Electronically commutated DC motor comprising a bridge circuit

a bridge circuit and electric commutation technology, applied in the direction of multiple dynamo-electric motor speed regulation, synchronous motor starters, multiple dynamo-electric motors, etc., can solve the problem of raising the cost of circuit board manufacturing, and achieve the effect of easy and inexpensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

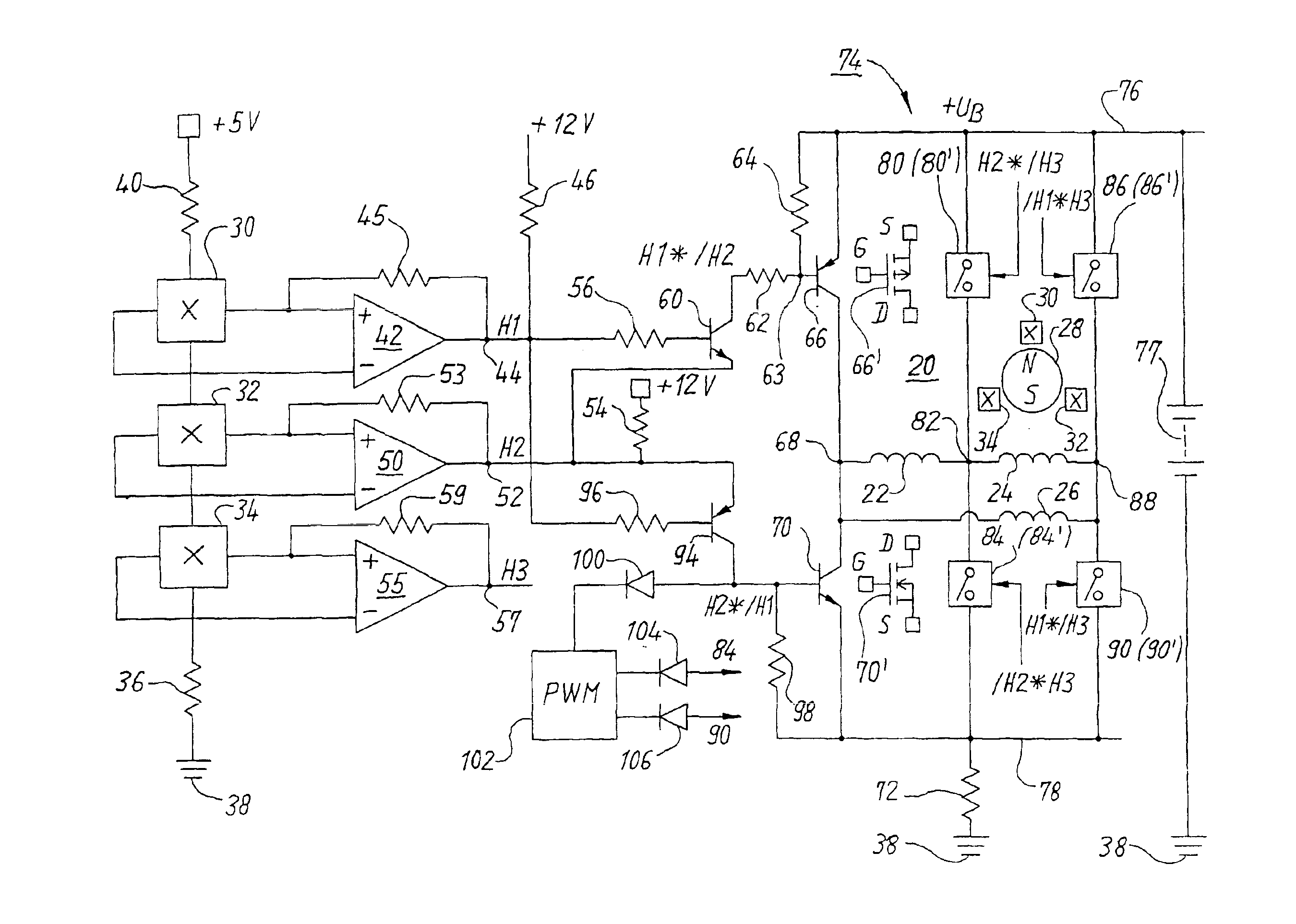

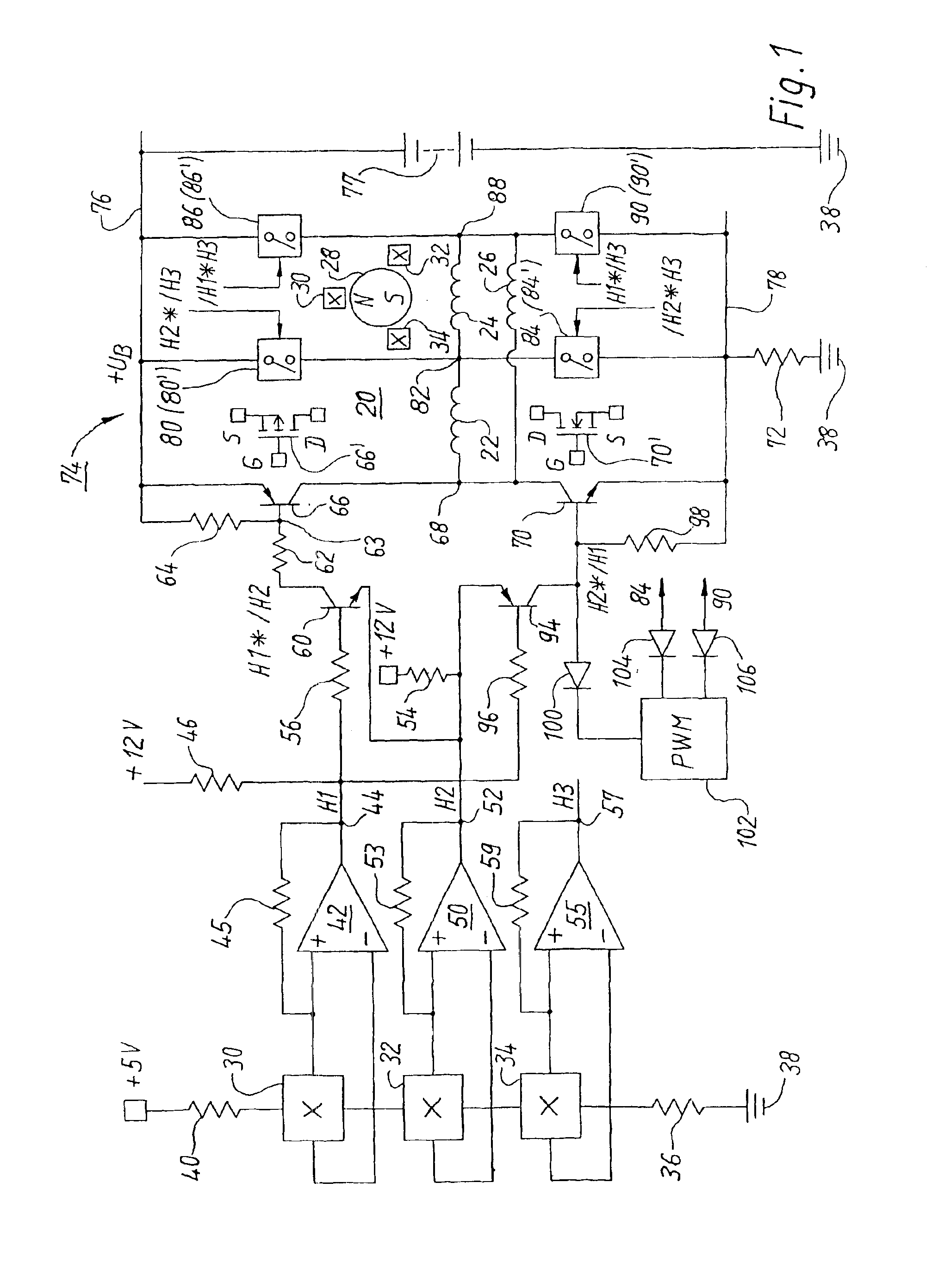

