Alternating current driven type plasma display device and production method therefor

a technology of alternating current and display device, which is applied in the manufacture of electrode systems, cold cathode manufacturing, and electric discharge tube/lamp manufacture, etc., can solve the problems of increasing driving voltage, increasing driving voltage, increasing driving voltage, etc., and achieves enhanced discharge stability, time delay of discharge, and enhanced reliability of alternating current driven type plasma display device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0064]Example 1 relates to an alternating current driven type plasma display device according to the present invention (hereinafter, referred to also as “plasma display device” for short) and a production method therefor.

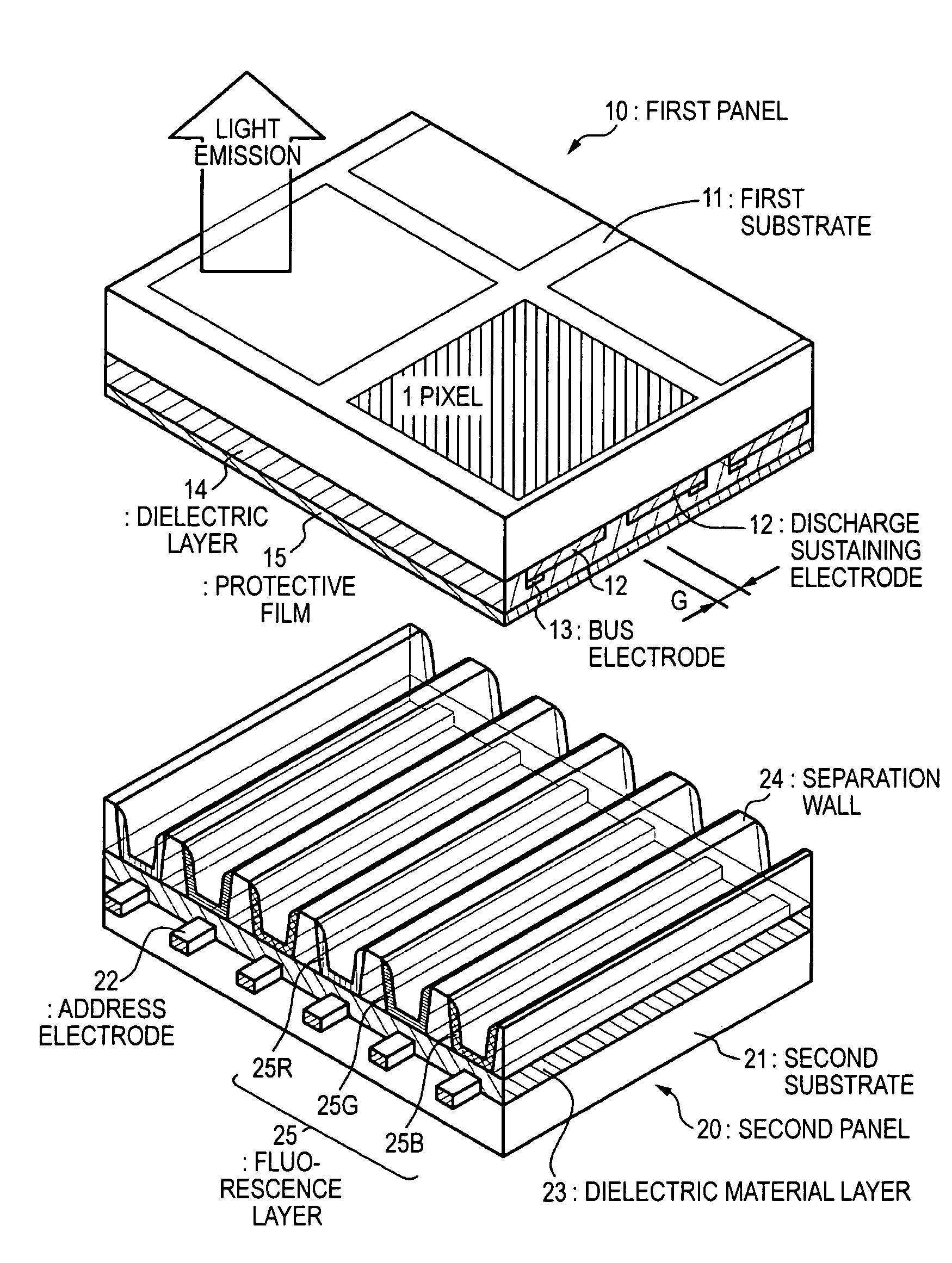

