Transparent wood composite, systems and method of fabrication

a technology of transparent wood and composite materials, applied in the field of light-transmitting systems, can solve the problems of inconvenient manufacturing, inconvenient processing, and inability to meet the needs of the user, and achieve the effects of improving thermal insulation and daytime light harvesting, and energy-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

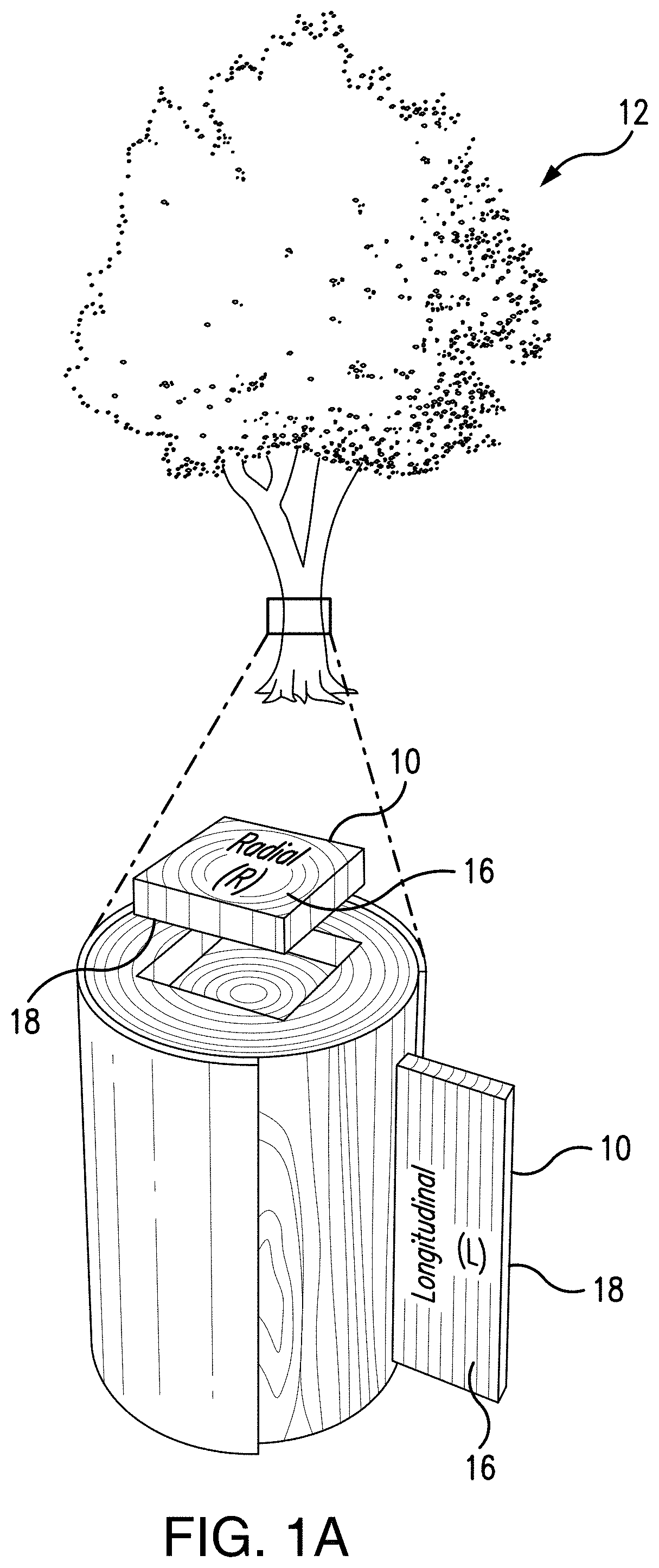

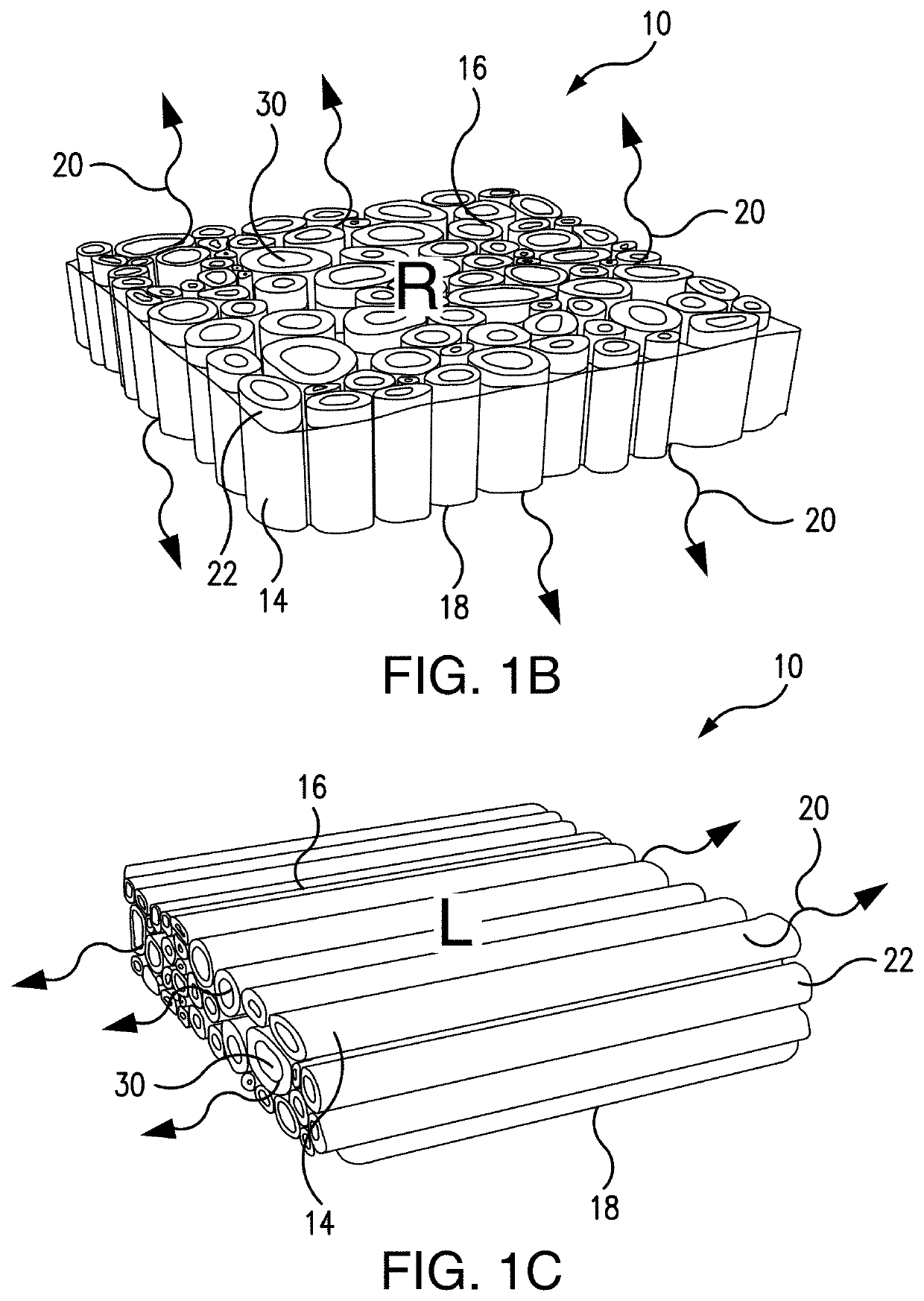

