Method for operating an internal combustion engine, taking into consideration the individual properties of the injection devices

a technology of injection device and internal combustion engine, which is applied in the direction of electrical control, process and machine control, instruments, etc., can solve the problems of inaccurate ascertaining of actual operation methods, and achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

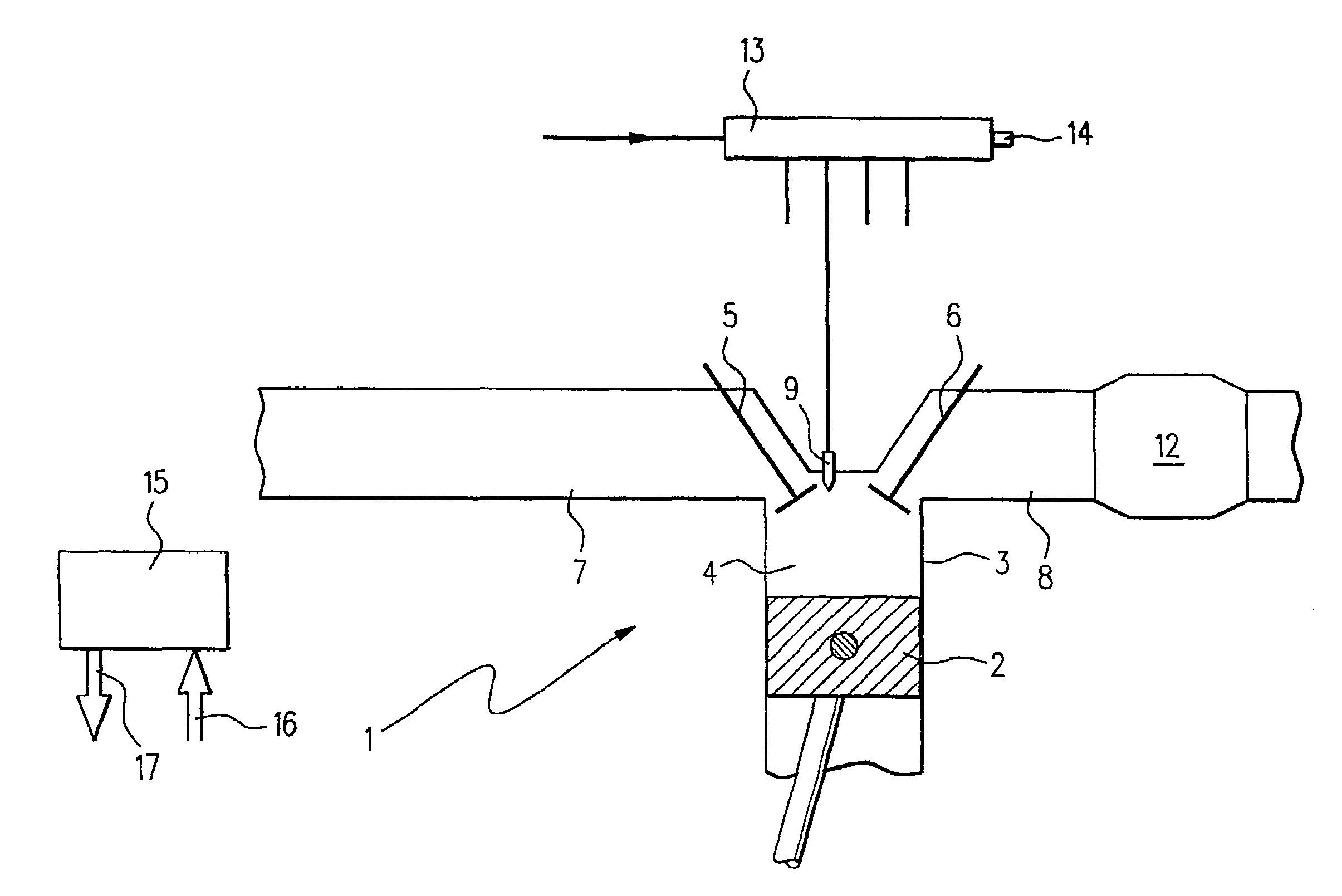

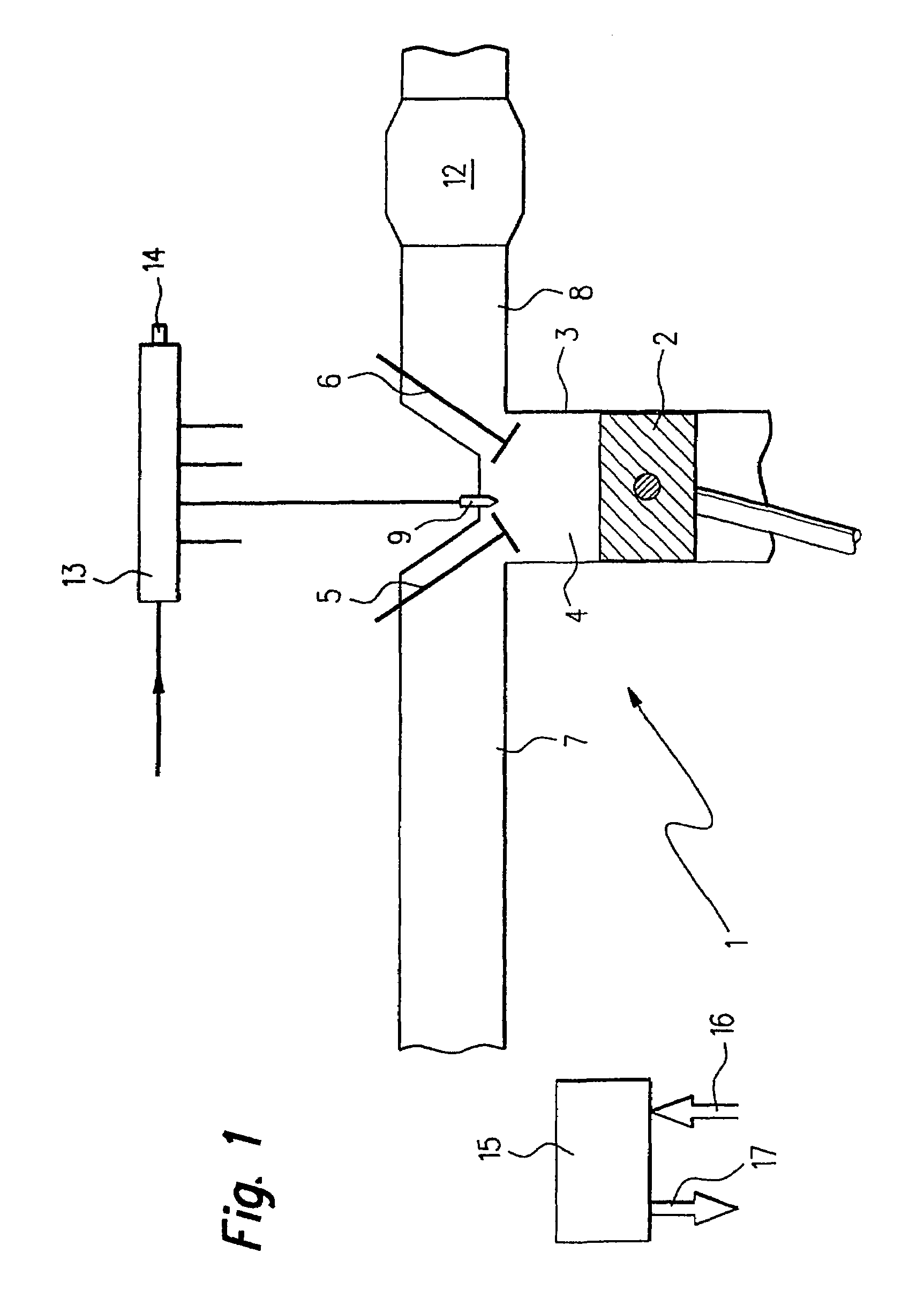

[0023]An internal combustion engine 1 of a motor vehicle, in which a piston 2 is movable back and forth in a cylinder 3, is illustrated in FIG. 1. Cylinder 3 is provided with a combustion chamber 4 which is delimited, inter alia, by piston 2, an inlet valve 5, and an outlet valve 6. An intake pipe 7 is coupled to inlet valve 5 and an exhaust pipe 8 is coupled to outlet valve 6.

[0024]A fuel injector 9 projects into combustion chamber 4 in the area of inlet valve 5 and outlet valve 6, via which fuel may be injected into combustion chamber 4. A catalytic converter 12, which is used for purifying the exhaust gases resulting due to the combustion of the fuel, is housed in exhaust pipe 8.

[0025]Fuel injector 9 is connected to a fuel accumulator 13 via a pressure line. In a similar way, the fuel injectors of the other cylinders of internal combustion engine 1 are also connected to fuel accumulator 13. Fuel accumulator 13 is supplied with fuel via a supply line. A mechanical fuel pump may be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com