Laminated and sintered ceramic circuit board, and semiconductor package including the circuit board

a technology of laminated and sintered ceramics and circuit boards, which is applied in the manufacture of printed circuits, printed circuit aspects, metallic pattern materials, etc., can solve the problems of wiring (disconnection, reliability decline), etc., and achieve low open failure rate, high reliability, and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

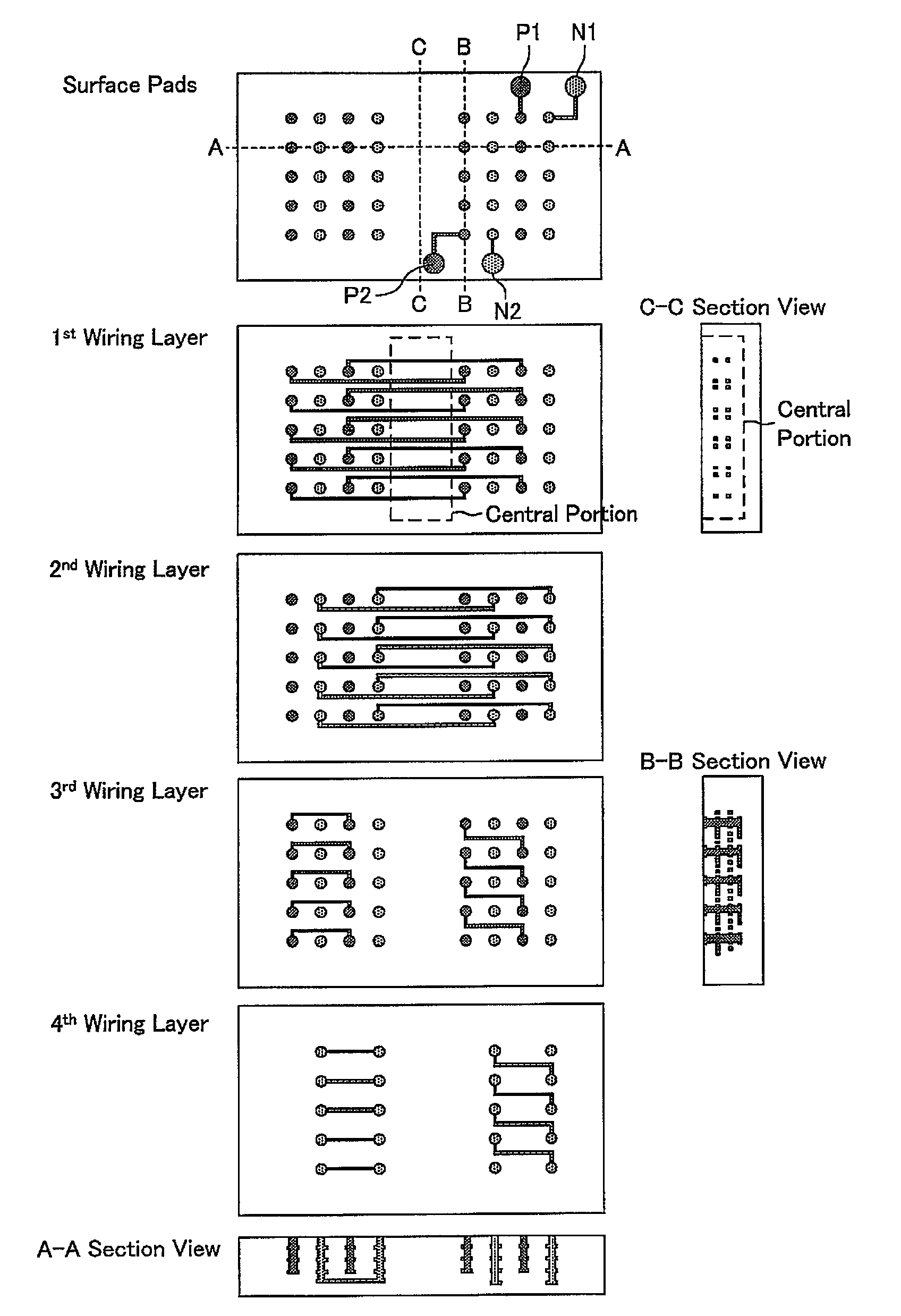

first embodiment

is the present invention.

[0060]As described above, the laminated and sintered ceramic circuit board according to the present embodiment comprises a base material comprising a plurality of dielectric layers of ceramic. As mentioned previously, ceramic has a coefficient of thermal expansion close to that of silicon constituting a semiconductor element. Accordingly, in the laminated and sintered ceramic circuit board according to the present embodiment, even when the board in a condition where it is joined with a semiconductor element is exposed to temperature alteration as mentioned previously, the difference between dimension change of the semiconductor element and that of the board is small. As a result, in the laminated and sintered ceramic circuit board according to the present embodiment, thermal stress acting between the semiconductor element and the board can be suppressed.

