Castable infrared illuminant compositions

a technology of infrared illumination and compositions, which is applied in the field of infrared illumination compositions, can solve the problems of high visible light output, severe limit the amount of fuels that can be used, etc., and achieve the effects of poor high temperature aging, low burn rate, and little visible ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

In this example a composition within the scope of the present invention was formulated and tested. A castable composition was formulated. The formulation included relatively high levels of CsNO.sub.3.

The Witco Binder Premix comprised a mixture of WITCO 1780 liquid polyester (triethyleneglycol succinate), manufactured by Witco Corp, blended with an appropriate amount of an epoxy curing agent to provide adequate cure.

The material was burned and the burn rate, output of visible light, and output of infrared radiation measured. Visible light was measured with a silicon photodiode with photopic response.

Infrared light was measured using a silicon cell with a 695 nm cut on filter.

Tests on the composition yielded the following data:

All data represent the average of two runs.

As can be seen from the data presented above, the composition provides a useful infrared emitting composition. The composition provides a rapid burn rate, along with high IR output and extremely low visible output.

example 2

In this Example a composition within the scope of the present invention was formulated and tested. The following ingredients were mixed to produce an infrared emitting composition:

The composition was a castable composition and was burned as a flare 2.75 inches in diameter, 13.1 inches in length, and weighing approximately 5.5 pounds. The following results were obtained and are the average for four separate tests:

