Lean burn combustor

a combustible and burnt technology, applied in the direction of burners, combustion types, combustion processes, etc., can solve the problems of passenger discomfort, engine fatigue failure, etc., and achieve the effect of reducing nox and smoke, reducing fatigue failure, and maximizing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

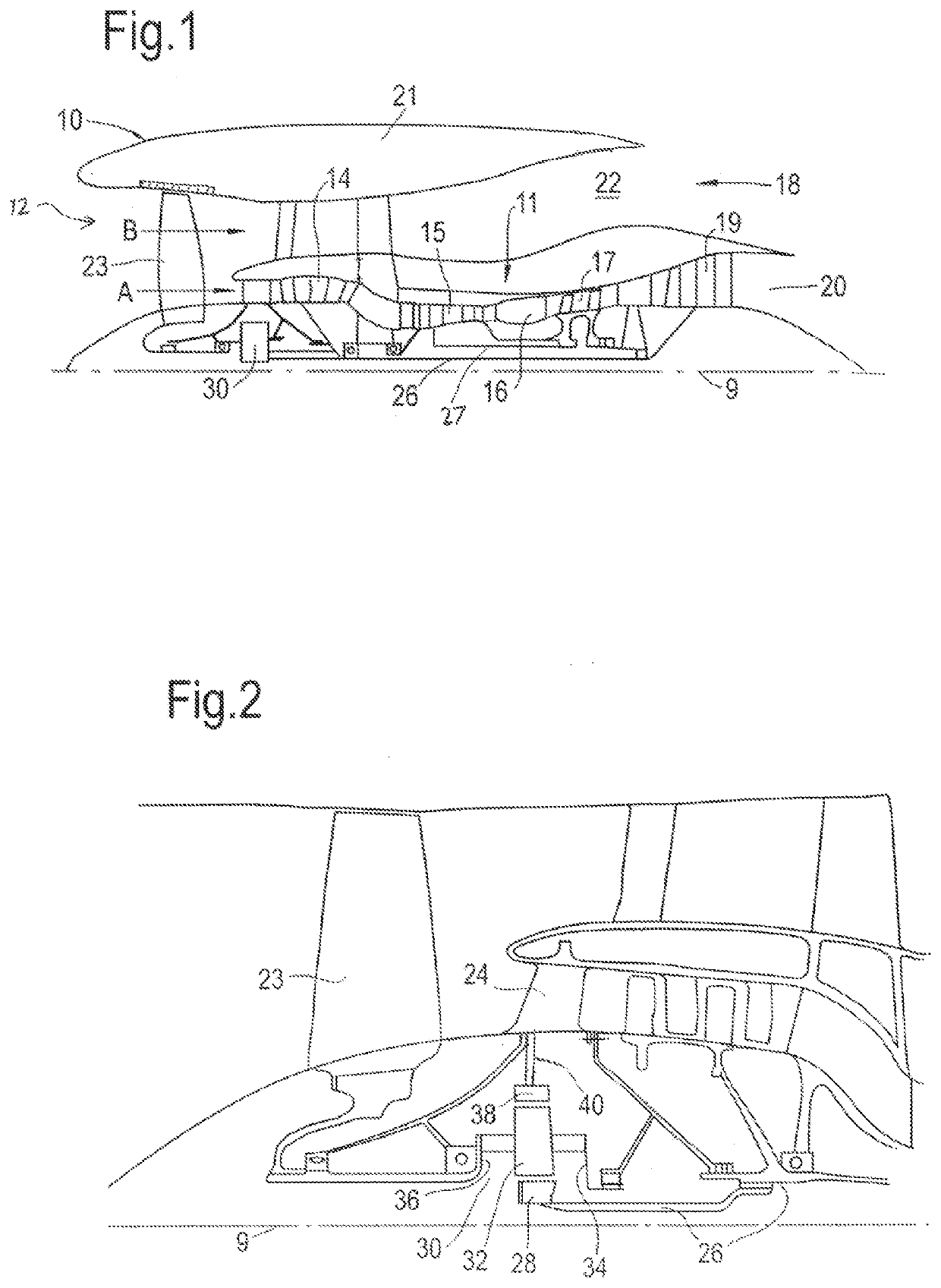

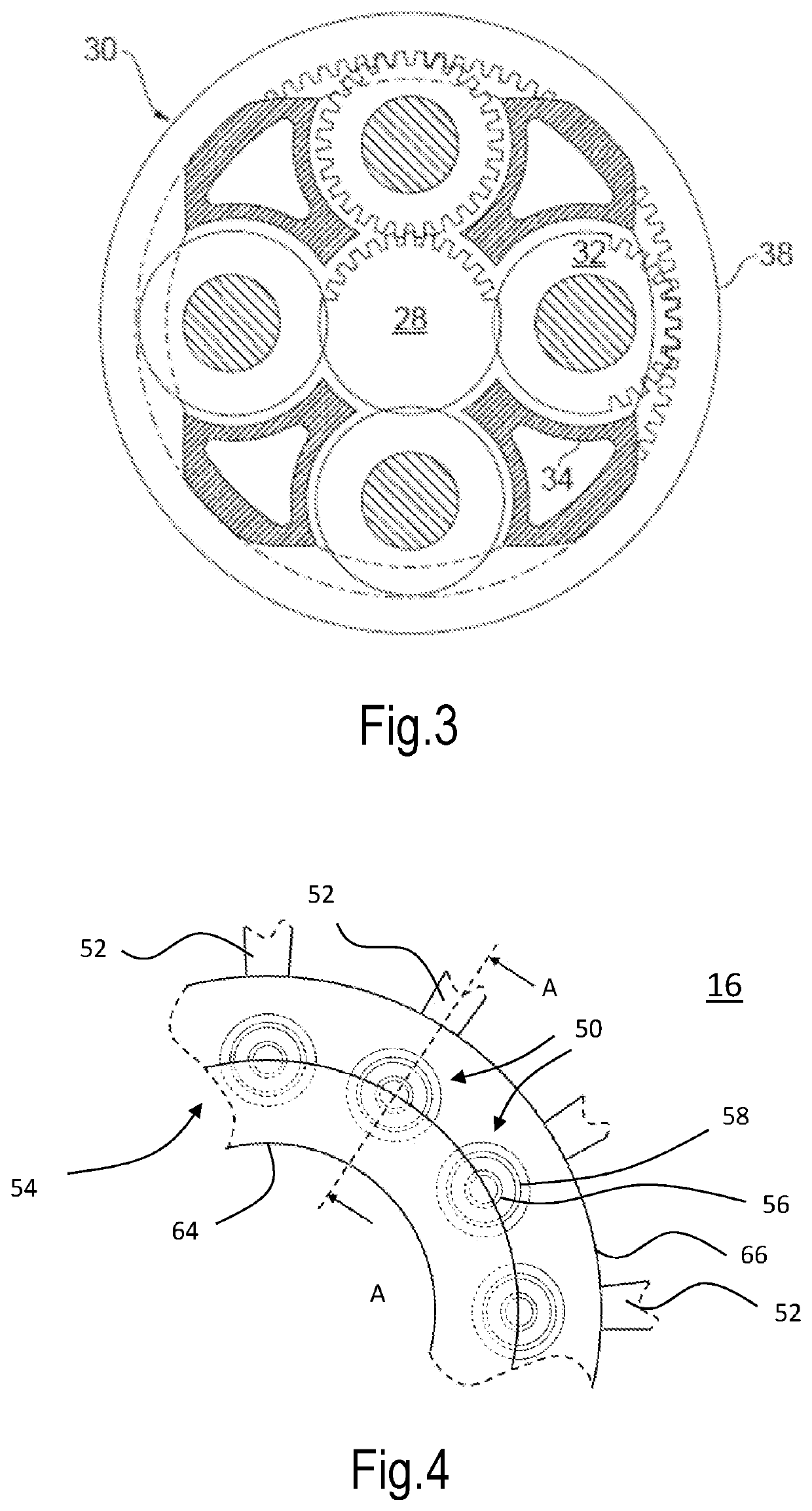

[0071]With reference to FIG. 1, a gas turbine engine, generally indicated at 10, has an engine principal rotational axis 9. The engine 10 comprises an air intake 12 and a propulsive fan with a plurality of fan blades 23 that generates two airflows: a core airflow A and a bypass airflow B. The gas turbine engine 10 comprises a core 11 that receives the core airflow A. The engine core 11 comprises, in axial flow series, a low pressure compressor 14, a high-pressure compressor 15, combustion equipment comprising a lean burn combustor 16, a high-pressure turbine 17, a low pressure turbine 19 and a core exhaust nozzle 20. A nacelle 21 generally surrounds the gas turbine engine 10 and defines a bypass duct 22 and a bypass exhaust nozzle 18. The bypass airflow B flows through the bypass duct 22. The fan is attached to and driven by the low pressure turbine 19 via a shaft 26 and an epicyclic gearbox 30.

[0072]In use, the core airflow A is accelerated and compressed by the low pressure compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com