[0061]Thereby, problems such as breakdown of a joining part between a semiconductor element and a board, d...

second embodiment

is the present invention.

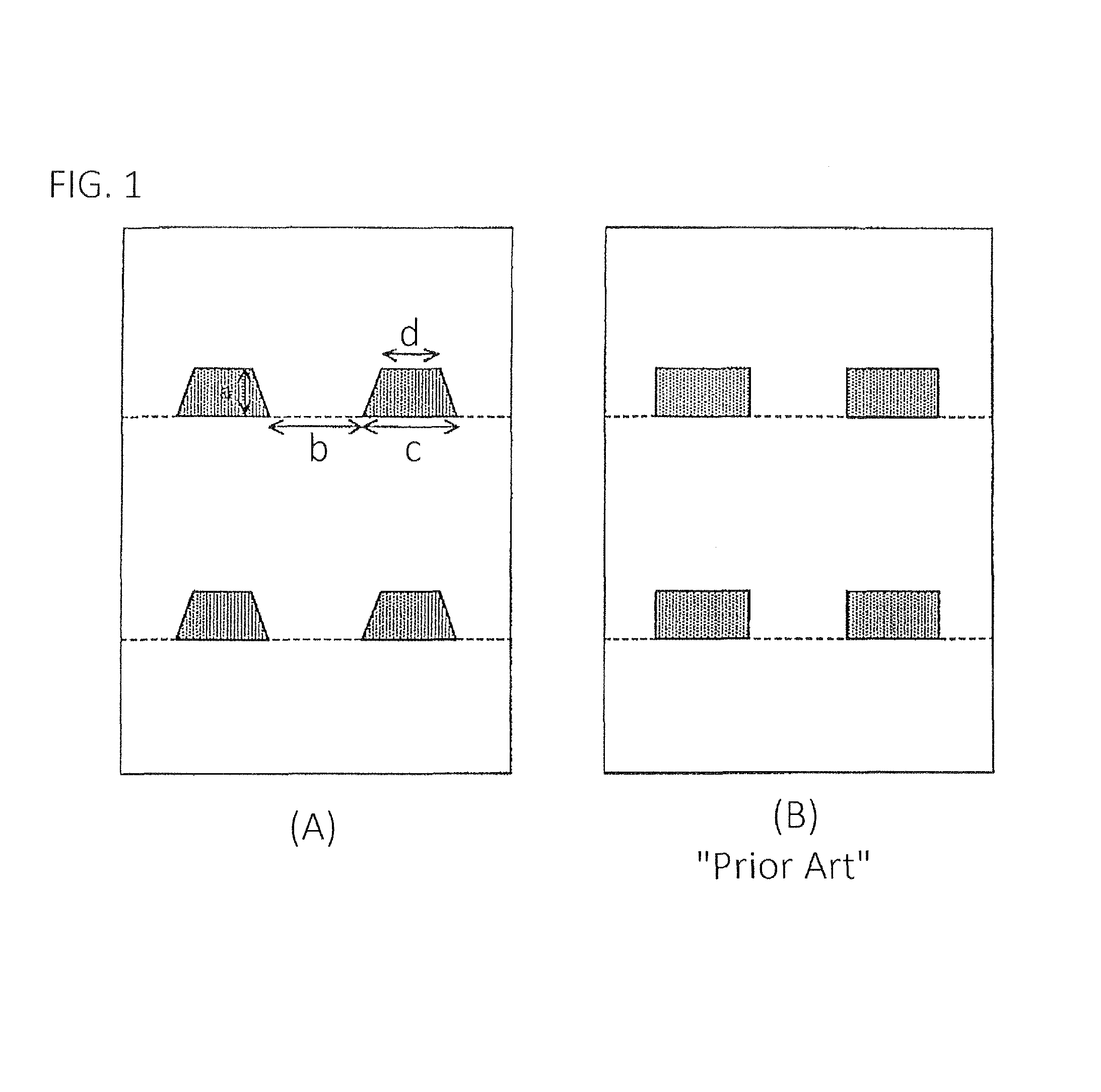

[0097]As described above, the laminated and sintered ceramic circuit board according to the present embodiment is configured so that the ratio (d / c) of the length (d) of the upper base to the length (c) of the lower base of the trapezoidal cross-section surfaces of inplane conductors constituting the fine-lined inplane wiring is −½*(a / b)+0.93 or more, and −½*(a / b)+1.10 or less. Thereby, detachment and lack of conductor pattern as mentioned previously, and void at a corner portion formed by the side surfaces of conductor patterns and the surface of protective substrate or green sheet become more unlikely to occur. As a result, the laminated and sintered ceramic circuit board according to the present embodiment can further decrease problems such as open failure, decrease in reliability against high temperature and high humidity and the like.

[0098]By the way, a method for manufacturing the laminated and sintered ceramic circuit boards according to the previousl...

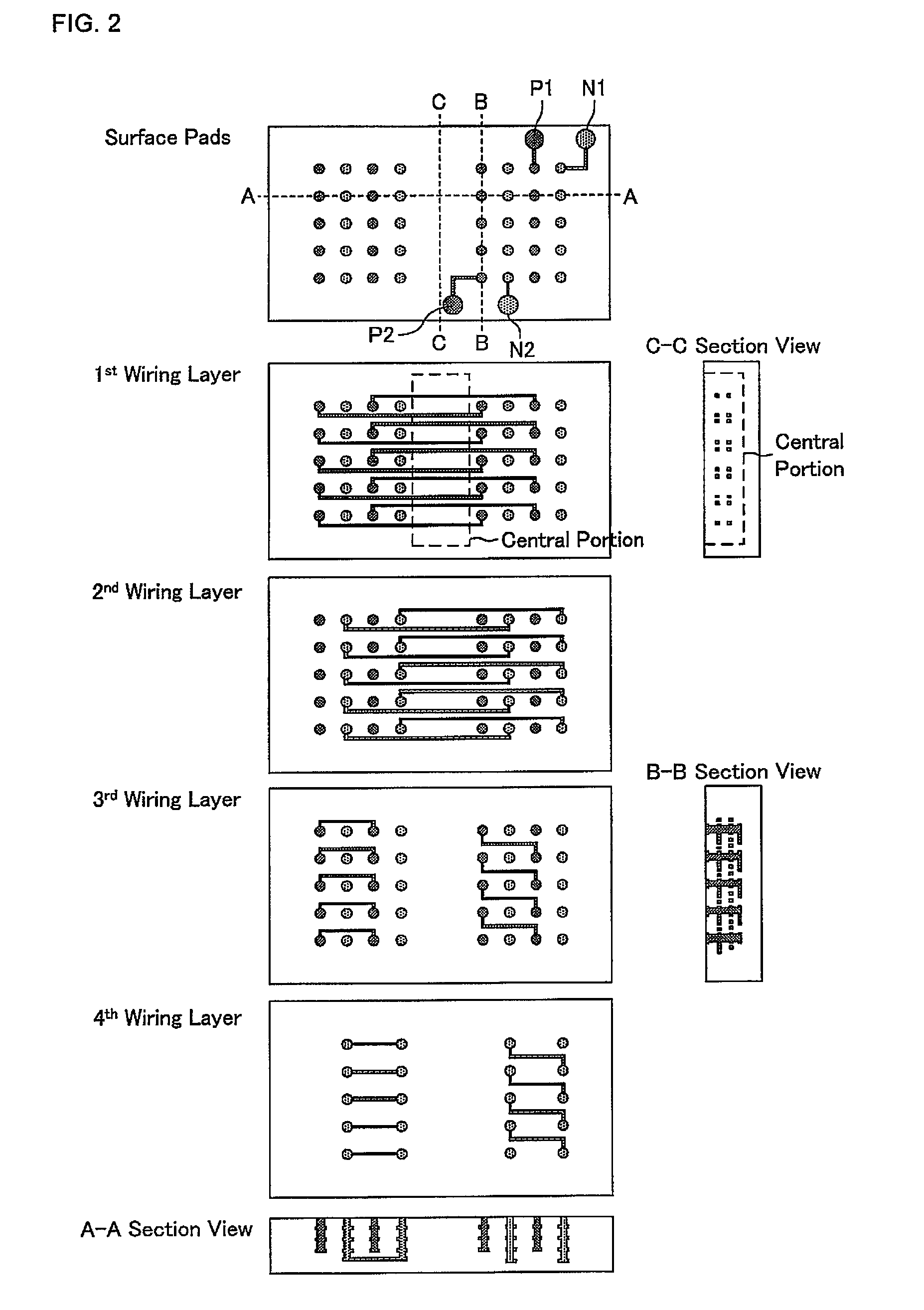

seventh embodiment

is the present invention.

[0149]In addition, as a more preferable embodiment, the semiconductor package according to the seventh embodiment of the present invention, wherein:

[0150]the height (a), the interval (b), the length (c) of the lower base and the length (d) of the upper base of the trapezoidal cross-section of inplane conductors constituting the fine-lined inplane wiring meet the relation represented by the following formula (3):

[0151]-12×ab+0.93≤dc,dc≤-12×ab+1.10(3)

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com