Heat treatable coated article with reduced color shift at high viewing angles

a coating article and high viewing angle technology, applied in the direction of natural mineral layered products, layered products, chemistry apparatus and processes, etc., can solve the problems of high b* values at the high viewing angle of 45 and 60 degrees, undesirable coloration (i), and significant coloration (e.g., very red or very yellow) at high viewing angles, etc., to achieve efficient and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

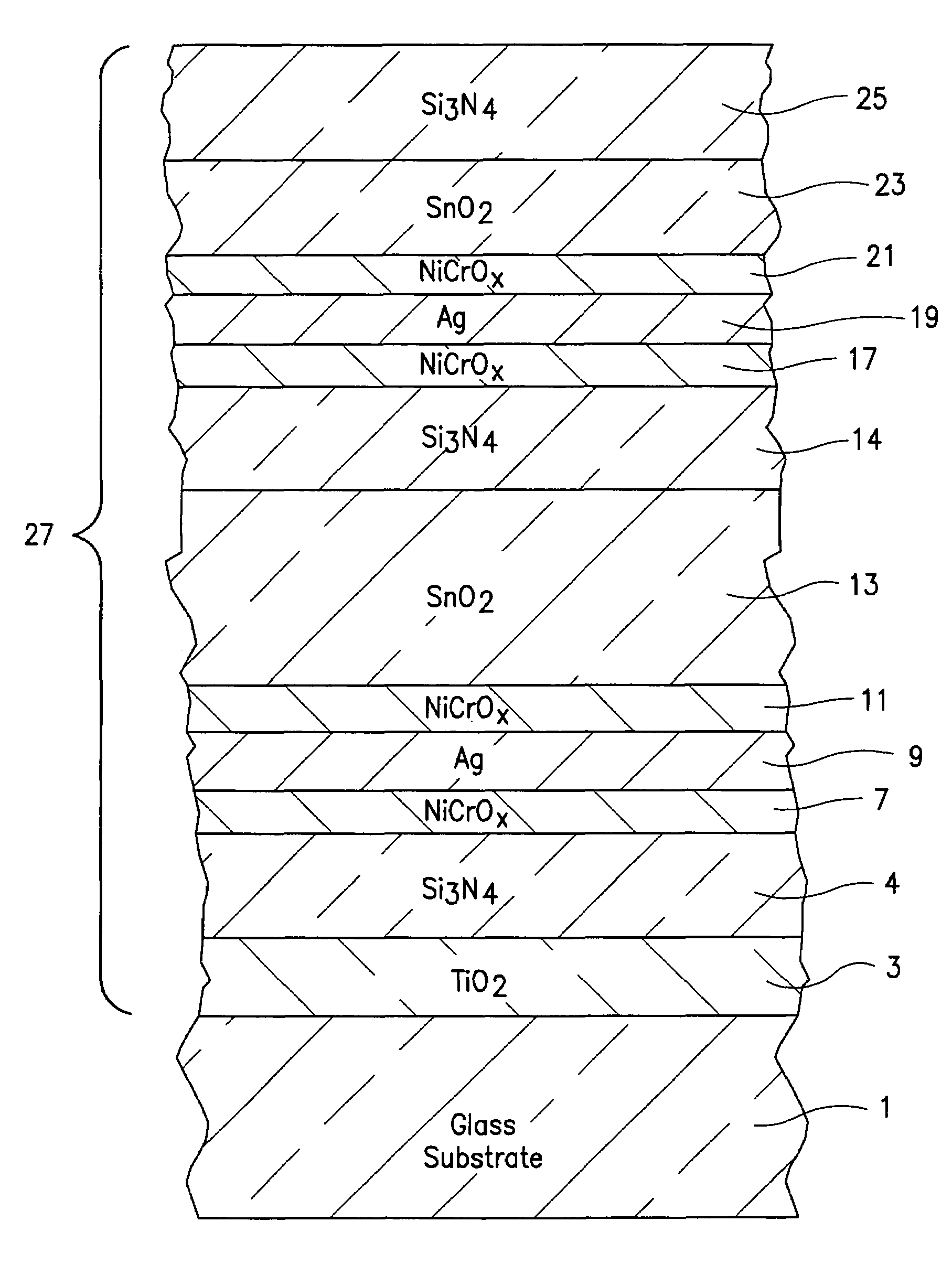

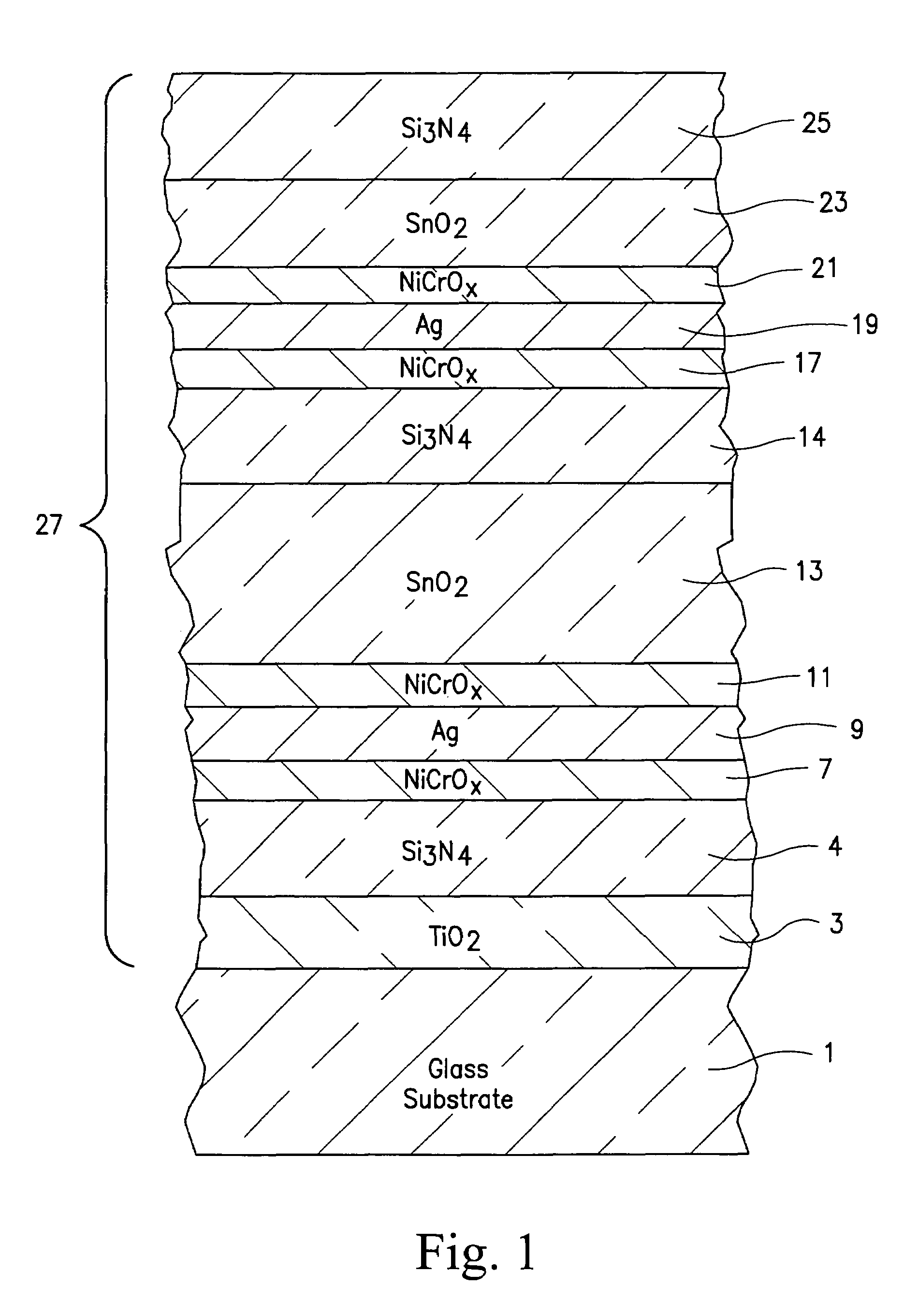

[0049]The following example is provided for purposes of example only, and is not intended to be limiting. Example processing techniques used for sputtering the Example coating may be found in related U.S. Ser. No. 09 / 794,224. The following Example was made via sputtering so as to have approximately the layer stack set forth below, from the glass substrate outwardly. The listed thicknesses are approximations:

[0050]

TABLE 6LAYER STACK FOR EXAMPLE 1LayerThicknessGlass Substrate6mmTiO245ÅSiNx165ÅNiCrOx26ÅAg98ÅNiCrOx26ÅSnO2533ÅSiNx165ÅNiCrOx26ÅAg141ÅNiCrOx26ÅSnO2100ÅSi3N4224Å

[0051]It can be seen that the coating set forth above for this Example includes a titanium oxide layer significantly thinner than that of the comparative coating discussed in the Background. It is believed that this thinner titanium oxide layer is a significant factor in achieving the fairly neutral a* and / or b* values at high viewing angles such as at 60 degrees off-axis. It is also believed that making the upper Ag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sheet resistance | aaaaa | aaaaa |

| SHGC | aaaaa | aaaaa |

| SHGC | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com