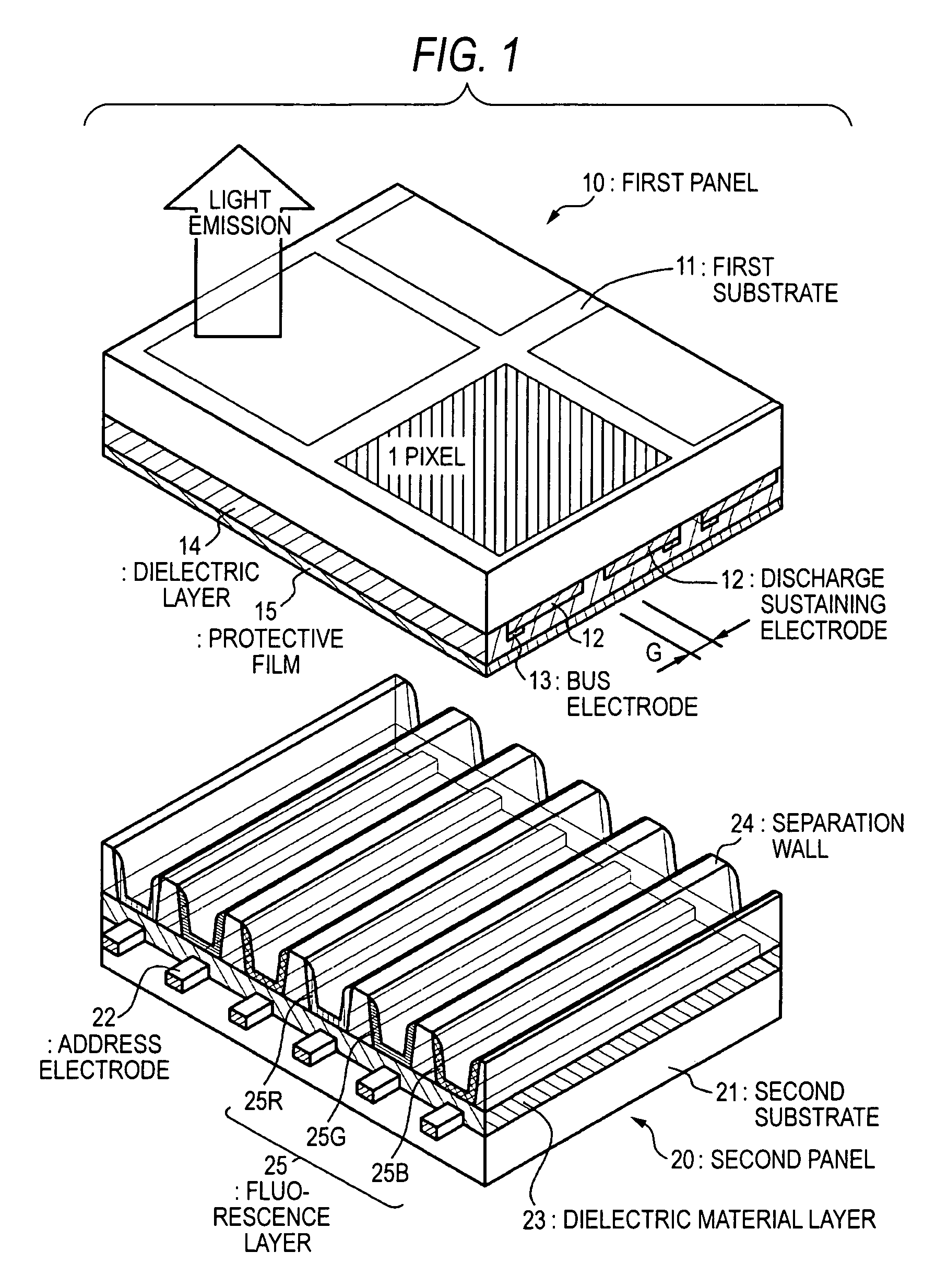

[0065]The plasma display device of Example 1, being a plasma display device of tri-electrode type, comprises a first panel 10 comprising a plurality of first electrodes 12 formed on a first substrate 11 and a dielectric layer 14 formed on the first substrate 11 and the first electrodes 12 and a second panel 20, in which the first panel 10 and the second panel 20 are bonded to each other in circumferential portions thereof. On this occasion, a schematic exploded perspective view of the plasma display device of Example 1 is same as that shown in FIG. 1. Since constitution and structure of this plasma display device are same as those of the plasma display device as described in “BACKGROUND OF THE INVENTION”, detailed description is omitted. Hereinafter, difference from...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap