Toy vehicle track

a technology for vehicles and tracks, applied in the field of toys, can solve the problems of track or rails ripping or tearing, track to crease permanently, track or rails unable to be coiled upon themselves for transportation or storage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

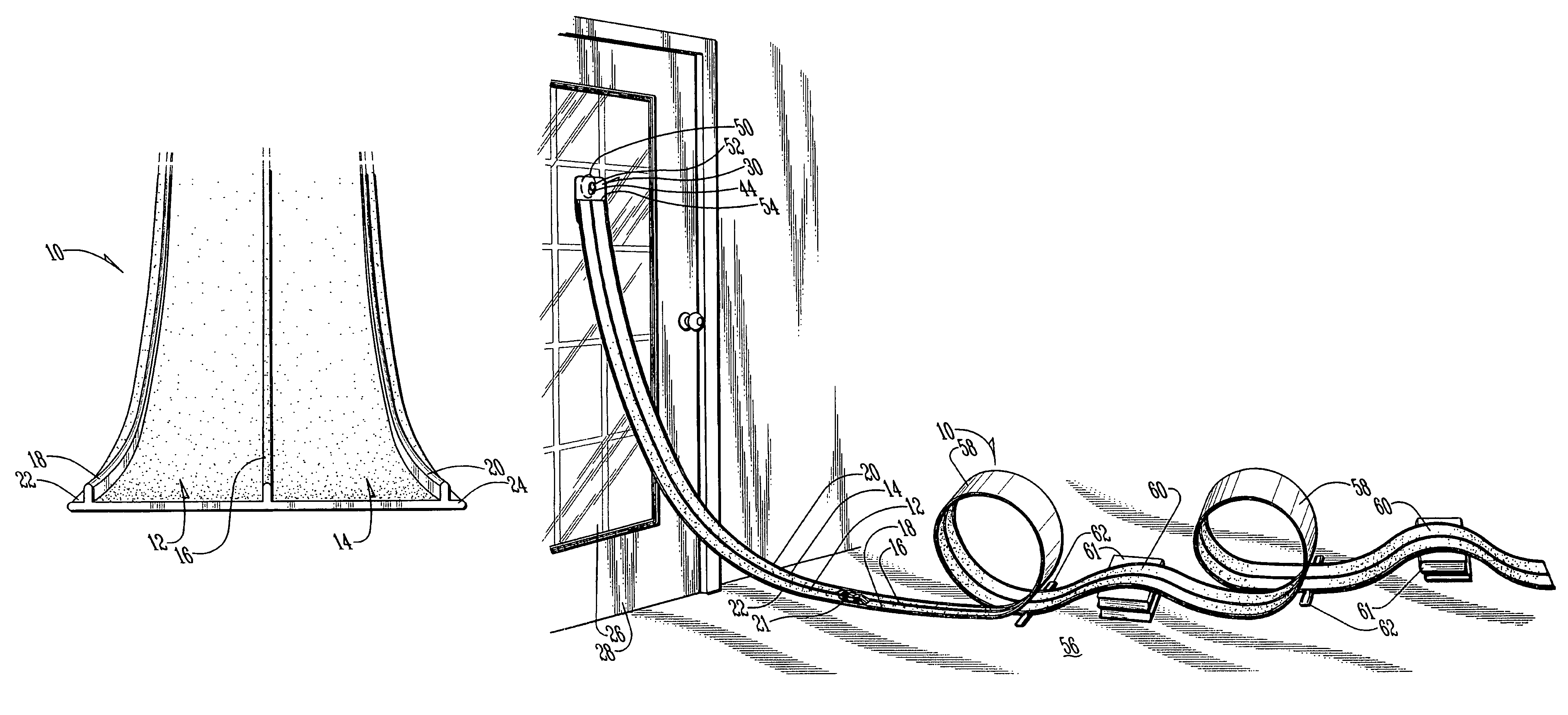

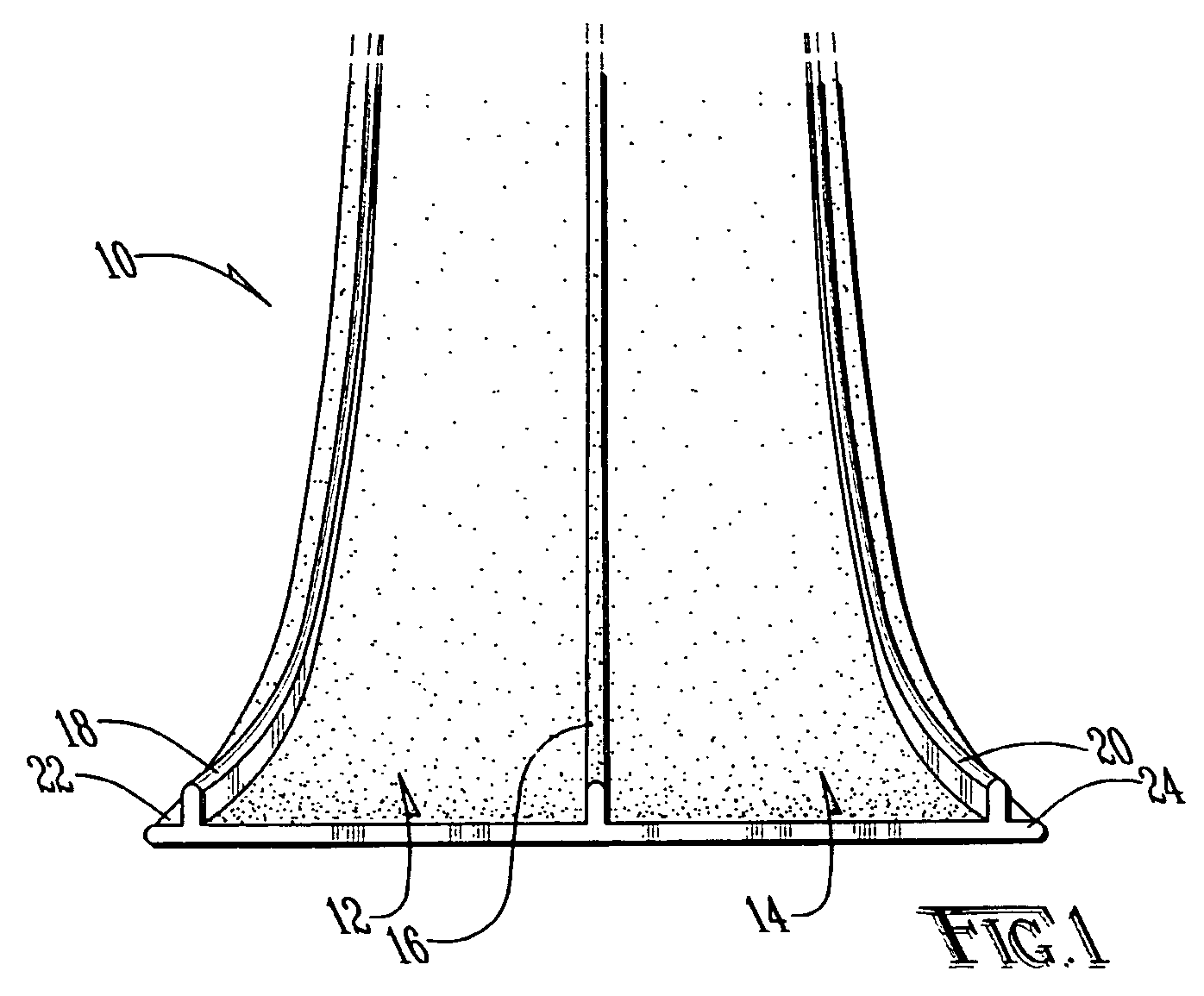

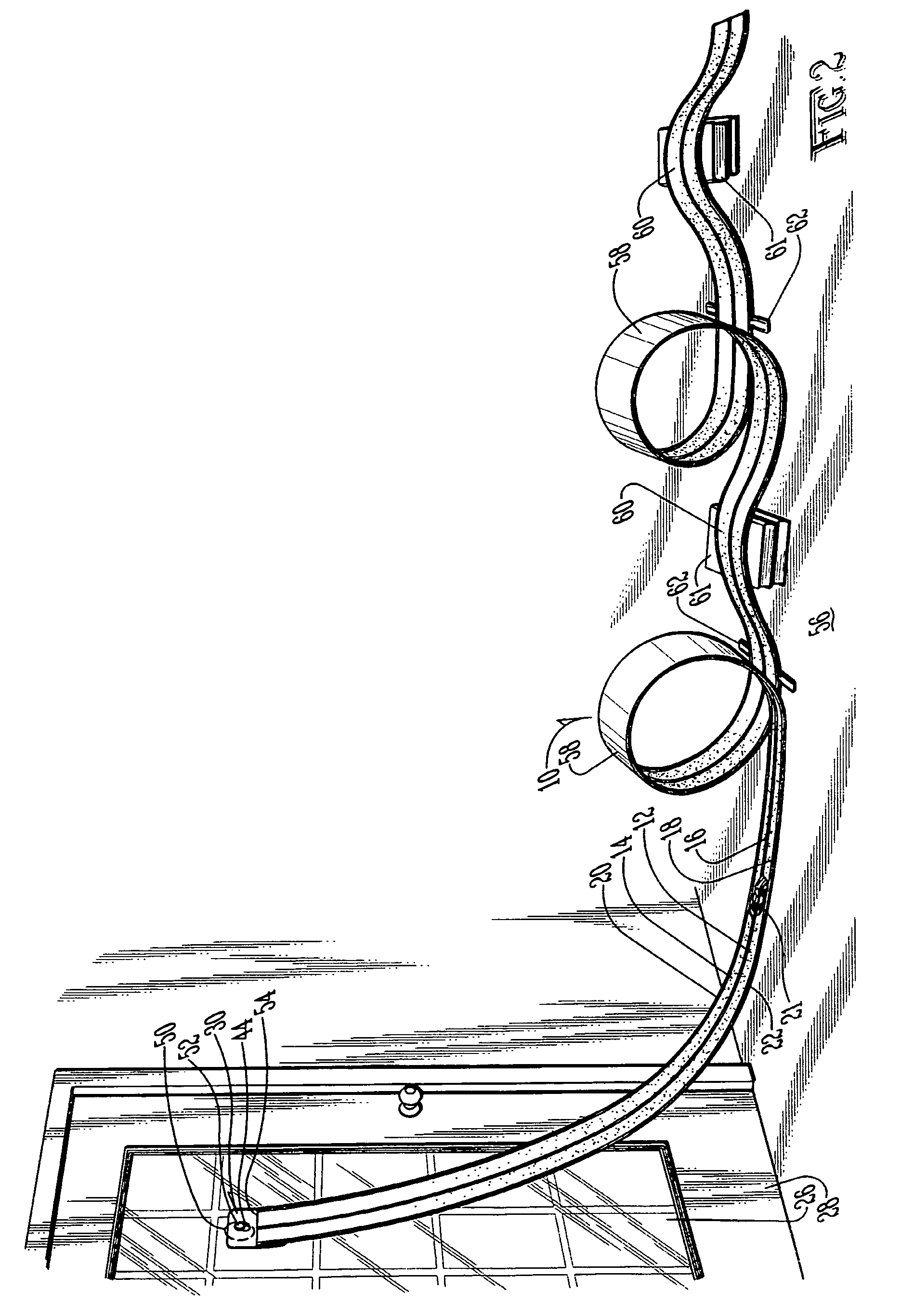

[0033]A toy vehicle track is shown generally as (10) in FIG. 1. The track (10) is preferably formed of colored, extruded polyvinylchloride. As shown in FIG. 1, the track (10) includes a left track surface (12) and a right track surface (14), separated by a center rail (16). The left track surface (12) and right track surface (14) are bordered by a left rail (18) and a right rail (20), respectively. Extending laterally from, and integral with, the left track surface (12) is a left rib (22), and extending laterally from, and integral with, the right track surface (14) is a right rib (24). Although the track (10) may be constructed of any suitable dimensions or configurations, in the preferred embodiment, the left track surface (12) and right track surface (14) are each preferably between 0.5 and 20 centimeters wide, and between 0.5 and 100 millimeters thick, more preferably, between 2 and 6 centimeters wide and between 1 and 2 millimeters thick, and most preferably, about 4.3 centimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com