Cable bundling device

a cable and cable technology, applied in the field of cable bundling, can solve the problems of inability to effectively improve the performance and throughput of production, degrade the quality of the final product of the ribbon cable, and the inability to achieve the effect of improving the efficiency and throughput of conventional methods, enhancing the aesthetics of the bundling, and simplifying the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

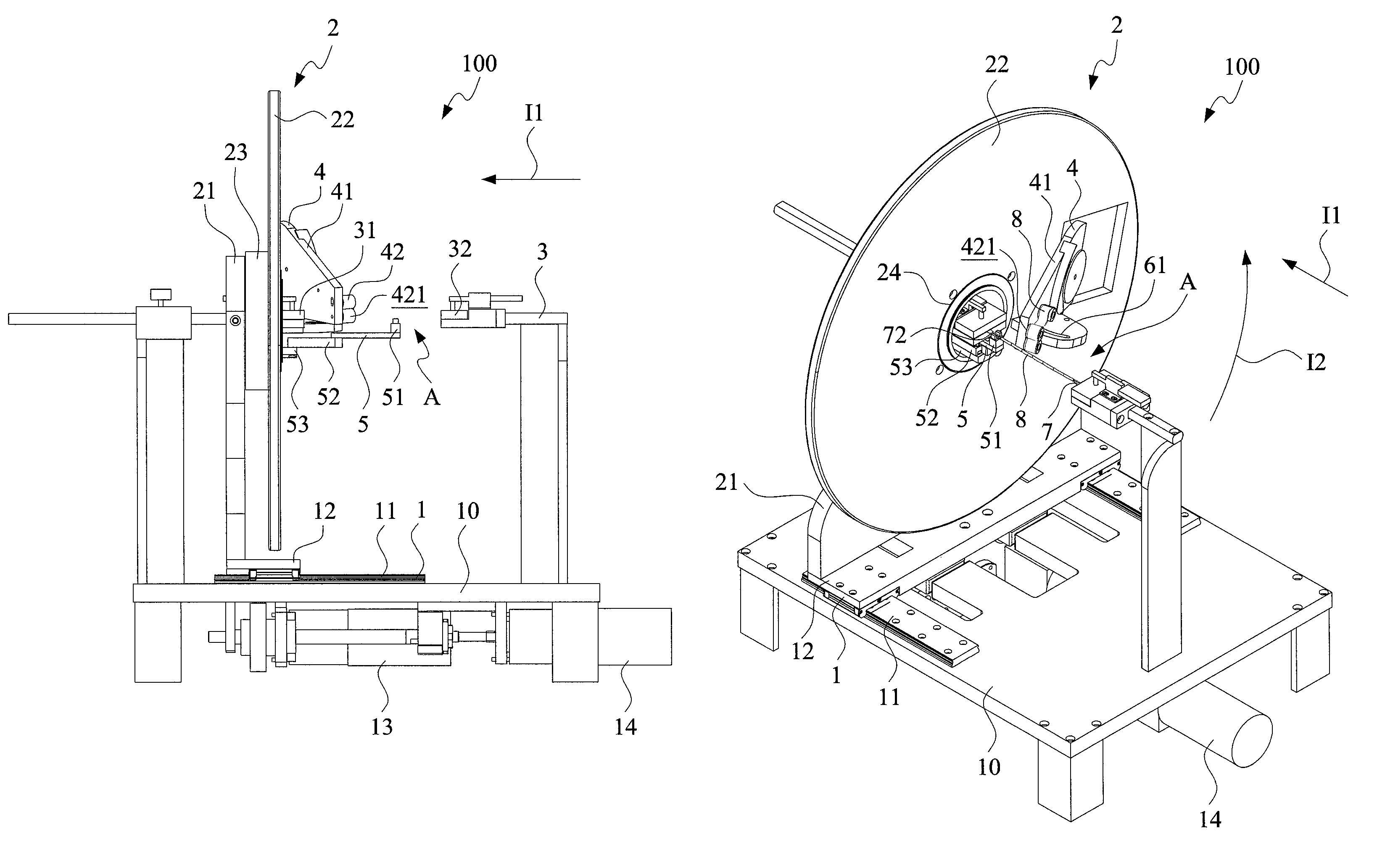

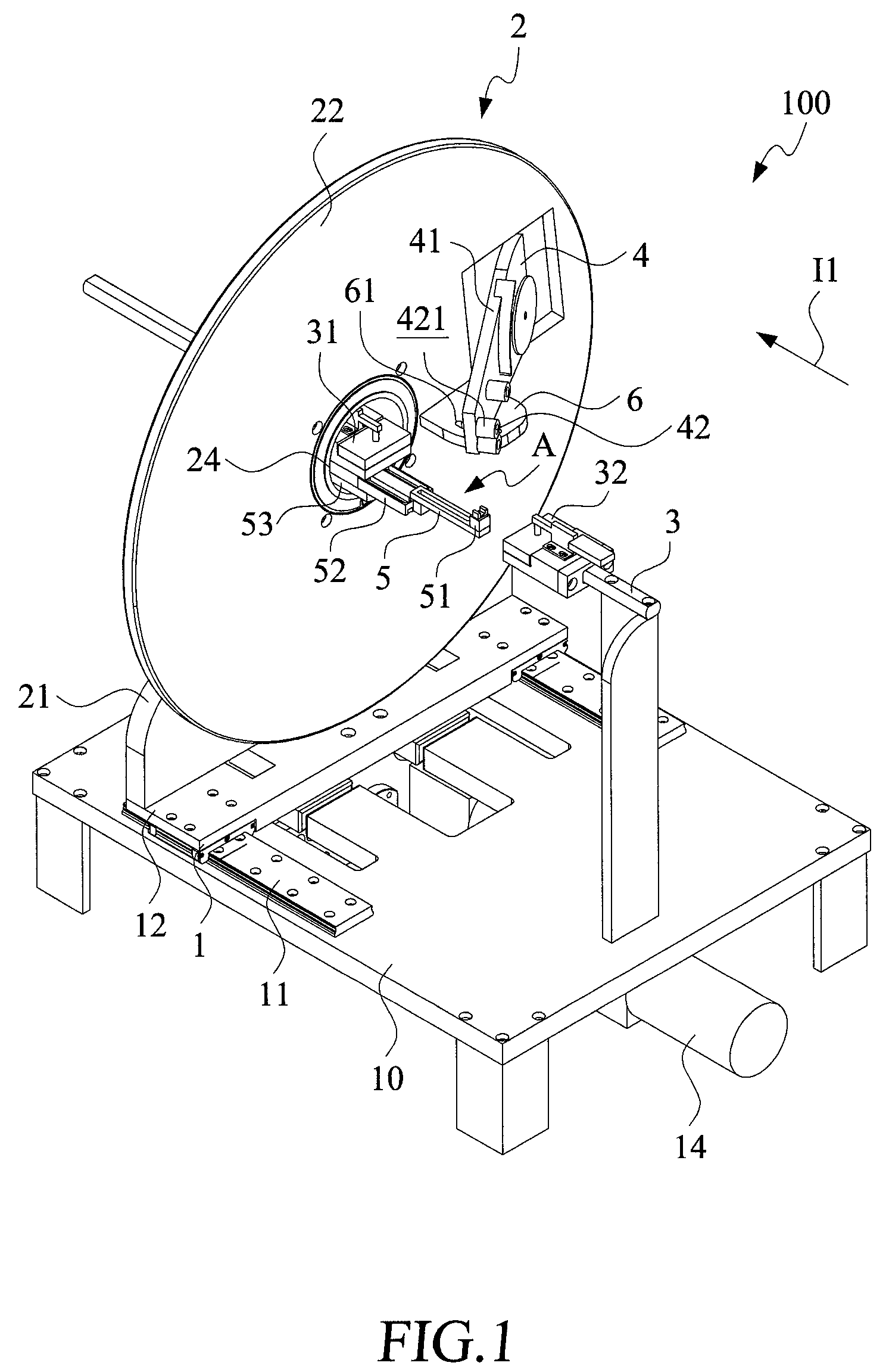

