Droplet discharging device and method of detecting discharge abnormality thereof

a technology of droplet discharge and abnormal discharge, which is applied in the direction of printing, other printing apparatuses, etc., can solve the problems of inability to discharge droplets, image quality deterioration, etc., and achieve the effect of simple structure, accurate detection of residual vibration of vibrating plate, and enhanced precision in the detection of discharge abnormalities of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

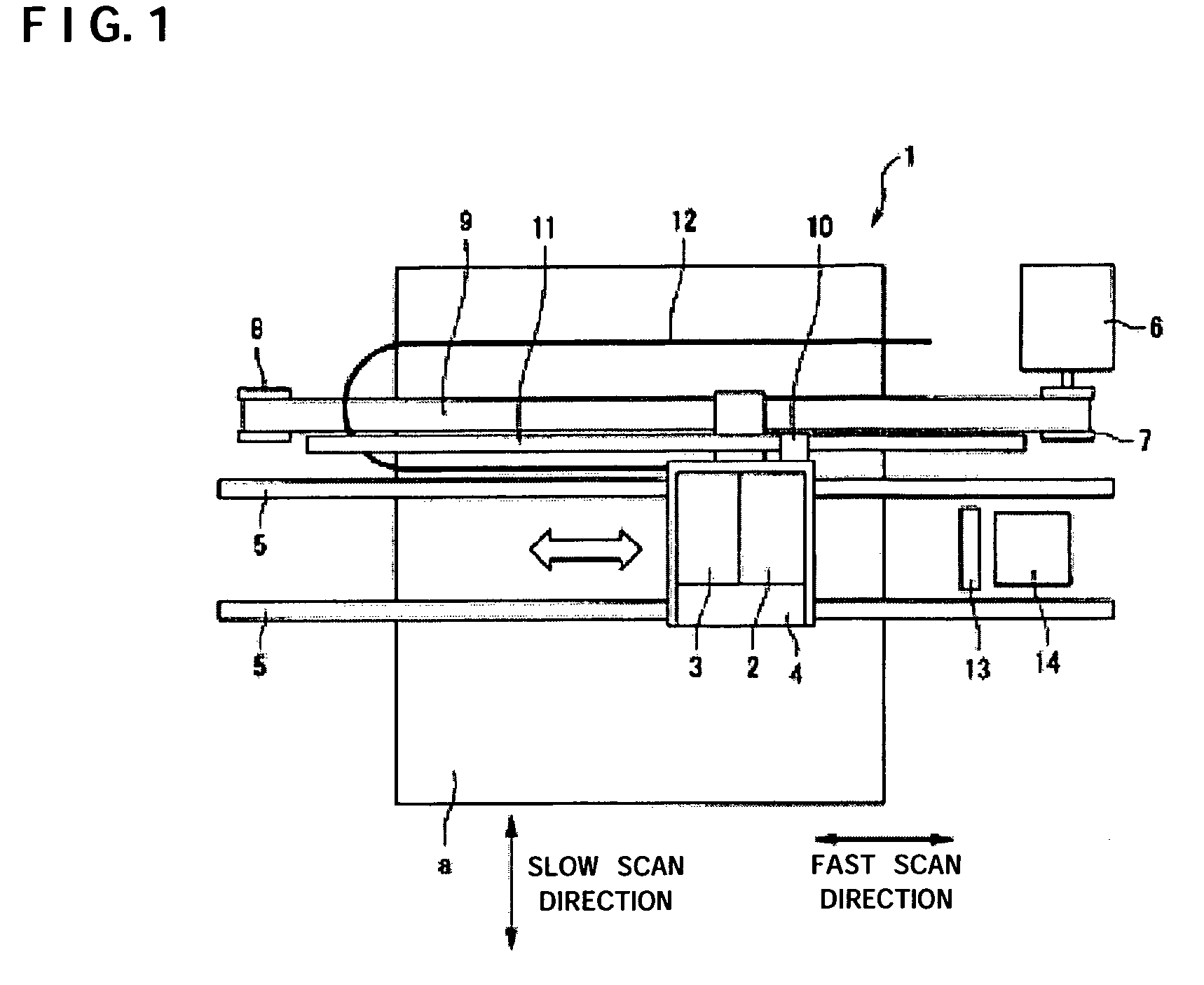

[0044]FIG. 1 is a plan view showing the schematic structure of an inkjet printer 1 to be one of droplet discharging devices according to a first embodiment of the invention.