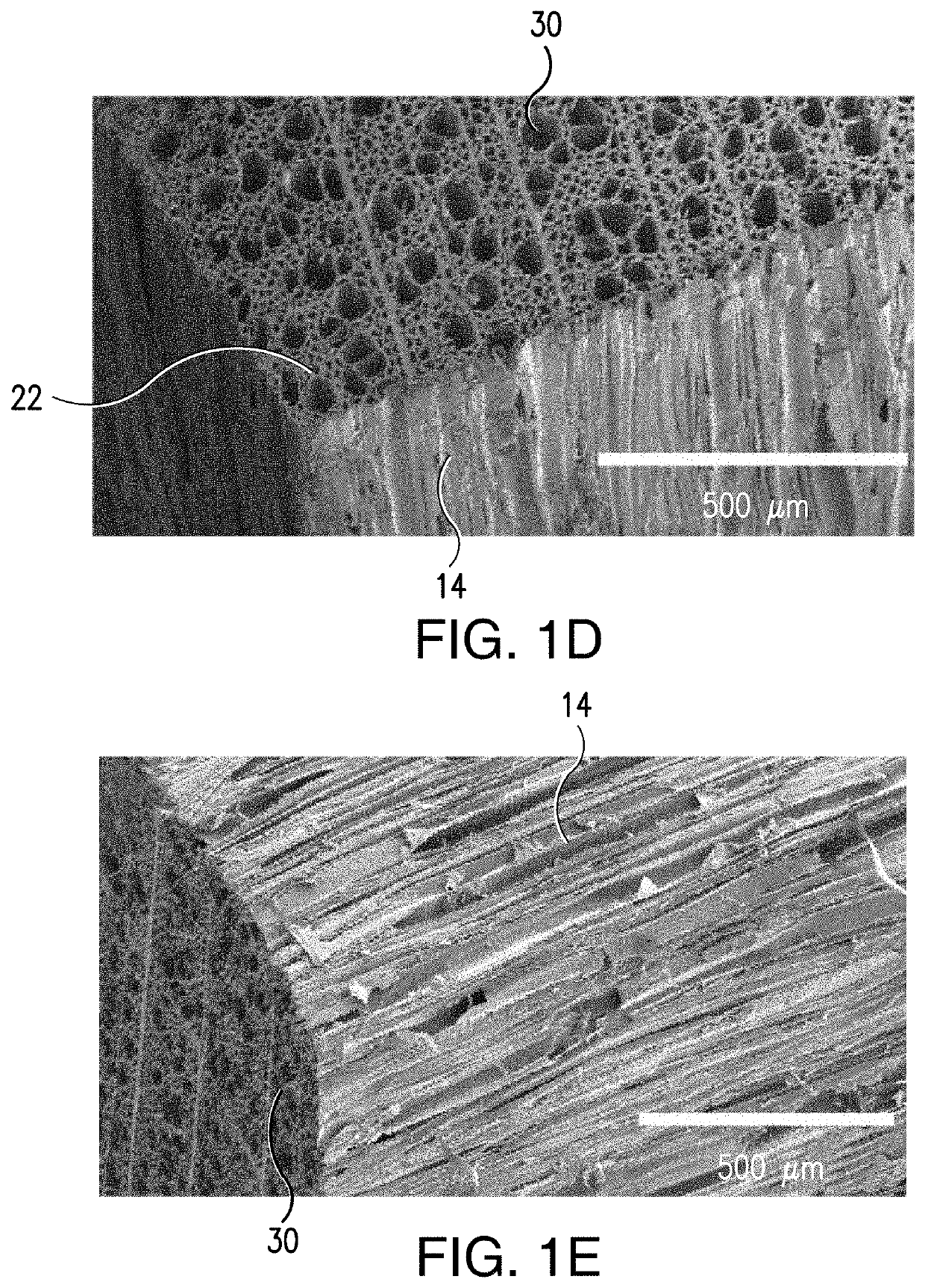

[0083]Referring to FIGS. 1A-1H and 2A-2G, the transparent wood composites were fabricated by efficient and simple process including removing the light absorptive lignin to form the lignin-devoid wood block (in the first manufacturing stage best shown in FIGS. 1F and 2D), and backfilling the nano / microsized channels in the lignin-devoid wood block with index-matching polymers (in the subsequent second manufacturing stage best shown in FIG. 2E). By filling the channels with the properly selected polymer(s), the refractive index (RI) mismatch can be greatly reduced and the light reflection can be suppressed to increase the wood sample transparency.

[0084]The well-defined internal channels in the natural wood have a low tortuosity, which permits rapid removal of the colored lignin deposited inside the internal channels. After lignin removal, the open internal channels allow fast infiltration by the polymer(s) to decrease the light scattering and increase the mechanical strength of the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap