Bidirectional optical assembly and method for manufacturing the same

a technology of bidirectional optical assembly and manufacturing method, which is applied in the direction of optical elements, multiplex communication, instruments, etc., can solve the problems of difficult miniaturization of optical assembly types and relatively uneconomical costs, and achieve the effect of superior optical coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

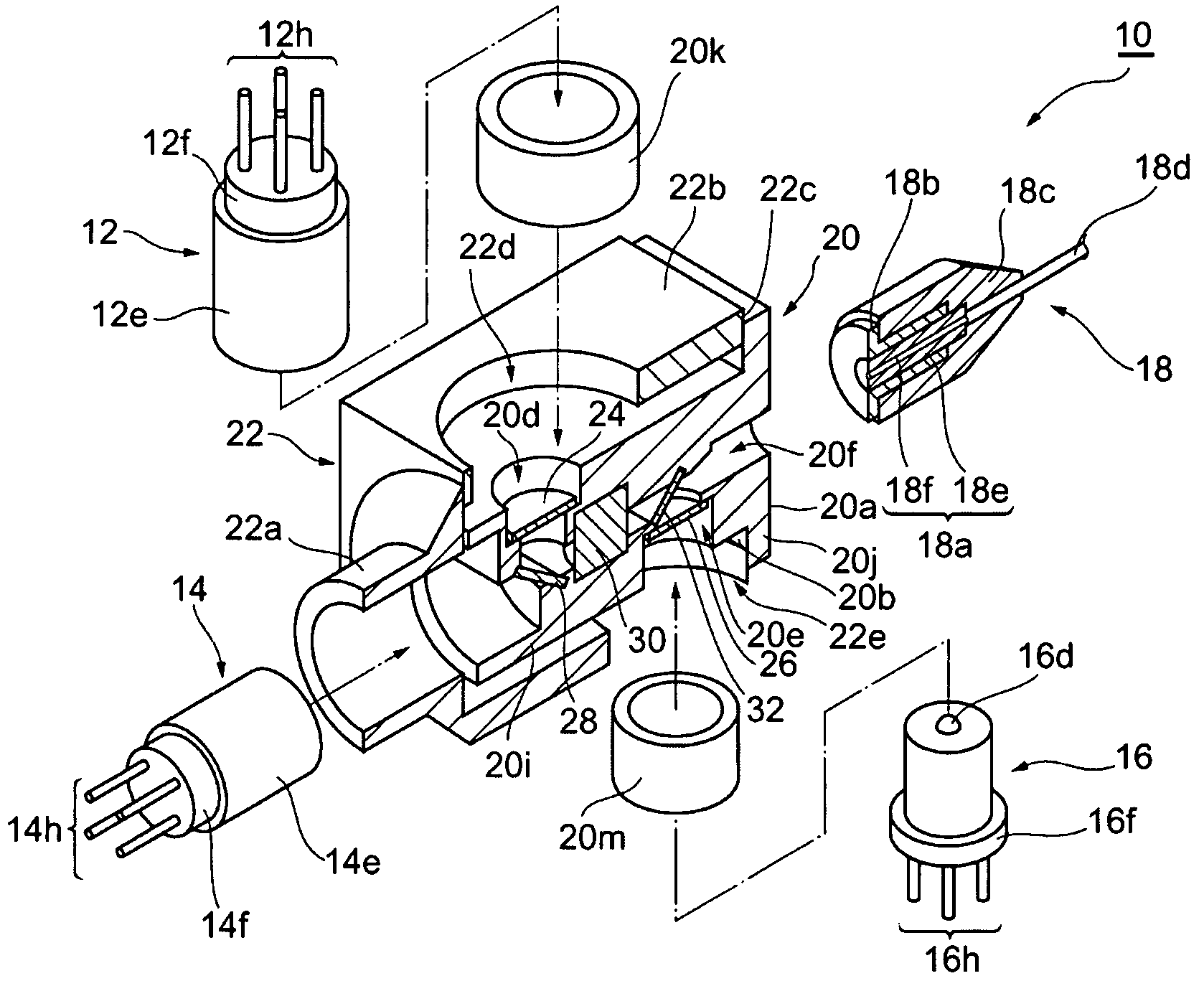

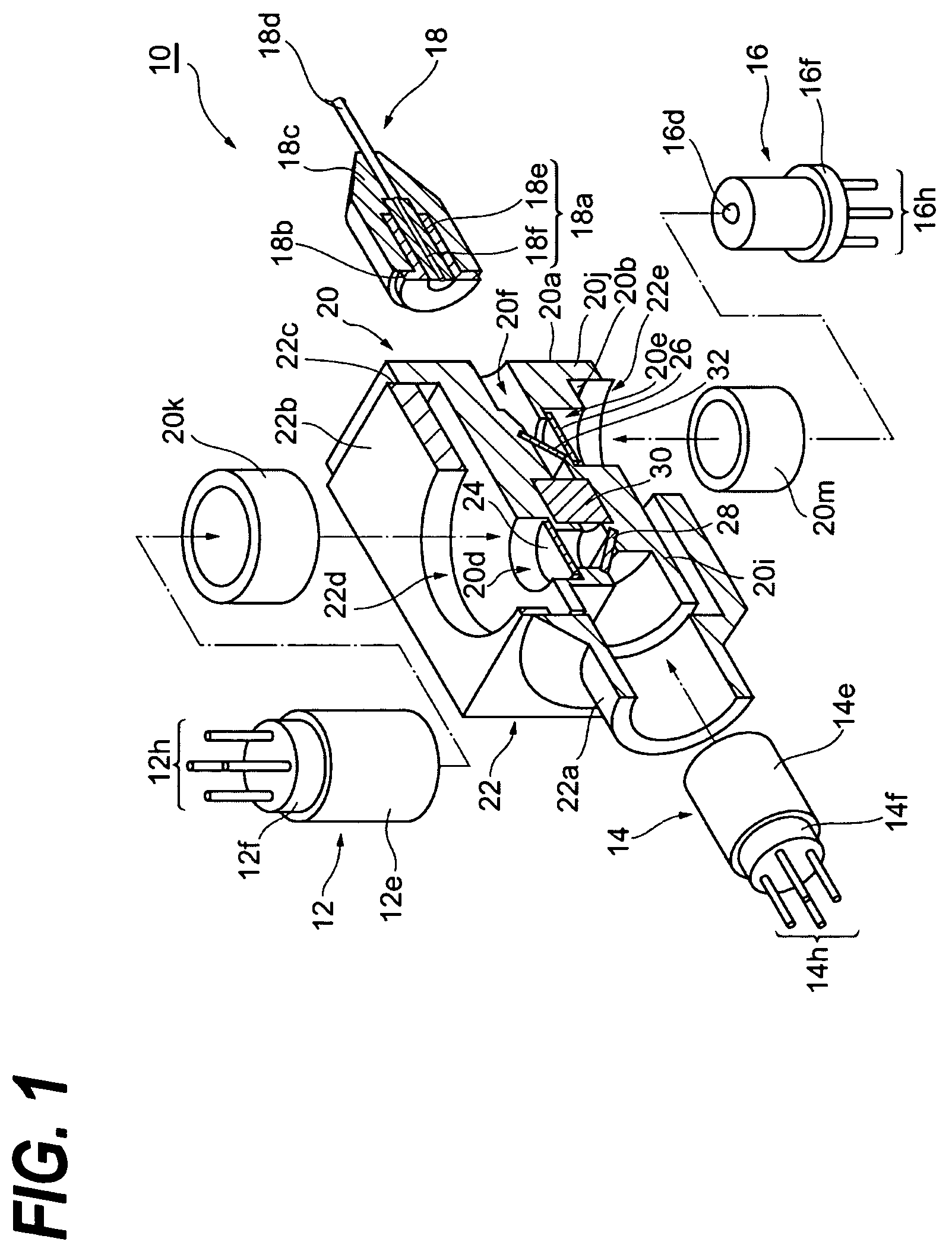

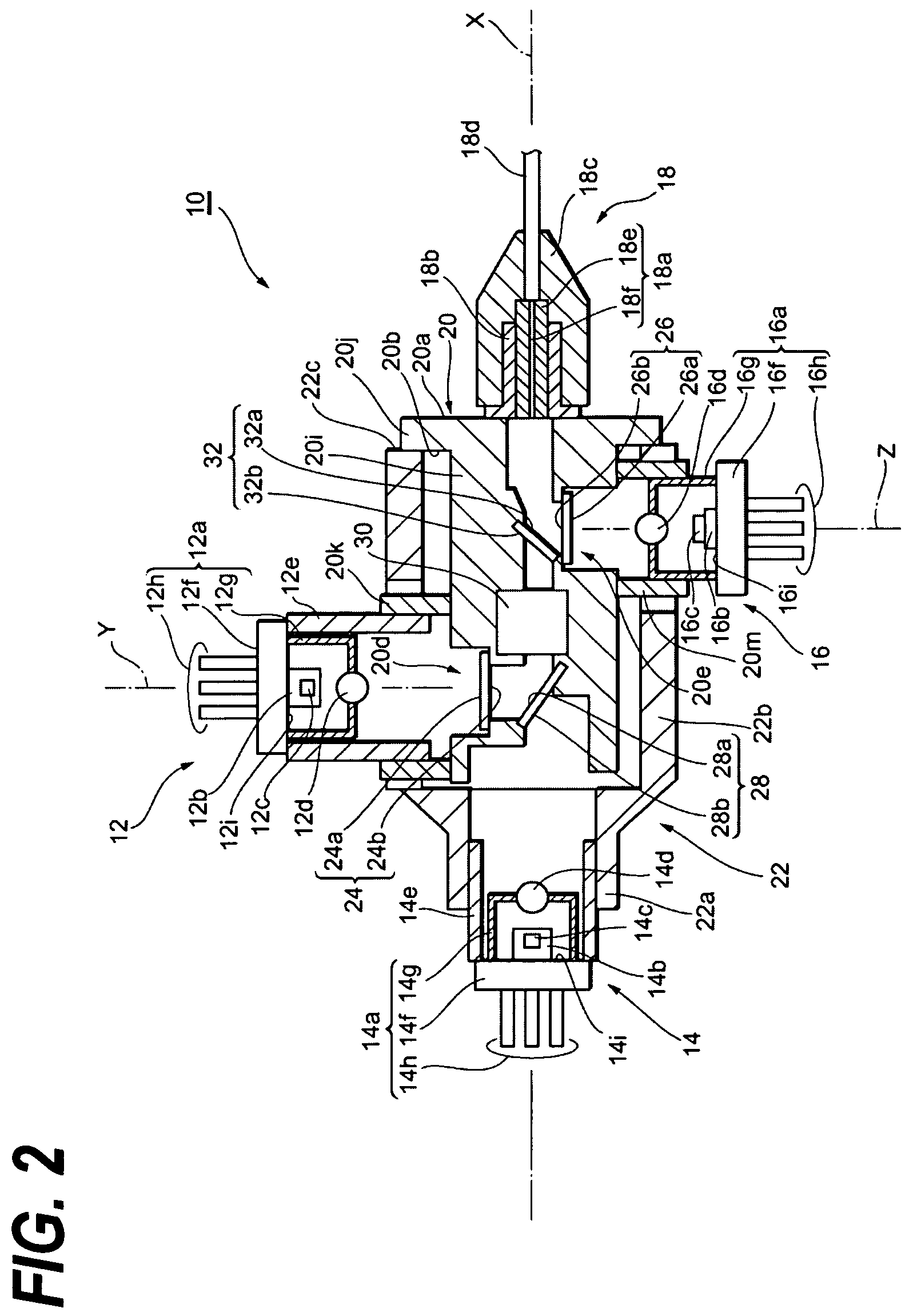

[0021]FIG. 1 is an exploded perspective view showing a bidirectional optical assembly according to the first embodiment of the present invention, which is partially broken. FIG. 2 is a cross sectional view of the bidirectional optical assembly according to the first embodiment. The bidirectional optical