Connection and junction box for a solar module

a solar module and junction box technology, applied in the direction of coupling device connection, coupling device details, contact members penetrating/cutting insulation/cable strands, etc., can solve the problems of reducing the power of solar modules in series connection, difficult contact, and even damage, etc., to achieve the effect of convenient, fast and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

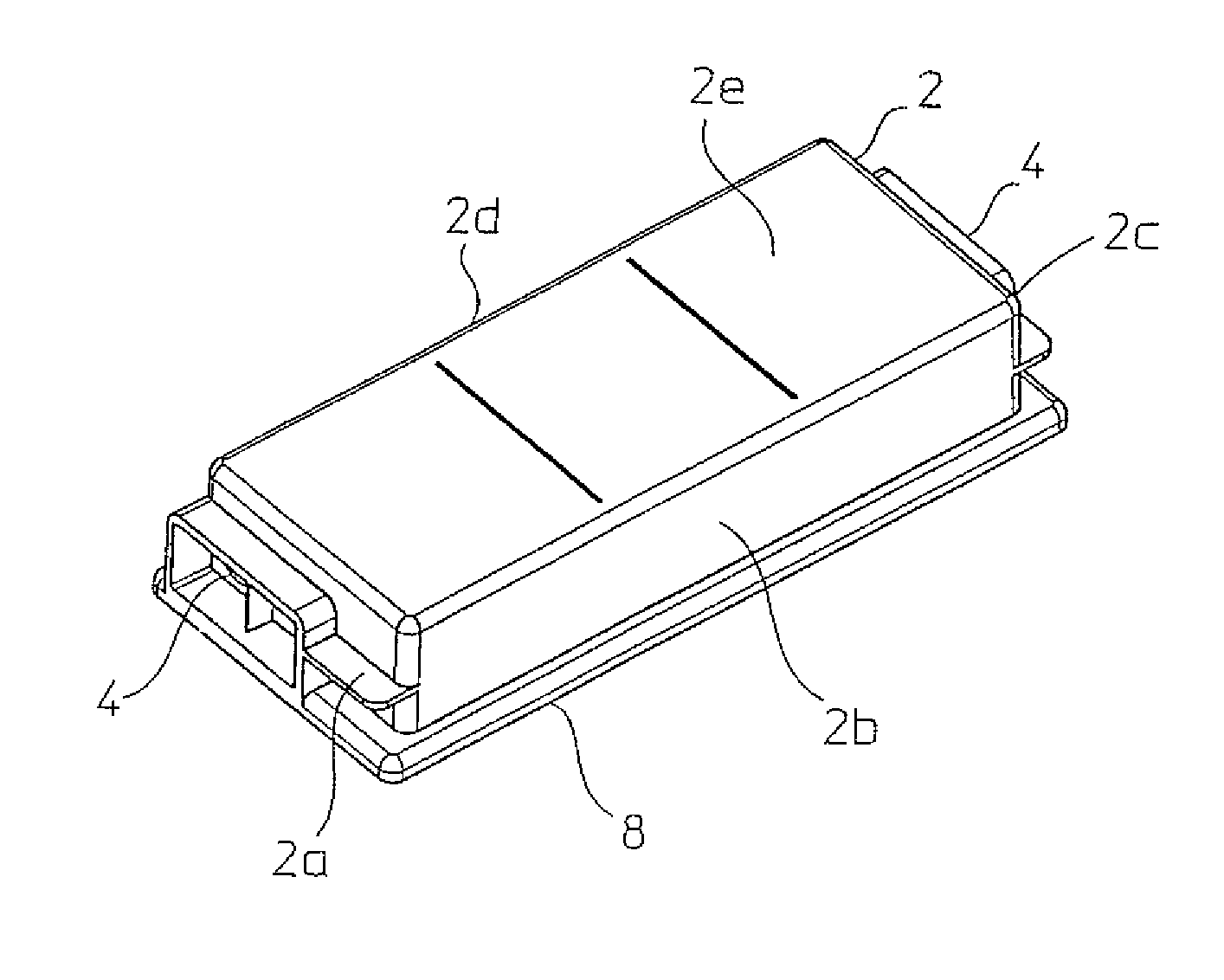

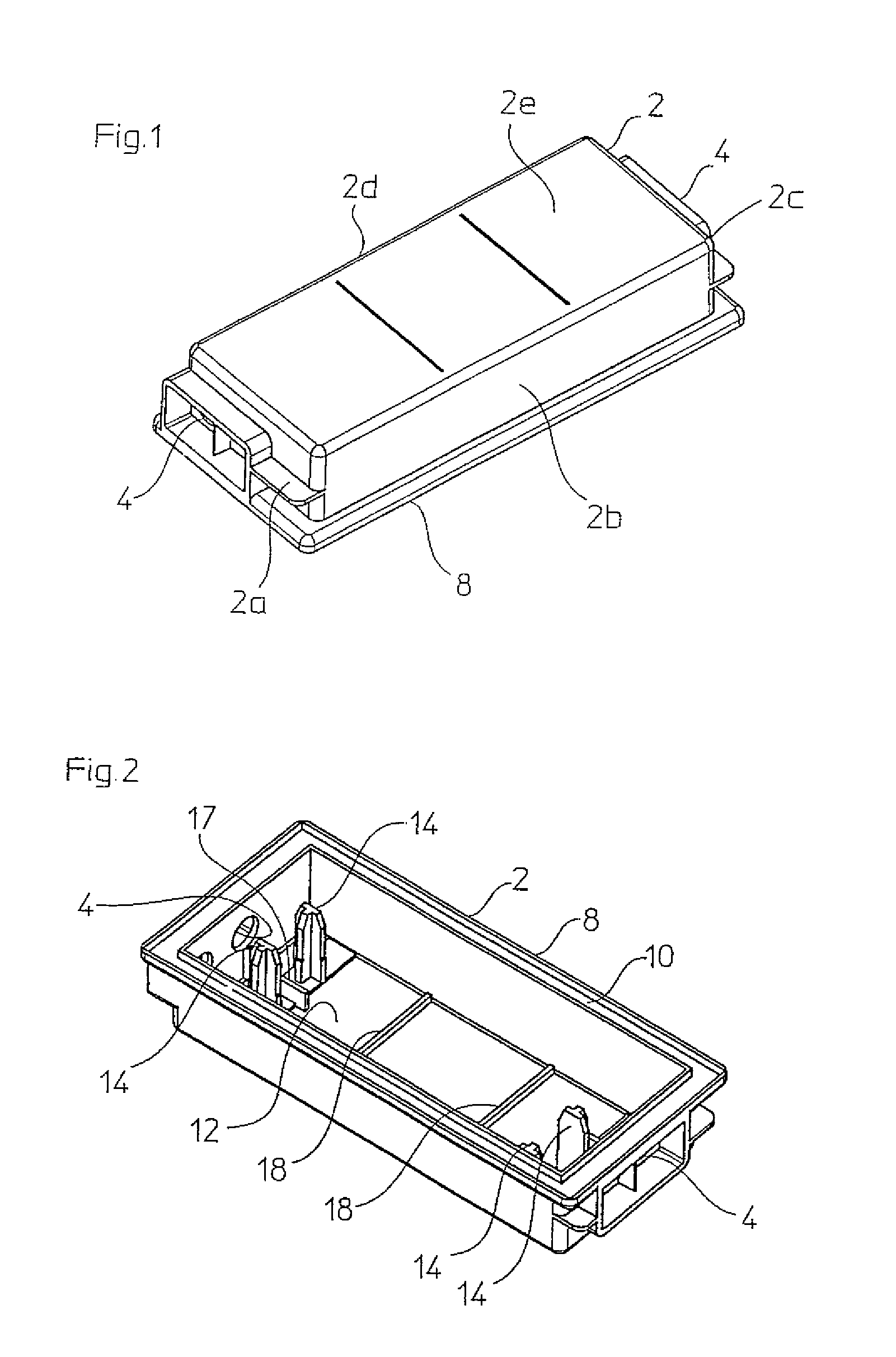