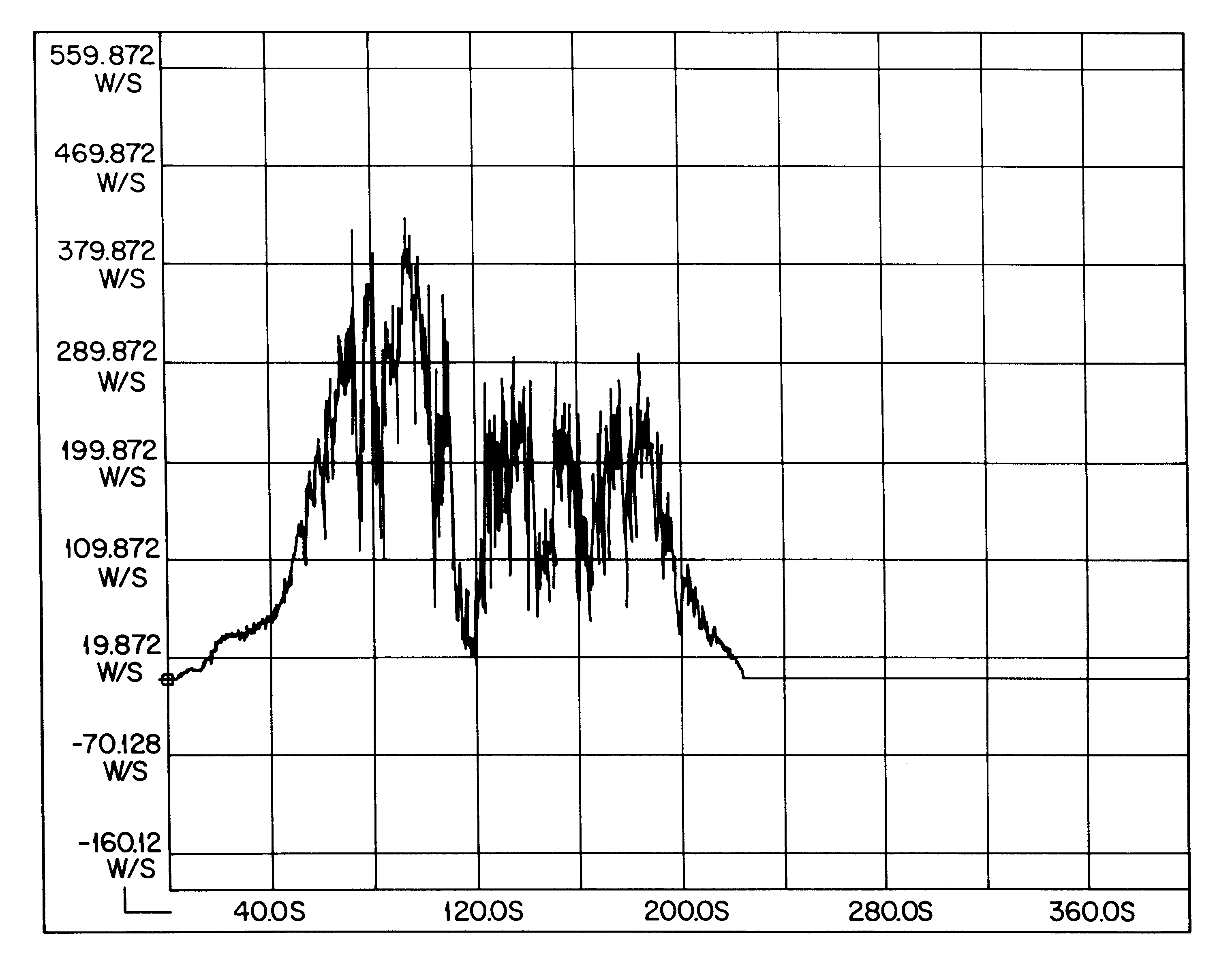

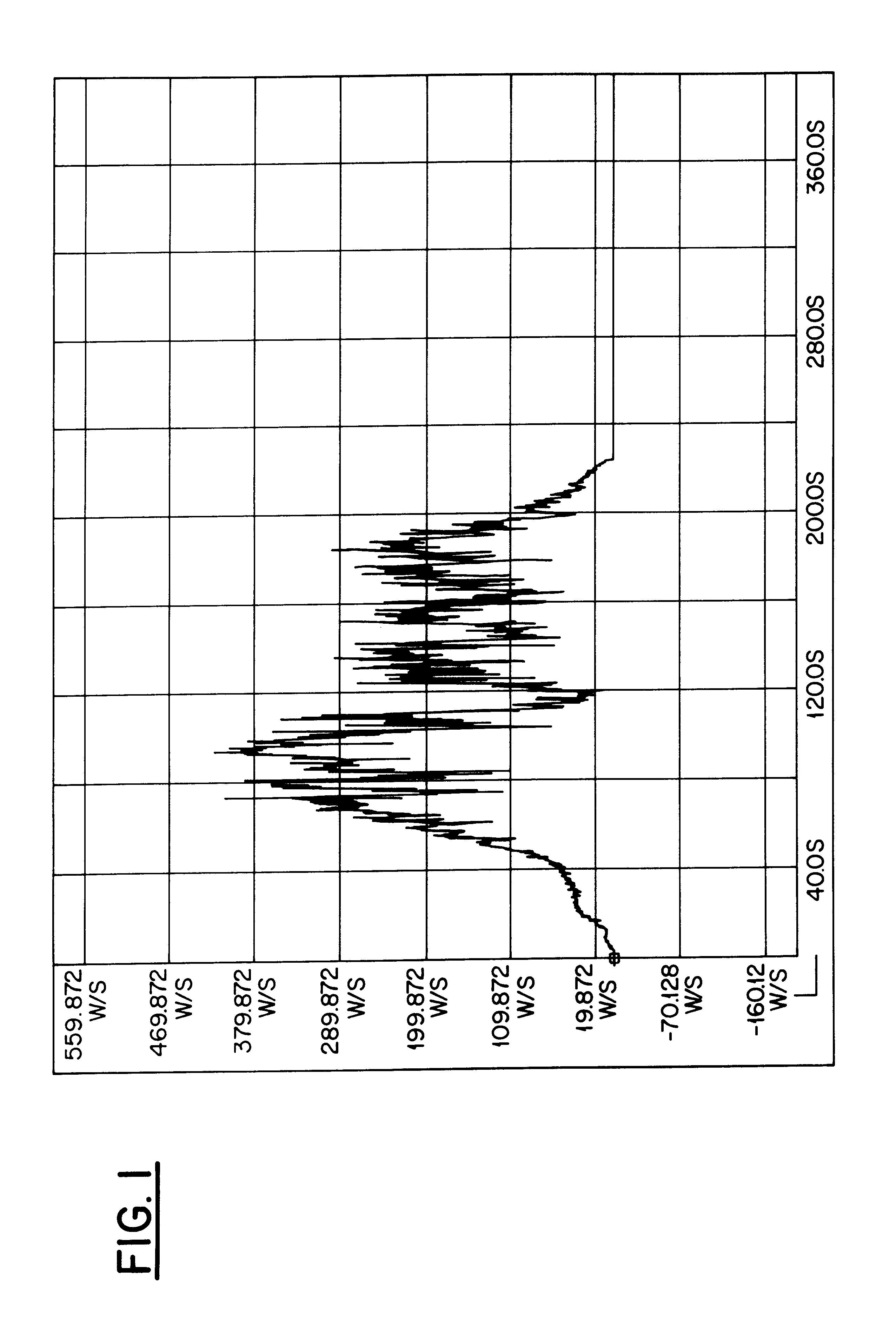

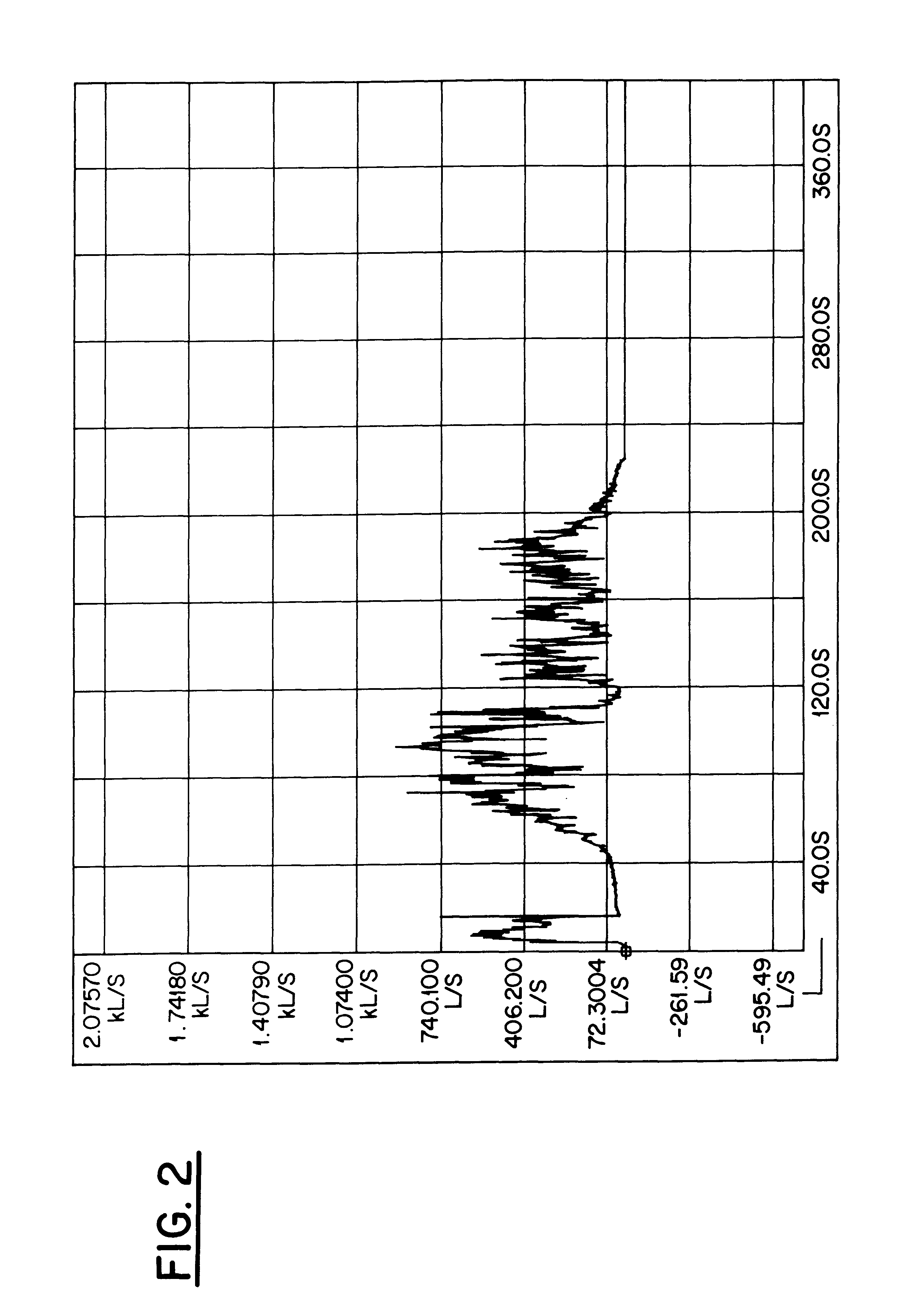

FIG. 1 is plot of the output of infrared radiation over time for the composition. FIG. 2 is a plot of the output of visible radiation over time for the composition. It can be seen that a high level of infrared output was achieved shortly after burning commenced. This level was sustained over most of the operation of the sample, declining at the end of the burn. This burn rate curve is desirable. At the same time, the ratio of IR to visible was excellent.

It can be appreciated from the results achieved that an acceptable infrared emitting composition was produced and that the ...

example 3

In this Example a composition within the scope of the present invention was formulated and tested. The following ingredients were mixed to produce an infrared emitting composition:

This castable composition was burned and the following results were obtained and are the average for four separate tests:

FIG. 3 is plot of the output of infrared radiation over time for the composition. FIG. 4 is a plot of the output of visible radiation over time for the composition. It can be seen that a high level of infrared output was achieved shortly after burning commenced. This level was sustained over most of the operation of the sample, declining at the end of the burn. This burn rate curve is desirable. At the same time, the ratio of IR to visible was excellent.

It can be appreciated from the results achieved that an acceptable infrared emitting composition was produced and that the level of visible emissions was significantly lower than the level of infrared emissions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com