Magnetic-pole detecting system for synchronous AC motor and magnetic-pole detecting method therefor

a synchronous ac motor and magnetic-pole detection technology, applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problem of complex magnetic-pole detection system, and achieve the effect of damping the oscillation of the moving element and shortening the distance that the moving element travels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

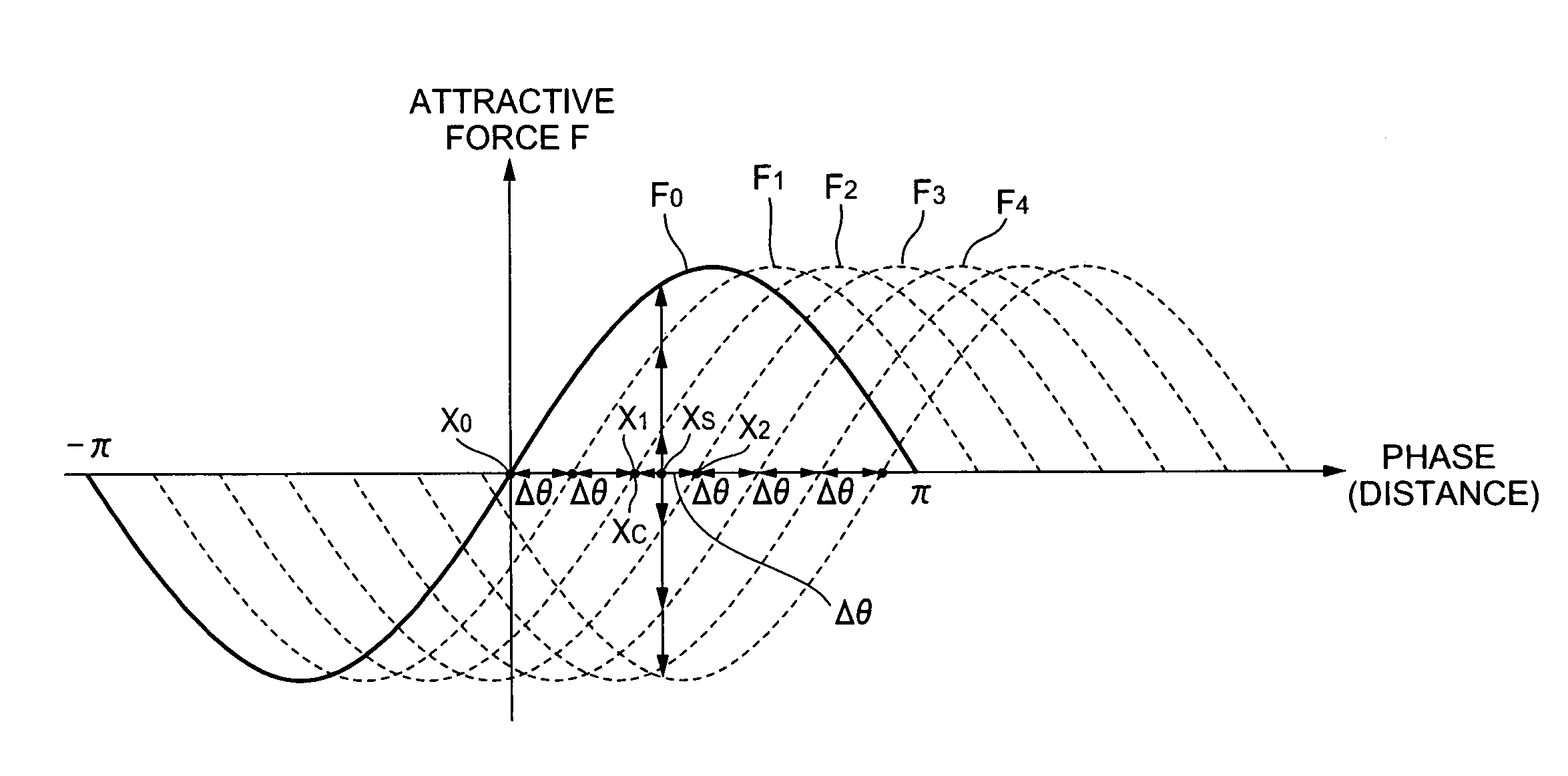

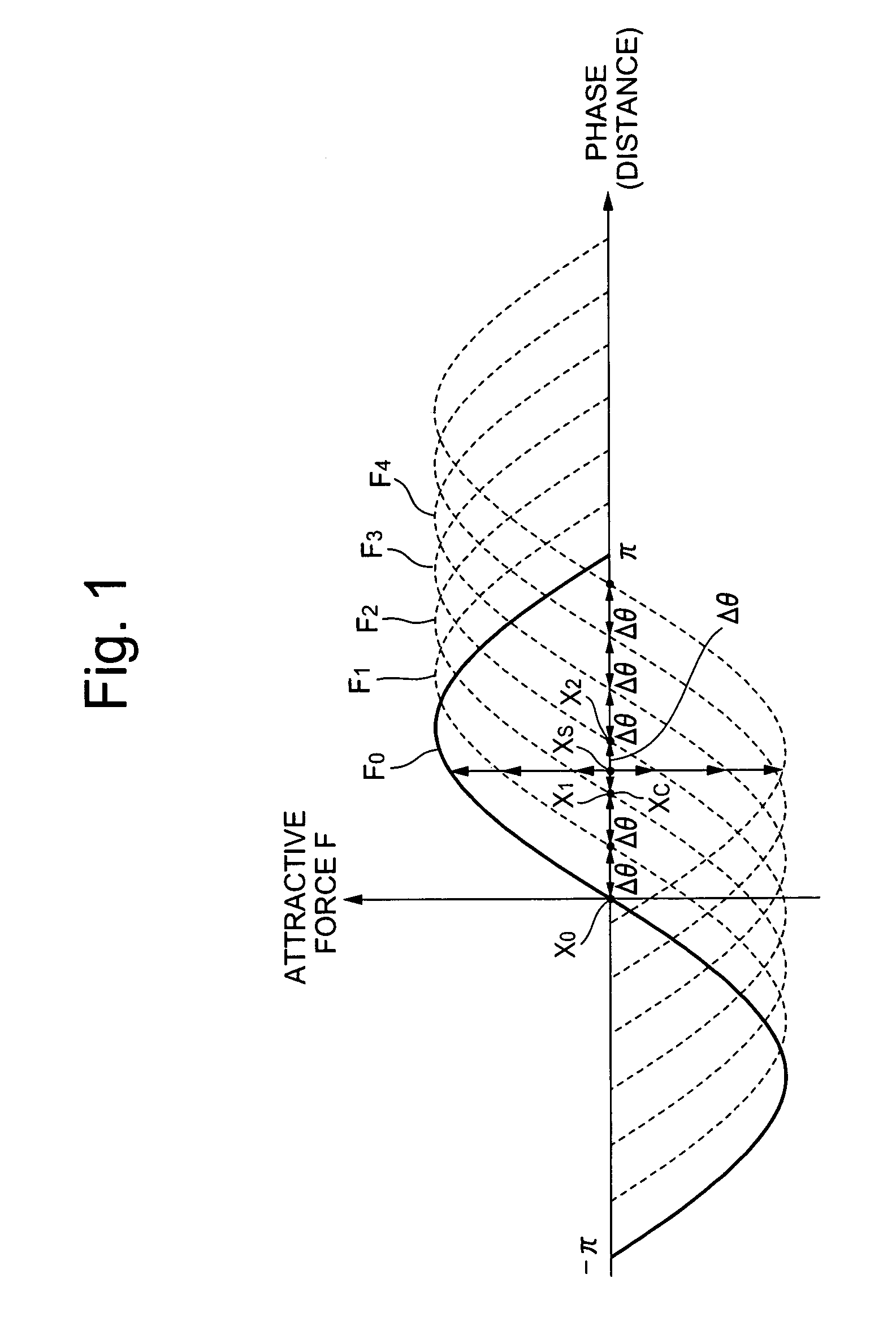

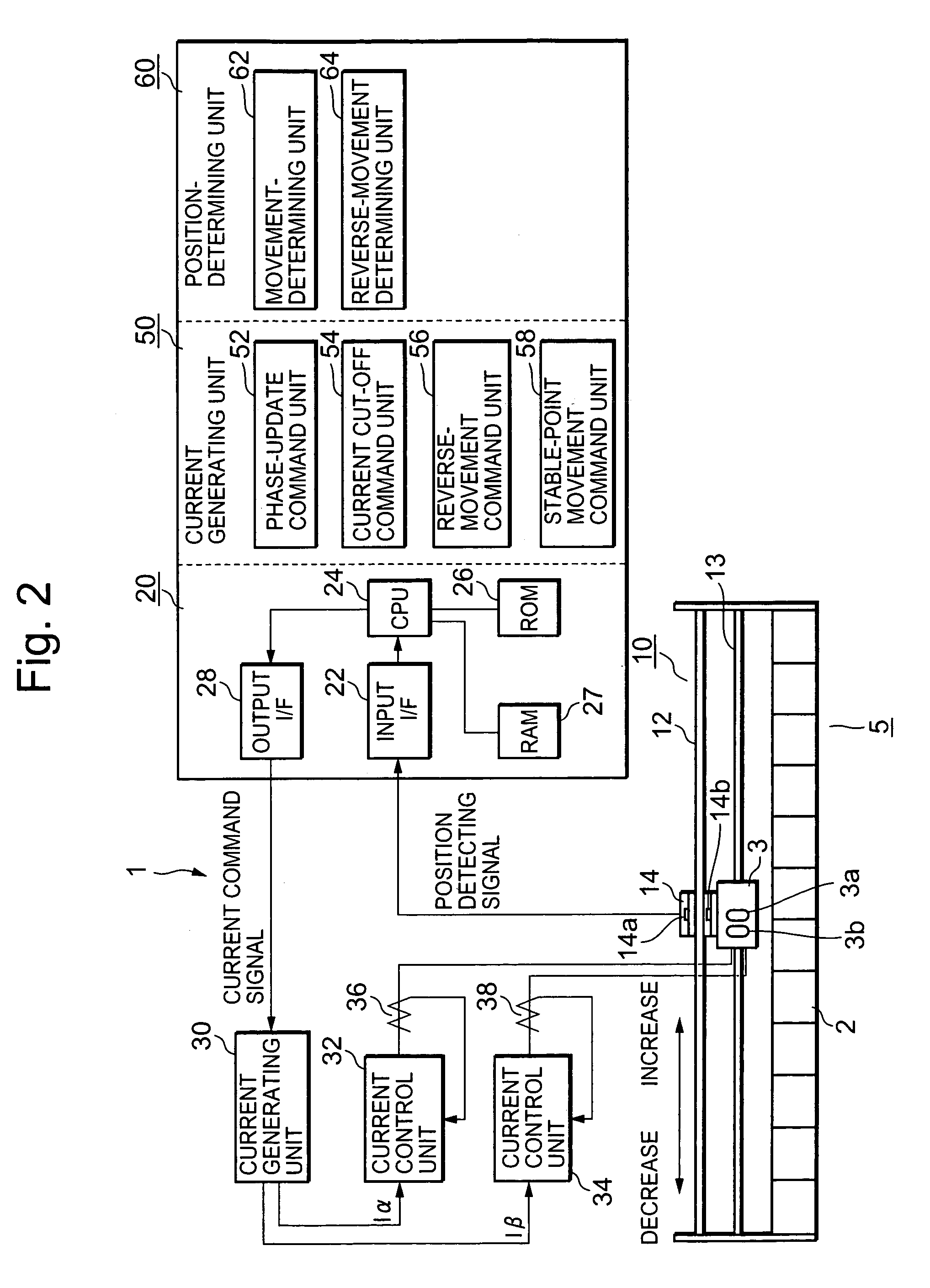

[0065]An embodiment of the present invention that implements the foregoing position-detecting principle for a moving element is set forth referring to FIG. 2. FIG. 2 is an overall block diagram of a magnetic-pole detecting system in a synchronous AC motor.

[0066]In FIG. 2, a magnetic-pole detecting system 1 is equipped with a 2-phase, linear synchronous AC motor 5 (referred to as an AC motor, hereinafter) that has a stator 2 and comprises a moving element 3 with an α-phase coil 3a and a β-phase coil 3b, each phase coil being arranged facing, and having a predetermined gap with, the stator 2; a position detector 10 that detects the