Method for detecting the position of a closure element in a water distribution mechanism

a technology of closure element and water distribution mechanism, which is applied in the direction of cleaning equipment, process and machine control, instruments, etc., can solve the problems of high complexity of the changeover device and the increase of the cost of producing the dishwasher, and achieve the effect of more economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

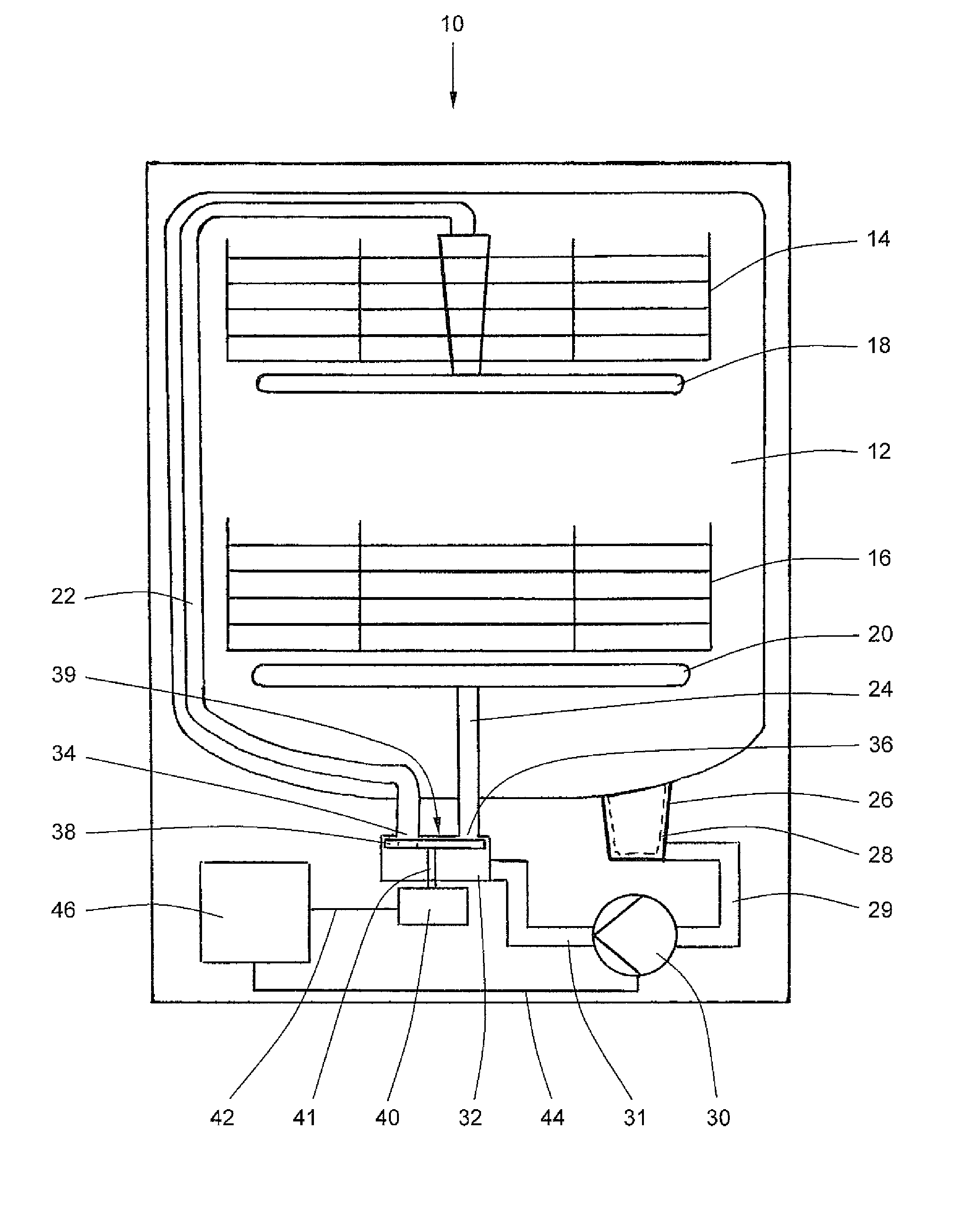

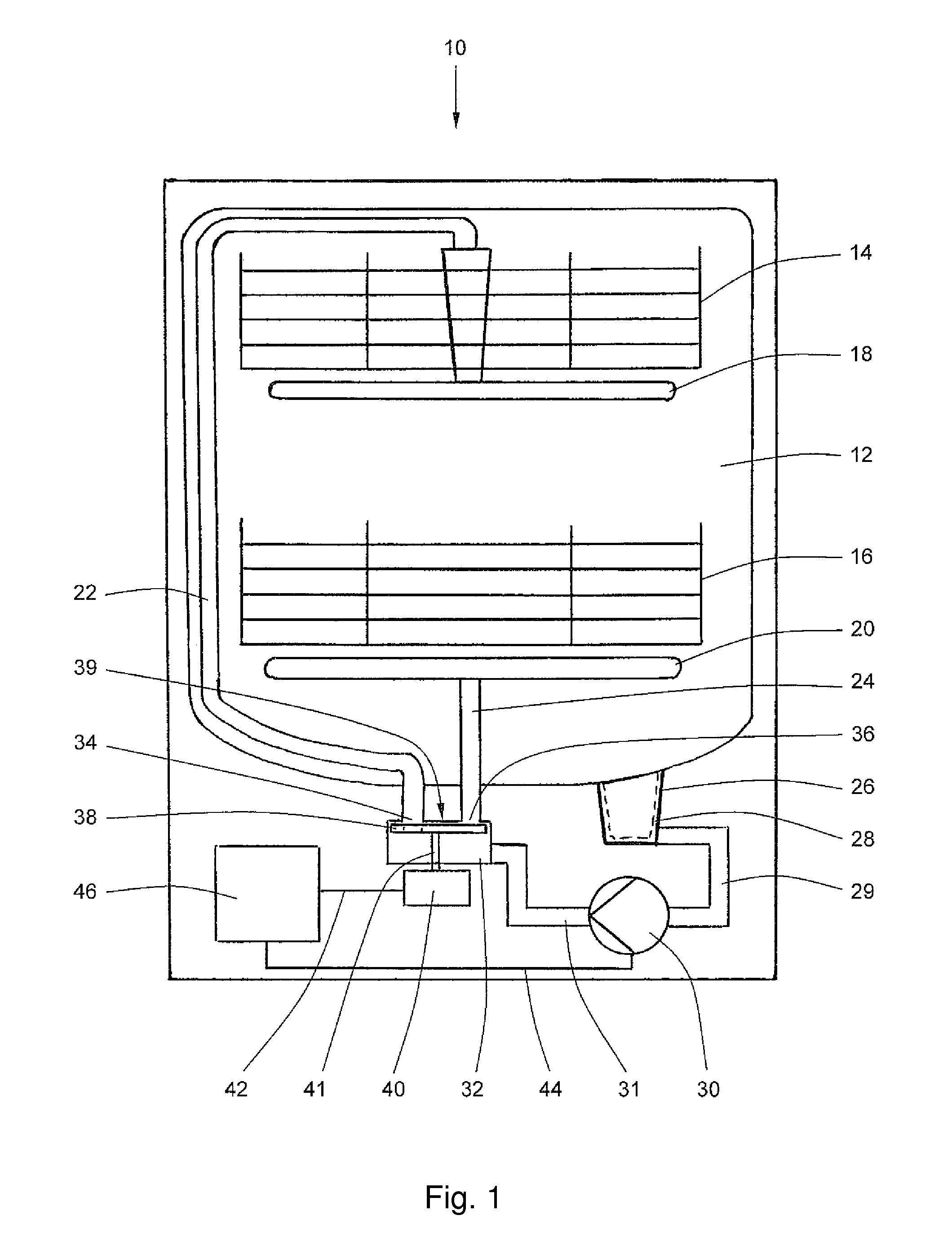

[0018]FIG. 1 is a schematic of a dishwasher 10 having a washing container 12 in which are located an upper basket 14 and a lower basket 16. Mounted rotatably below the upper basket 14 is an upper spraying system 18 and below the lower basket 16 is a lower spraying system 20 each in the form of a spraying arm. The upper spraying system 18 is supplied via a feeder line 22 and the lower spraying system via a feeder line 24 with rinsing fluid. Located below the washing container 12 is a sump 26 having a filter insert 28 that is linked via a fluid line 29 to a circulating pump 30. The circulating pump 30 is connected via a fluid line 31 to a water diverter 32. It has a covering surface 39 having two openings 34, 36, with the opening 34 being linked to the feeder line 22 and the opening 36 to the feeder line 24.