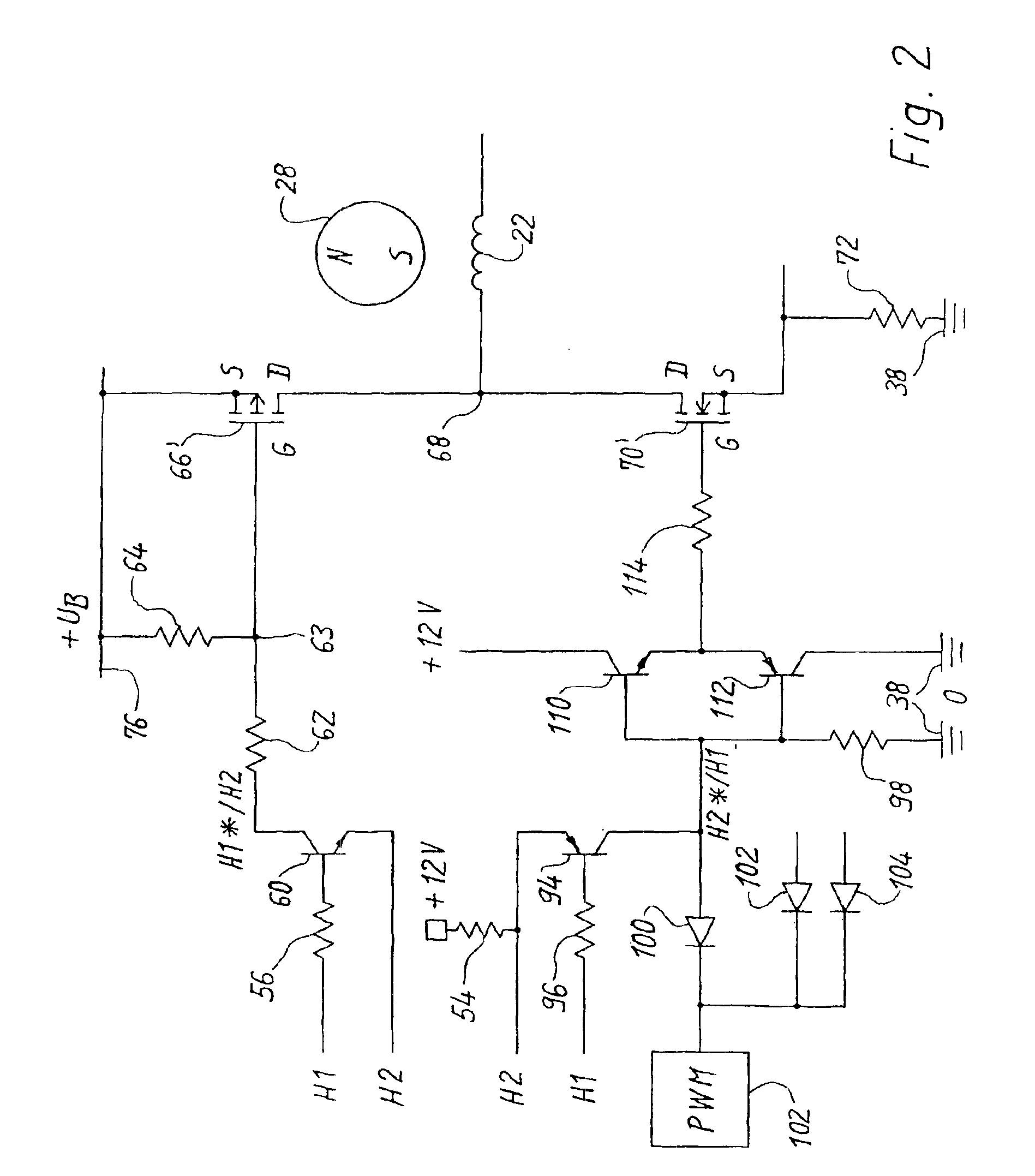

[0017]FIG. 1 shows, at the right, an electronically commutated motor 20 having three stator winding phases 22, 24, 26 and a symbolically indicated permanent-magnet rotor 28, depicted with two poles, around which three rotor position sensors 30, 32, 34 are arranged at intervals of 120° el. and furnish signals H1, H2, H3. These three sensors are also depicted at the far left in FIG. 1. They are connected in series. Lower sensor 34 is connected via a resistor 36 to ground 38, while upper sensor 30 is connected via a resistor 40 to a positive potential, e.g. to a regulated auxiliary voltage of +5 V. Resistors 36 and 40 are usually identical in size. Sensors 30, 32, 34 are normally Hall sensors, but any other sensors would also be possible, e.g. optical sensors.

[0018]The two output signals of Hall sensor 30 are conveyed to the inputs of a comparator 42 whose output 44 (with open collector) is connected via a pull-up resistor 46 to an auxiliary voltage of e.g. +12 V, thus providing at out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com