position of the moving element 3; a microcomputer 20 that generates an electric current command signal for making currents flow in the AC motor 5 and that executes predetermined processes based on position-detecting signals from the position detector 10; a current generating unit 30 that is connected to the output of microcomputer 20 and, based on the curre...

embodiment 2

[0094]Another embodiment of the present invention will be described, mainly according to FIG. 4. The foregoing embodiment was described ignoring the influence of cogging torque that originates in the AC motor 5; however, in fact, sinusoidal cogging torque Tc occurs as shown in FIG. 4. Therefore, in the present embodiment, a highly accurate magnetic-pole detecting system that is unsusceptible to the cogging torque Tc is set forth.

[0095]It is known that the maximal value of the sinusoidal cogging torque Tc occurs m times over a range of 2Π in terms of electrical angle of the moving element 3, wherein m is the least-common multiple of the number of slots in the stator 2 and double the number of pole-pairs Pt.

[0096]In this situation, for example, if the stator 2 has 12 slots and 8 poles, this least common multiple m is 24; therefore, positive or negative peak values of the cogging torque Tc occur every 15 degrees, and the cogging torque Tc becomes zero every 7.5 degrees as given by elec...

embodiment 3

[0099]Embodiments 1 and 2 above described the detection of positions of the moving element 3, ignoring the influence of friction. However, in reality, since friction exists when the moving element 3 moves, the stable point of the moving element 3 differs from its standstill position. In order to reduce the influence of this type of friction, a means is available for increasing the currents flowing in the coils 3a and 3b of the moving element 3 so that the attractive force of the moving element 3 is increased, but such a means is not appropriate since, when the currents flowing are increased, the rated current of semiconductor devices forming the current generating unit 30 increases.

[0100]Therefore, a magnetic-pole detecting system is set forth according to FIG. 5, wherein the accuracy of detecting the magnetic-pole positions of the moving element 3 is raised without increasing the currents that flow in the coils 3a and 3b. FIG. 5 is a characteristic curve chart representing the attr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com