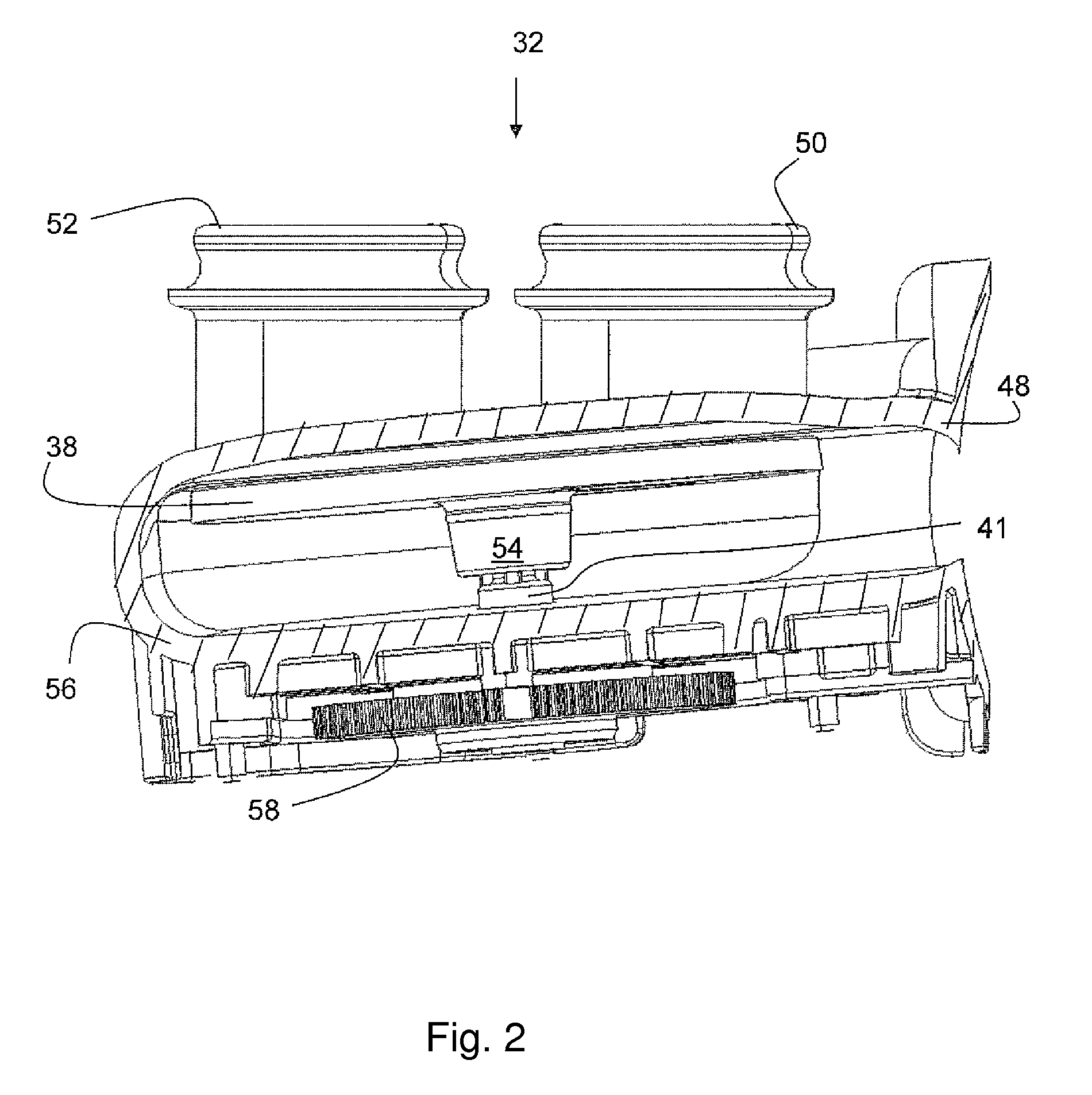

[0019]Mounted rotatably inside the cylindrical water diverter 32 parallel to the covering surface 39 is a discoid closure element 38. It is arranged in a rotationally fixed manner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com