Systems and methods for formulating or evaluating a construction admixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

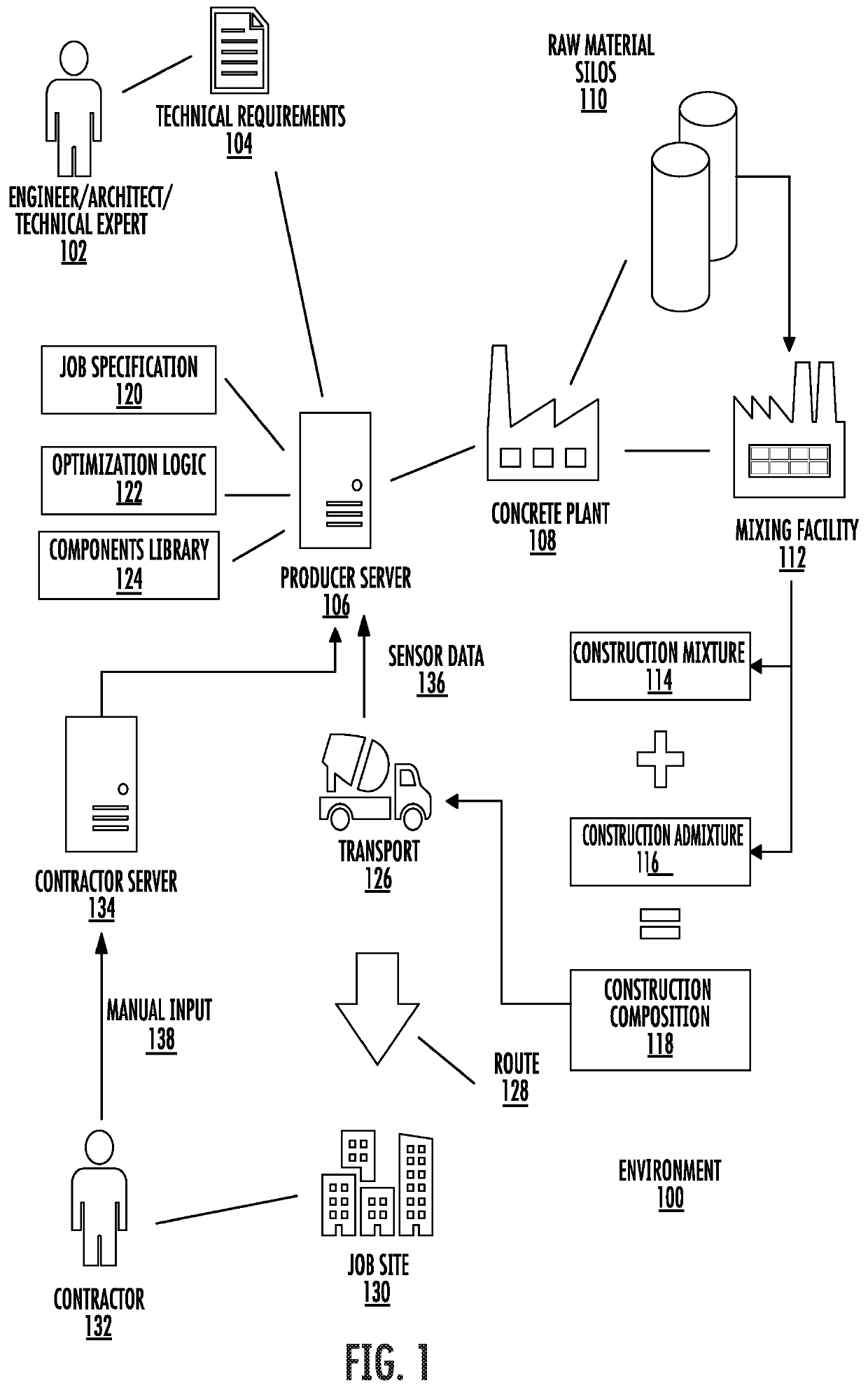

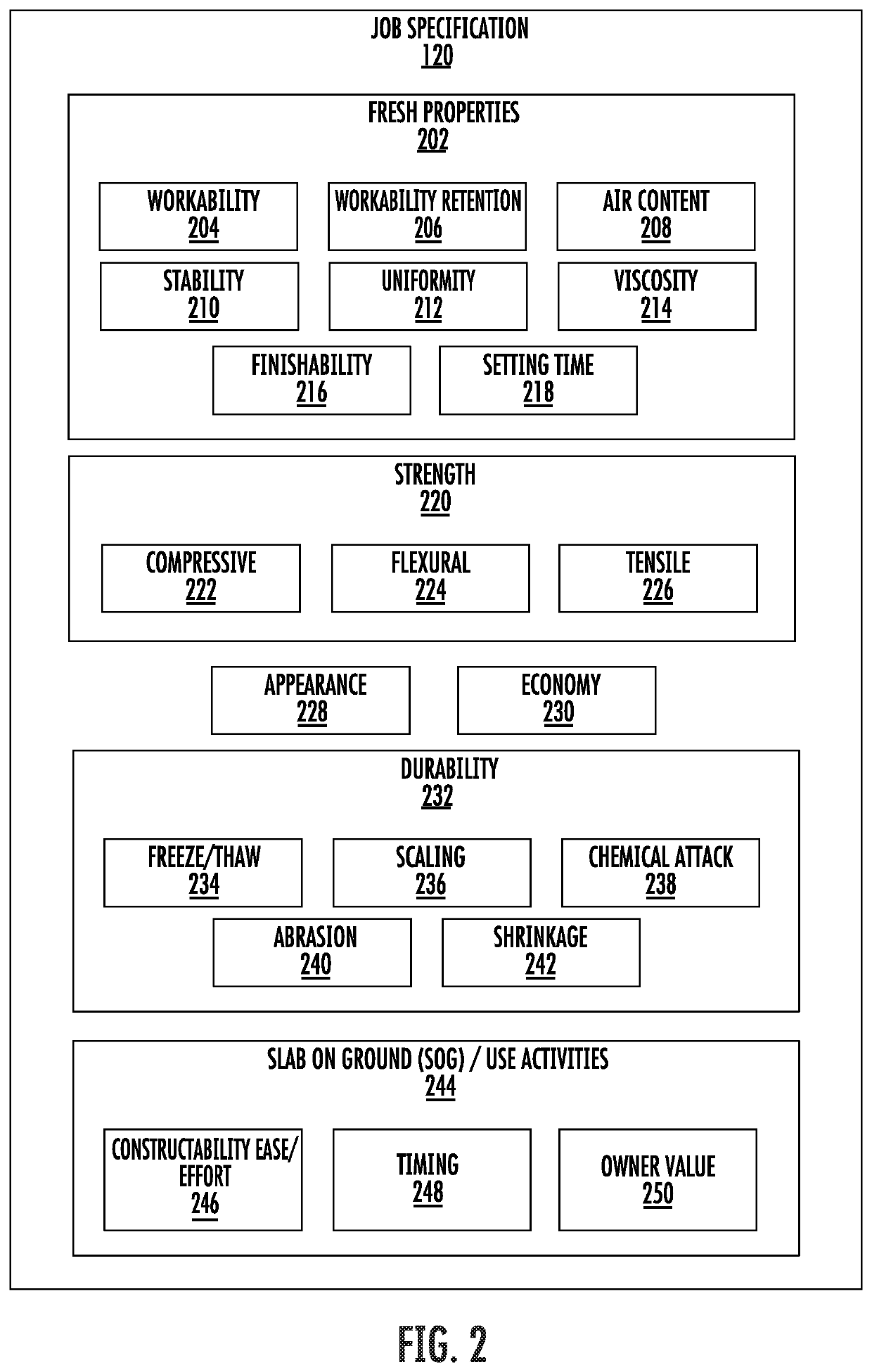

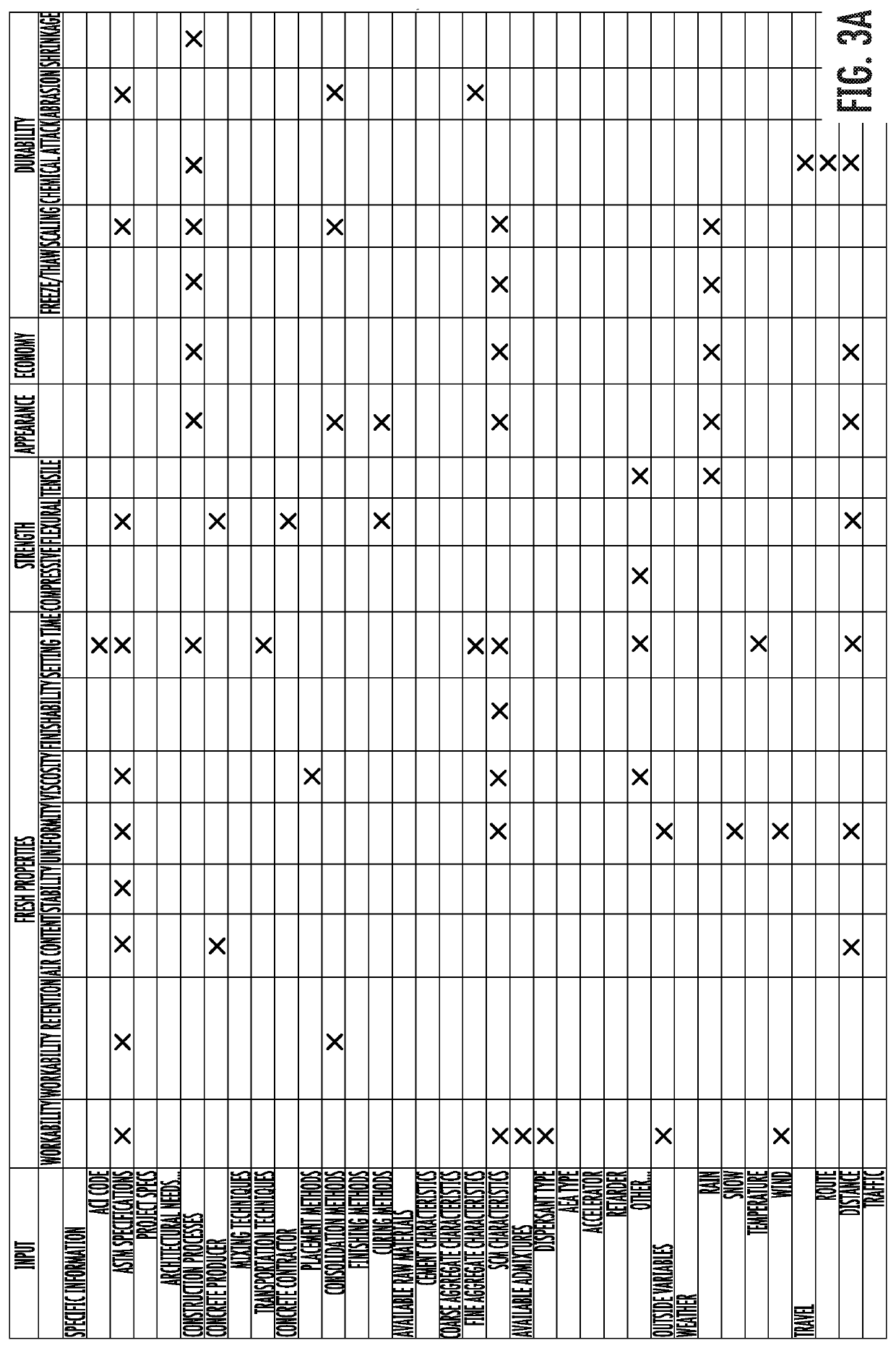

[0043]As described above, it can be difficult to formulate a construction composition to meet all the various requirements of an engineering project while accounting for other variables that may affect the availability or performance of the construction composition ingredients. The development of an optimal set of construction composition raw material proportions for a given project requires a high level of familiarity with the properties of the material being designed, translating project needs and details into a set of preferred characteristics, and familiarity with locally-available raw materials.

[0044]Conventionally, one solution has been to develop a small number of construction compositions having known performance ranges, and selecting from among the limited number of options available. This approach, however, has a number of limitations. First, the construction composition may not be optimally formulated for the conditions that will be present at the job site. Second, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com