Flexible insulating sheet

a flexible and sheet technology, applied in the field of insulation sheets, can solve the problems of reducing the shear modulus of the twin-wall sheet in both longitudinal and transverse directions, unsuitable for many applications requiring a curved or flexible panel, and acrylic or high-density pvc, so as to achieve the effect of maintaining rigidity and minimizing bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail preferred embodiments of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspects of the invention to the embodiments illustrated.

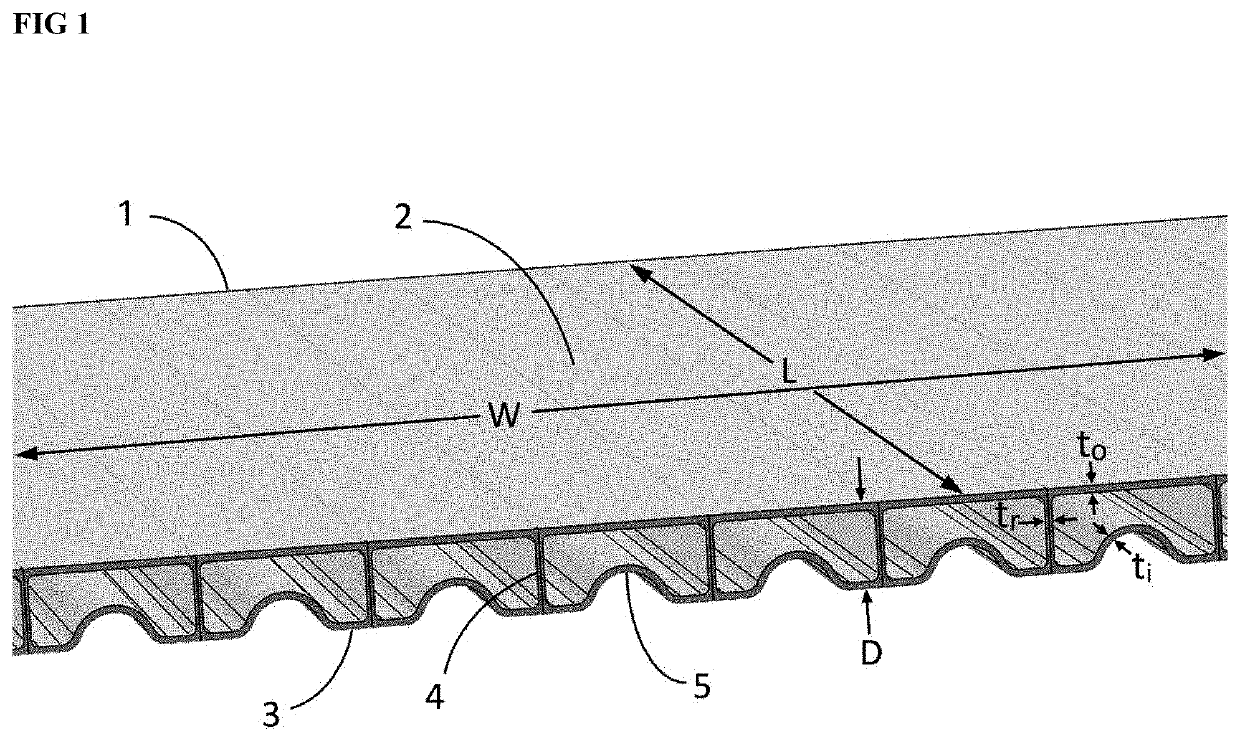

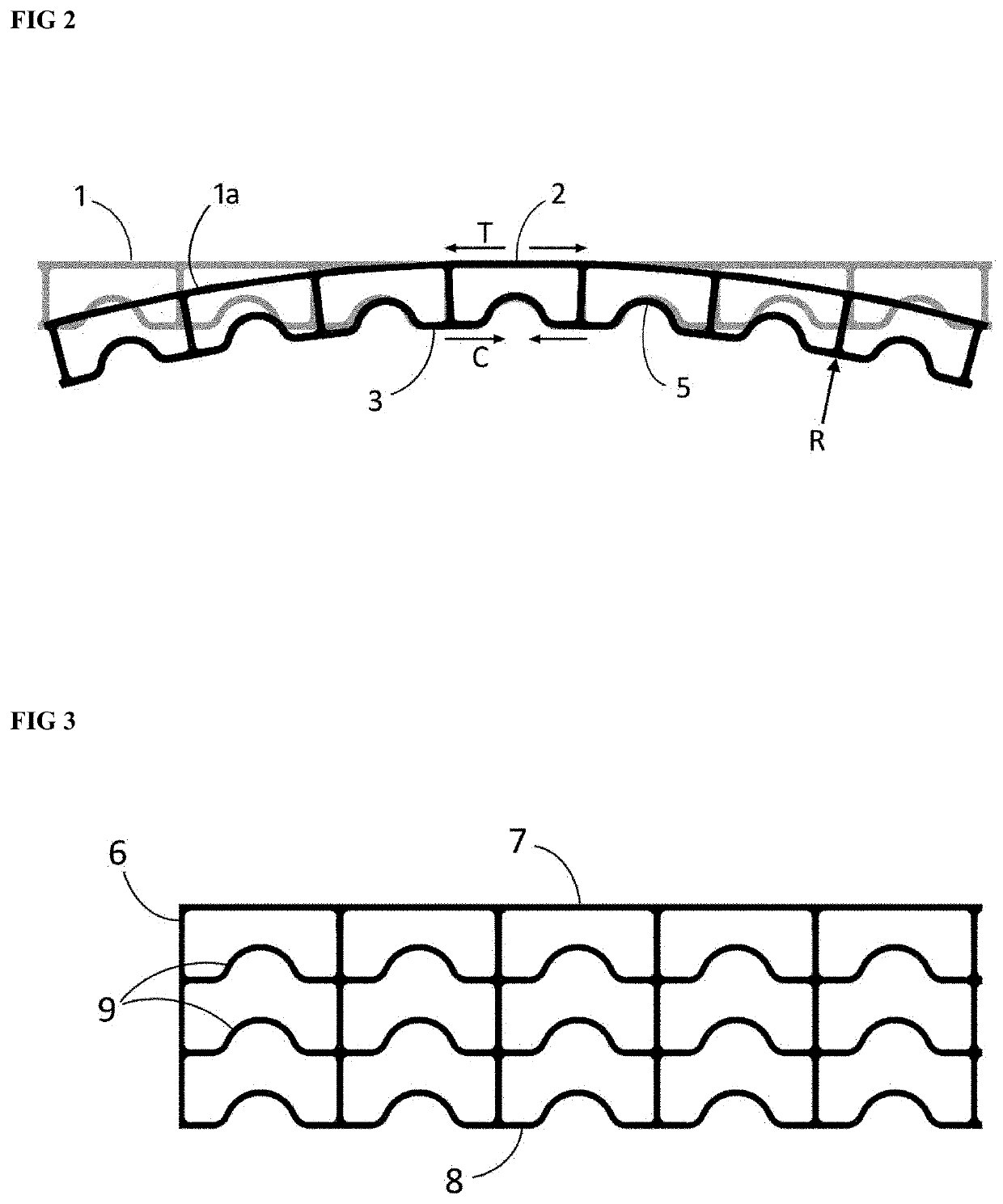

[0026]The present invention is a twin-wall sheet that incorporates a generally flat outer wall and a contoured inner wall.

[0027]Referring to FIG. 1, an orthogonal view of the present invention 1 in a flat, or un-flexed, position is shown. The twin-wall sheet is comprised of a first wall 2; a second wall 3 that is generally parallel to and of the same length and width as the first wall 2, and a plurality of ribs 4 located at periodic intervals between, perpendicular to, and attached to the first wall 2 and second wall 3 to establish the overall thickness of the twin-wall sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com