assembly 10 shown in FIGS. 1 and 2 comprises a first transmitting optical subassembly (TOSA) 12, a second TOSA 14, a receiving optical subassembly (ROSA) 16, a sleeve assembly 18, an inner housing 20 and an outer housing 22.

[0022]The first TOSA 12 comprises a package 12a, a sub-mount 12b, a light-emitting device 12c, a condenser lens 12d, and a sleeve 12e. The package 12a includes a stem 12f, a lens cap 12g, and a lead terminal 12h. The stem 12f provides a mounting surface 12i. A plurality of lead terminals 12h extend from the stem 12g to a direction substantially perpendicular to the stem 12f. On the mounting surface 12i is installed with the sub-mount 12b, and on the sub-mount 12b ...

second embodiment

[0045]FIG. 3 is a cross sectional view of the second embodiment of the bi-directional optical assembly according to the present invention. Next, regarding the bi-directional optical assembly 10b shown in FIG. 3, configurations different from those of the bi-directional optical assembly 10 already described will be described.

[0046]In the bi-directional optical assembly lOb, the ROSA 16 further provides the sleeve 16j. This sleeve 16h has a tubular shape with one end thereof being secured by the mounting surface 16i, while, the other end thereof facing the end of the second alignment member 20m. The inner diameter of the second alignment member 20m is slightly greater than the outer diameter of the lens cap 16g.

[0047]According to this bi-directional optical assembly, the ROSA 16 may adjust the position along two directions each intersecting the axis Z by sliding the end surface of the sleeve 16j on the end surface of the second alignment member 20m. Accordingly, the optical coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com