[0045]The inkjet printer 1 comprises a carriage 4 mounting a head unit 2 and an ink cartridge 3 thereon as shown in FIG. 1, and the carriage 4 can be guided by a pair of carriage shafts 5 and can be thus moved in a fast scan direction. Moreover, a part of the carriage 4 is fixed to a toothed belt 9, and the toothed belt 9 is laid between a driving pulley 7 and a driven pulley 8 which are fixed to the rotating shaft of a motor 6.

[0046]Furthermore, an encoder 10 is attached to the carriage 4 and a linear scale 11 is provided in the direction of movement of the carriage 4. Consequently, the position of the head unit 2 on the carriage 4 is detected by the encoder 10.

[0047]In FIG. 1, 12 denotes a cable for electrically connecting the head unit 2 and a system controller. 13 denotes a wiper for cleaning the surface of a...

second embodiment

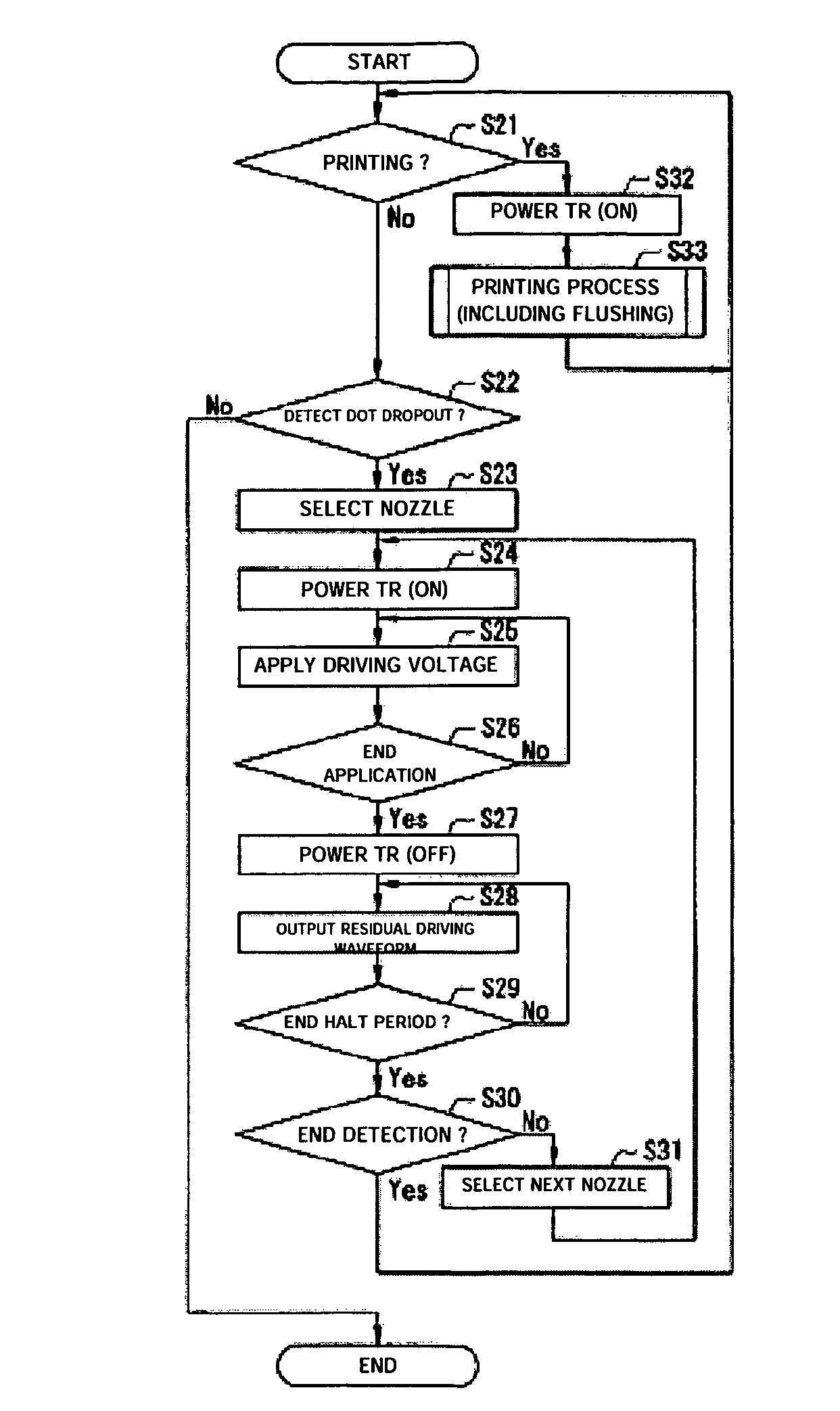

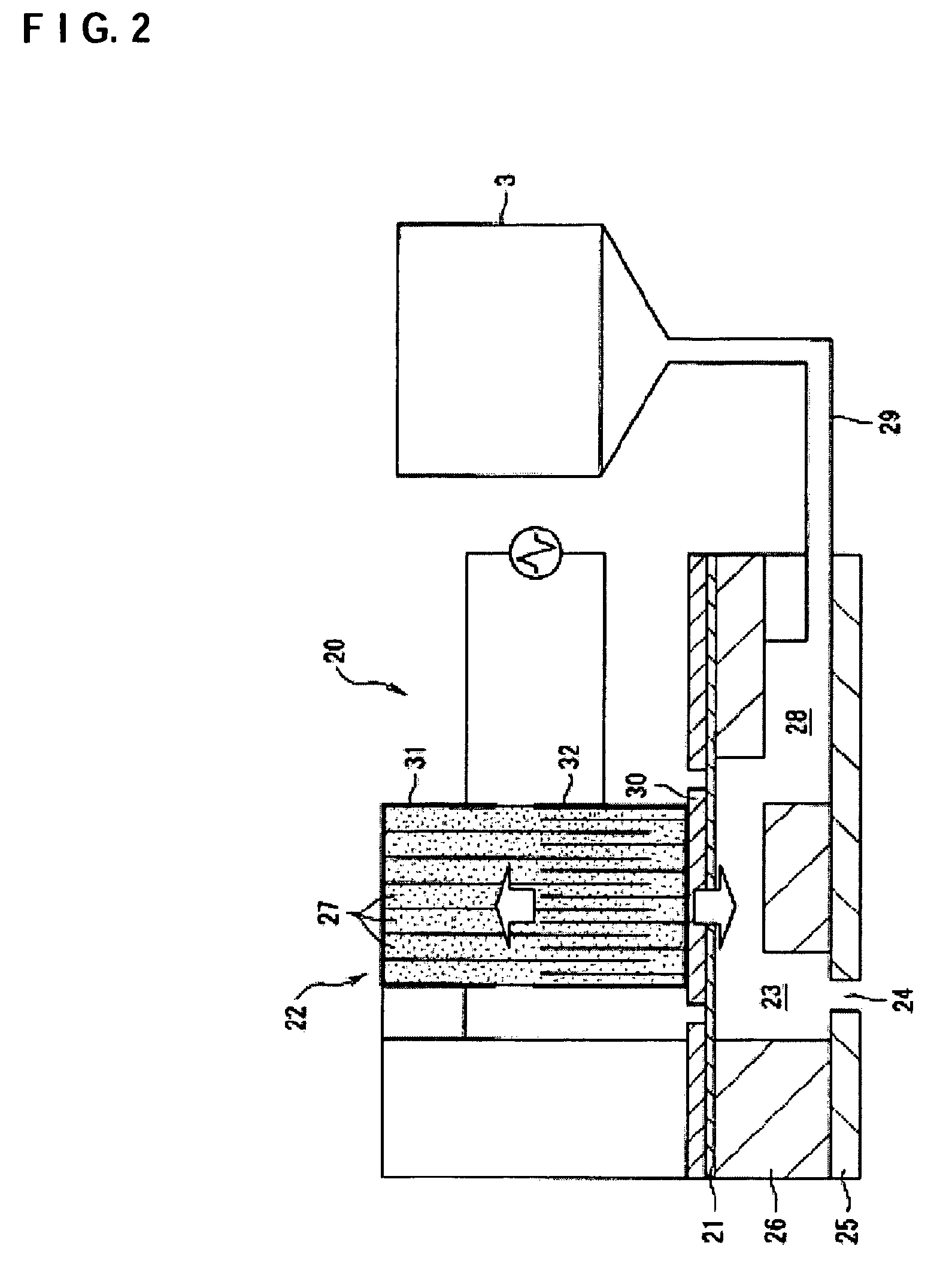

[0122]Referring to FIGS. 2 and 13, next, description will be given to a second embodiment of the invention in which the detection of a residual vibration is carried out when the discharge abnormality of each nozzle of each inkjet head 20 (the dot dropouts of the nozzle) is to be detected based on the detection principle of the residual vibration described above.

[0123]In the second embodiment, as shown in FIG. 13, there are provided at least a plurality of piezoelectric actuators 22a to 22e, a driving circuit 41 to be a driving unit, a nozzle selecting portion 42 to be a nozzle selecting unit, a residual vibration detecting circuit 43 to be a residual vibration detecting unit, a transistor 47 to be a switch unit, and a control circuit 48 to be a switch control unit.

[0124]More specifically, a structure according to the second embodiment has common components to the structure according to the first embodiment shown in FIG. 8, and is different in that the transistor 44 and the switch 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com