Variable Temperature Blender

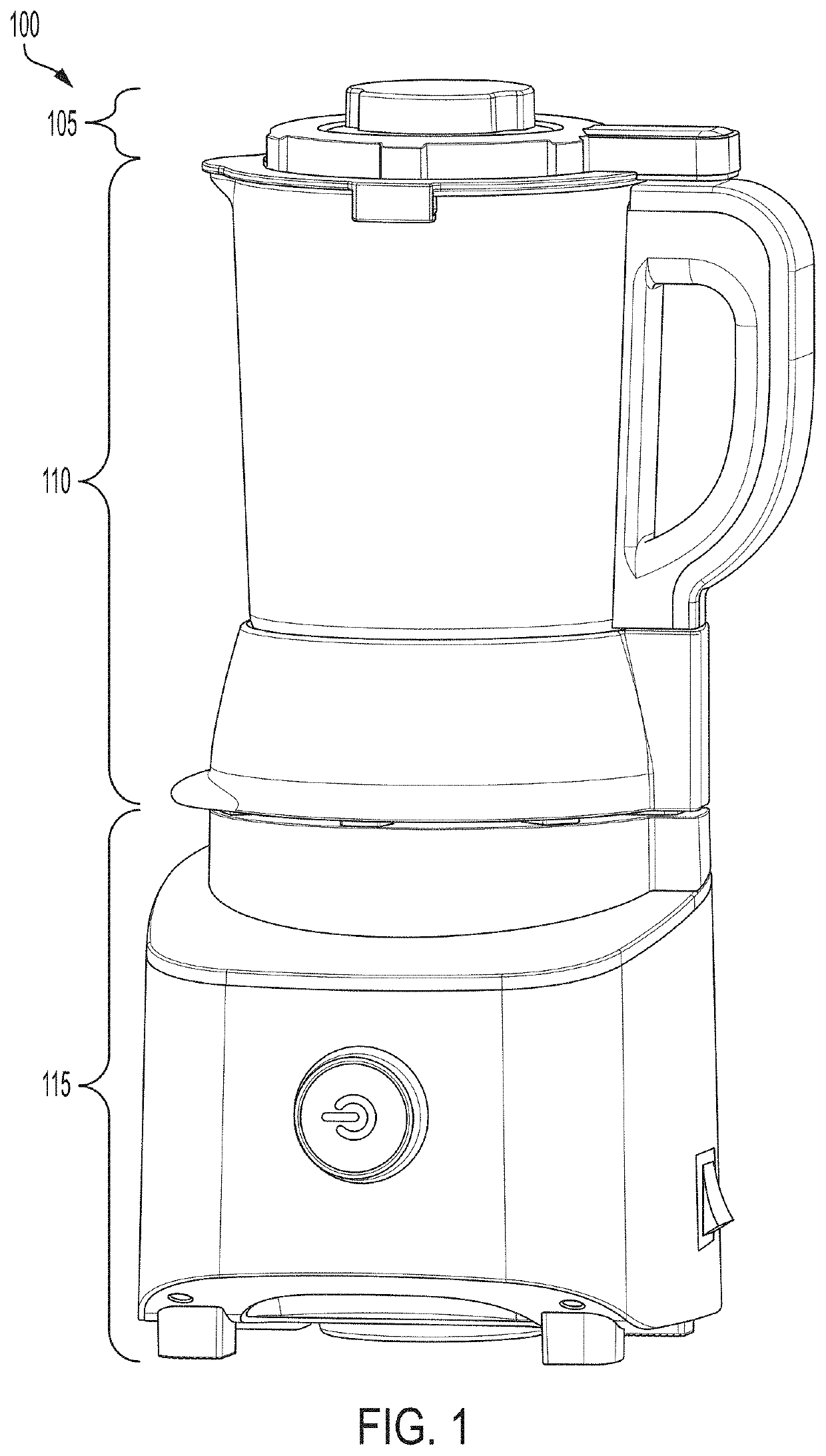

a blender and variable temperature technology, applied in the field of variable temperature blenders, can solve the problems of difficult to determine the best setting and precise function of the blender, and the blender itself is not ideal for preparing hot or heated ingredients,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

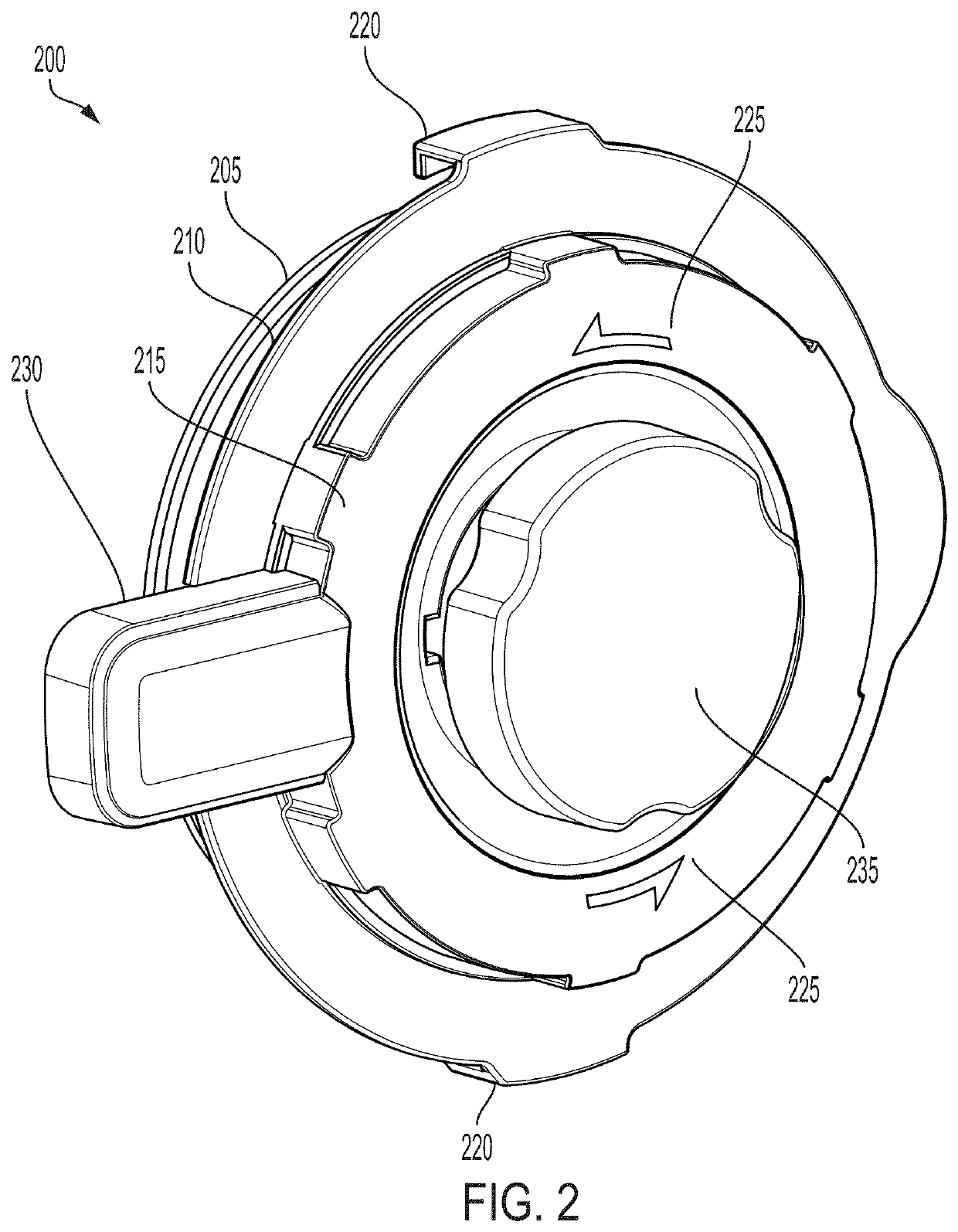

embodiment 200

[0028]FIG. 2 shows an embodiment 200 of the lid assembly (105) of the variable temperature blender (100). The lid assembly 200 may include a lid 205 having an outer lid circumferential portion 210 and an inner raised lid portion 215. The outer lid circumferential 210 portion may extend to a greater diameter than the vessel assembly (110) upon which the lid assembly 200 can rest and attach. A plurality of lid notches 220 may be positioned on the edges of the outer lid circumferential portion 210. The plurality of lid notches 220 in an embodiment of the disclosure may have an L shaped design and positioned approximated 180 degrees from one another. The lid assembly 200 disclosed in FIG. 2 has two lid notches 220, however other variations and numbers of notches may also be used. When the lid assembly 200 is placed on top of the vessel assembly (110), the lid assembly 200 may be rotated to lock the plurality of lid notches 220 with the vessel assembly (110).

[0029]The inner raised lid po...