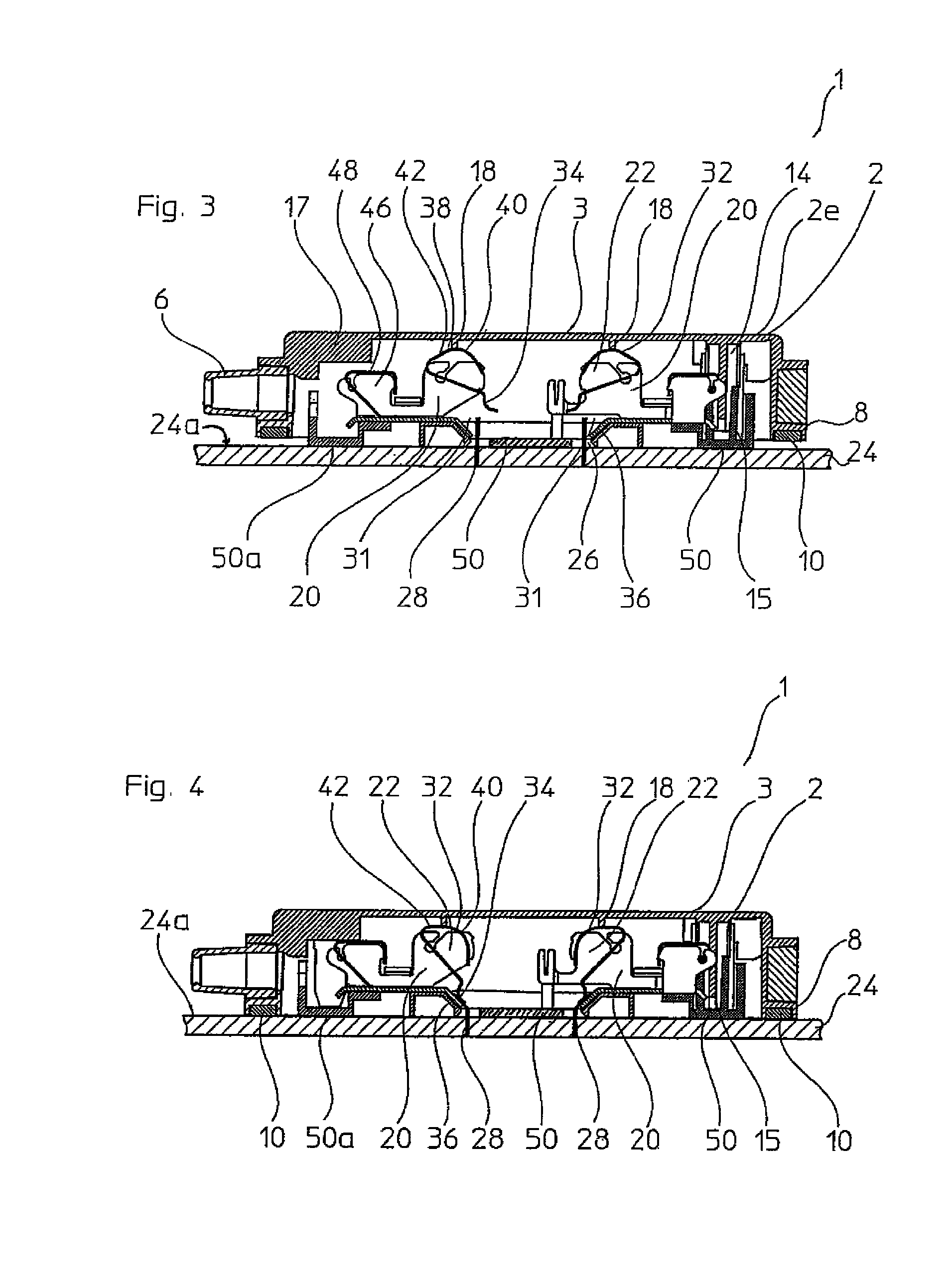

[0043]With reference to FIGS. 1-2, the connection and junction box has a housing cap 2 made of plastics. The housing cap 2 is formed by a substantially rectangular frame made of four side walls 2a to 2d, and of a closed cap plate 2e running parallel to the solar module. The housing cap 2 is closed on five sides and open downward. For example, it is injection-moulded from plastics. Separate fold protection grommets 6 (see FIG. 3 and FIG. 4) are each inserted into connection cable lead-throughs 4.

[0044]Referring to FIG. 2, the housing cap is downward open, and has a holding frame 8 projecting outward, which frame has a circumferential glue notch 10 so that the housing cap 2 has a hat-like shape. Finally, the connection and junction box is permanently glued on the solar module by means of the glue inserted in the glue notch 10. The hat-like or pan-like shape of the housing cap forms an inner hollow space 12, in which the connection devices not shown in FIG. 2 are substantially water-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com