Method and apparatus for maintaining product availability during a disturbance in an air separation unit

a technology of air separation unit and product availability, which is applied in the direction of lighting and heating apparatus, solidification, refrigeration and liquifaction, etc., can solve the problems of affecting the purity profile, less use, and affecting the final product purity, so as to reduce the stable flow rate load and minimize the rate of change in airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

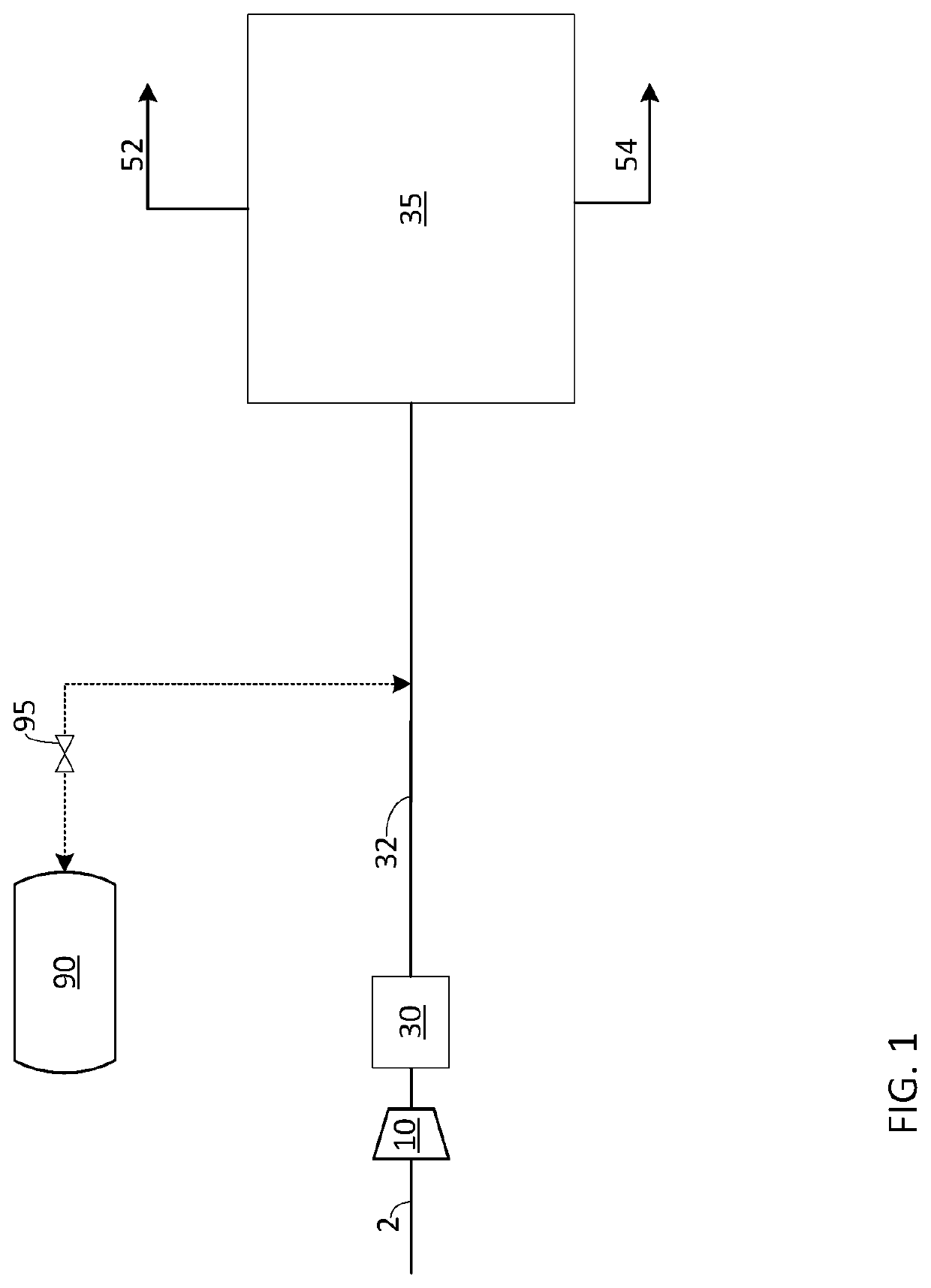

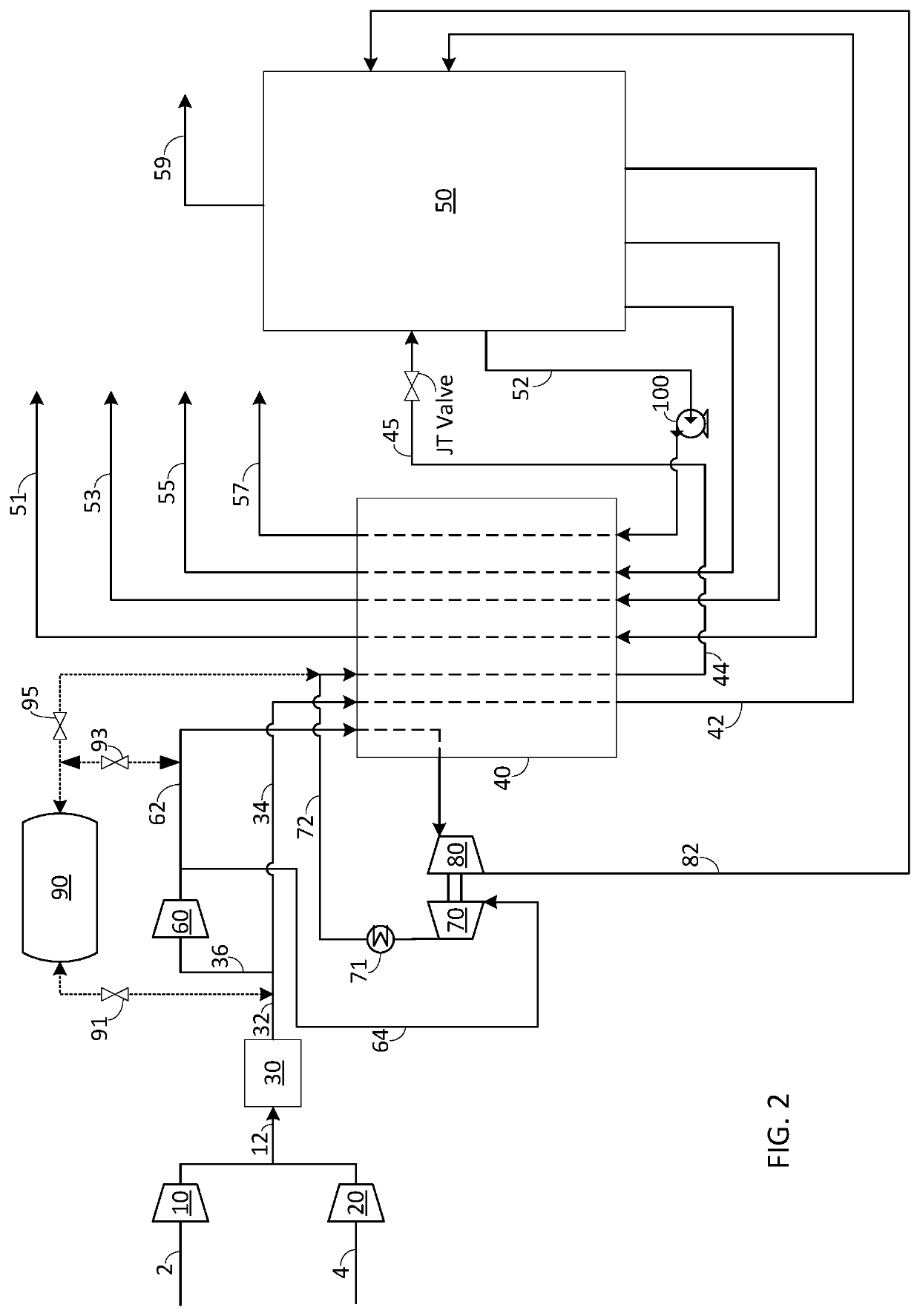

[0026]Certain embodiments of the invention allow the ability to continue to send compressed and purified air to the cold box even after a potential MAC trip for a period of time. This can be useful for allowing (a) gradual and more controlled transition to reduced production load without a backup system, (b) normal air flow rates to cold box during gradual startup of a backup system, or (c) gradual shutdown of production to customer, thereby allowing the customer a more controlled shutdown process.

[0027]As noted previously, ASUs can have various MAC arrangements—including single or multiple MACs, with different load configurations. As expected, in instances in which a MAC that carries a lower overall load (e.g., 20% of total air flow), the perturbation of the overall process is less as compared to an instance where the 80% MAC tripped or even if the MACs were split evenly (e.g., 50%) and one tripped. As such, those of ordinary skill in the art will recognize that the volume of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com