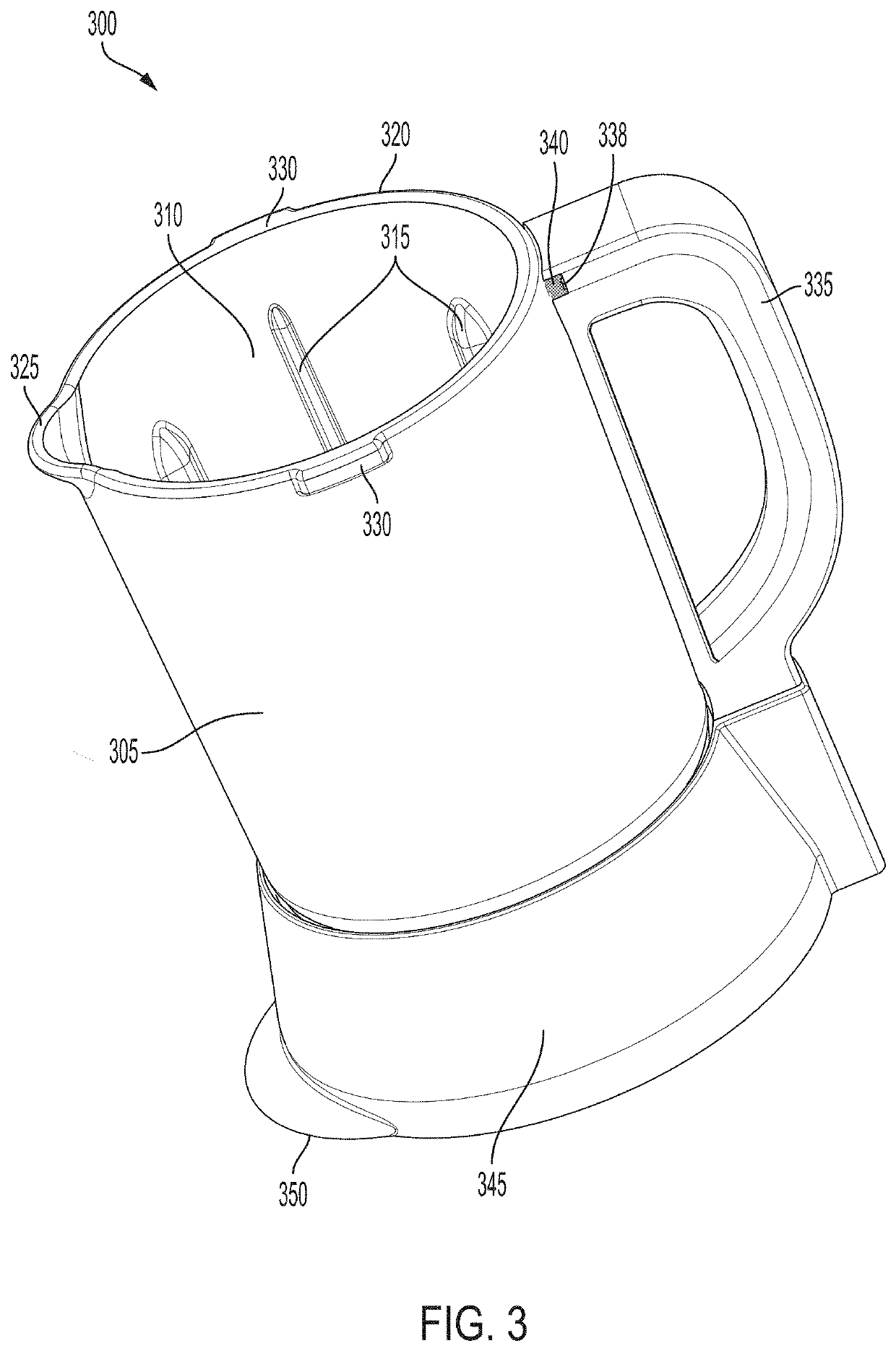

embodiment 300

[0032]Turning now to FIG. 3, a perspective view of an embodiment 300 of the vessel assembly (110) of the variable temperature blender (100) is shown. The vessel assembly 300 may include a blending vessel 305 having a hollow interior volume 310. The blending vessel 305 provides a space to house food ingredients and liquids for mixture during operation of the variable temperature blender 100. The blending vessel 305 may be made of a glass material, although it should be understood that other materials may be sufficient, such as but not limited to, stainless steel or plastic polymers. The blending vessel 305 may contain grooves 315 on the interior walls to aid in the blending process by preventing excess food particle build up on the interior walls as the variable temperature blender 100 is in operation. A top rim 320 of the blending vessel 305 can be configured to mate with the shape of the lid assembly 200 disclosed above and described / shown in earlier figures. In some embodiments, t...

embodiment 400

[0035]Turning now to FIG. 4, a bottom perspective view of an embodiment 400 of a bottom of the vessel assembly (300) is shown, with the vessel electrical interface 405 being visible. In an embodiment of the disclosure, the vessel electrical interface 405 is a male pin configuration that can mate with the base assembly (115). The vessel electrical interface 405 is in communication with the lid switch (338), a heating element, and a temperature sensor 408 of the vessel assembly (300). The vessel electrical interface 405 passes power and data signals through these connections to allow for correct operation of the variable temperature blender (100) at the selected mode of operation and also adjusts the temperature of the heating element based on the selected mode of operation.

[0036]A plate 410 of the vessel assembly (300) is also shown. The plate 410 is made of any type of thermally conductive material and provides a barrier between the interior of the blending vessel and the interior o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com