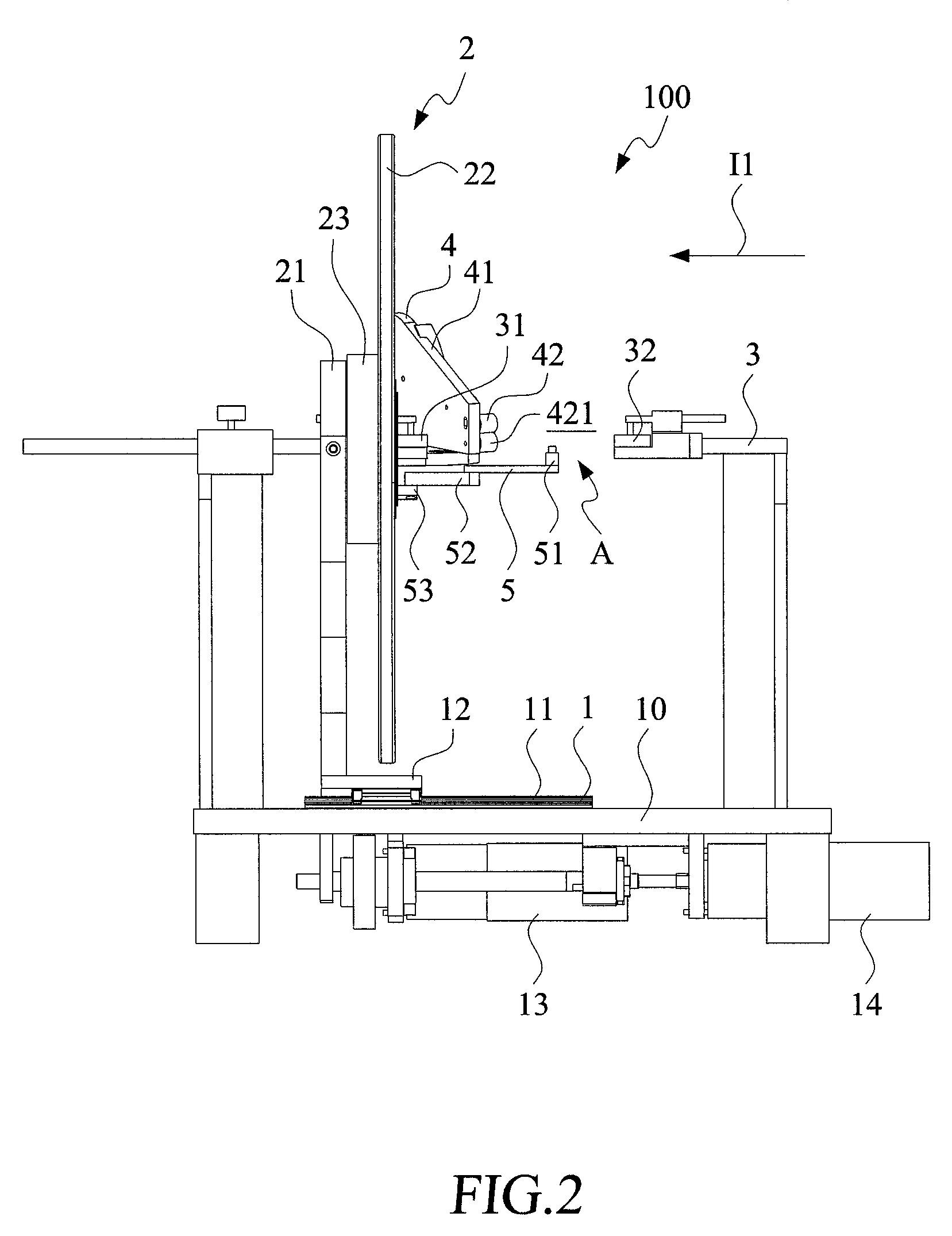

[0027]With reference to the drawings and in particular to FIGS. 1 and 2, a cable bundling device constructed in accordance with a first embodiment of the present invention, generally designated at 100, comprises a track assembly 1, a rotation mechanism 2, a cable positioning mechanism 3, and a wrapping mechanism 4. The track assembly 1 comprises a track 11 mounted on a chassis 10 and a slide 12, which is slidably mounted to the track 11. The slide 12 is coupled to a drive unit 13, and the slide 12 can be driven by the drive unit 13 to slide on the track 11 in an axial movement direction 11.

[0028]The rotation mechanism 2 comprises a support base 21 and a rotary unit 22. The support base 21 is mounted to the slide 12 of the track assembly 1. The rotary unit 22 is coupled to a predetermined position on the support base 21 through a transmission assembly 23. In the instant embodiment, the rotary unit 22 comprises a rotatable wheel. The transmission assembly 23 is driven by a drive unit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrically conductive | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com