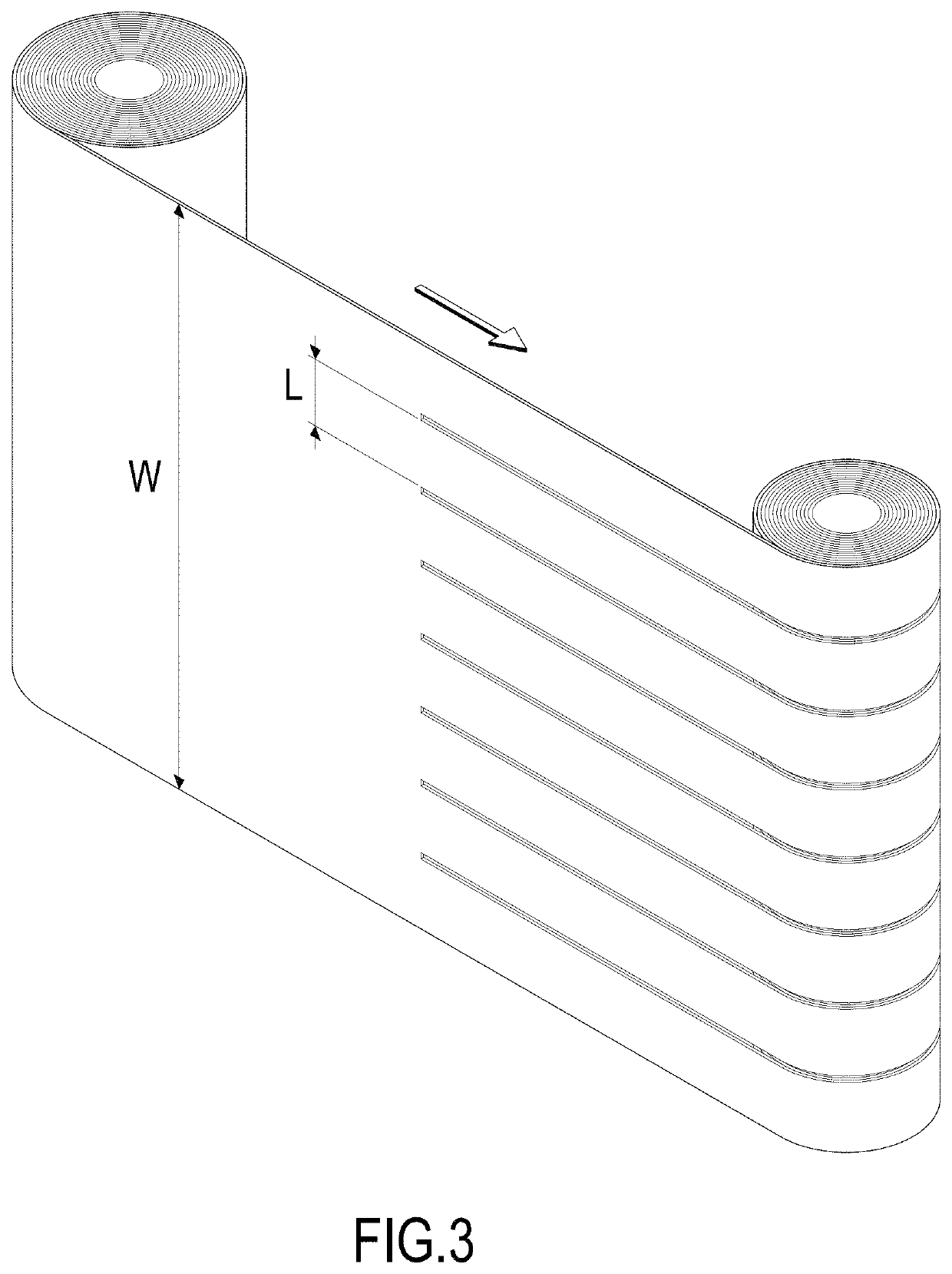

[0012]With reference to FIG. 2, a method for producing fabrics woven by spread tow yarns in accordance with the present invention has a tow spreading step S1, an impregnation step S2, a forming step S3, a cutting step S4, and a weaving step S5.

[0013]Each one of multiple tows has multiple fibers 10 unidirectionally arranged. In the tow expanding step S1, the multiple tows extend through preheated spread bars. The spread bars provide the multiple fibers 10 with tension to spread the multiple fibers 10 and expand the width of each tow to a required value. The temperature of each one of the spread bars is higher than or equal to 80° C. and is less than or equal to 120° C. An angle defined between the horizon and each one of the fibers 10 is larger than or equal to 10° and is less than or equal to 70° . The multiple fibers 10 are spread, and each one of the tows turns into a flat tow with unidirectional fibers 10.

[0014]In the impregnation step S2: multiple tows that have been flattened a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com