Method and device for producing alkylene oxides and alkylene glycols

a technology of alkylene oxide and alkylene glycol, which is applied in the preparation of oxygen-containing compounds, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of high cod value or a very high burden of biodegradable substances, high energy consumption, and large amount of energy to be introduced, so as to improve the efficiency of these processes and achieve the effect of more economic preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

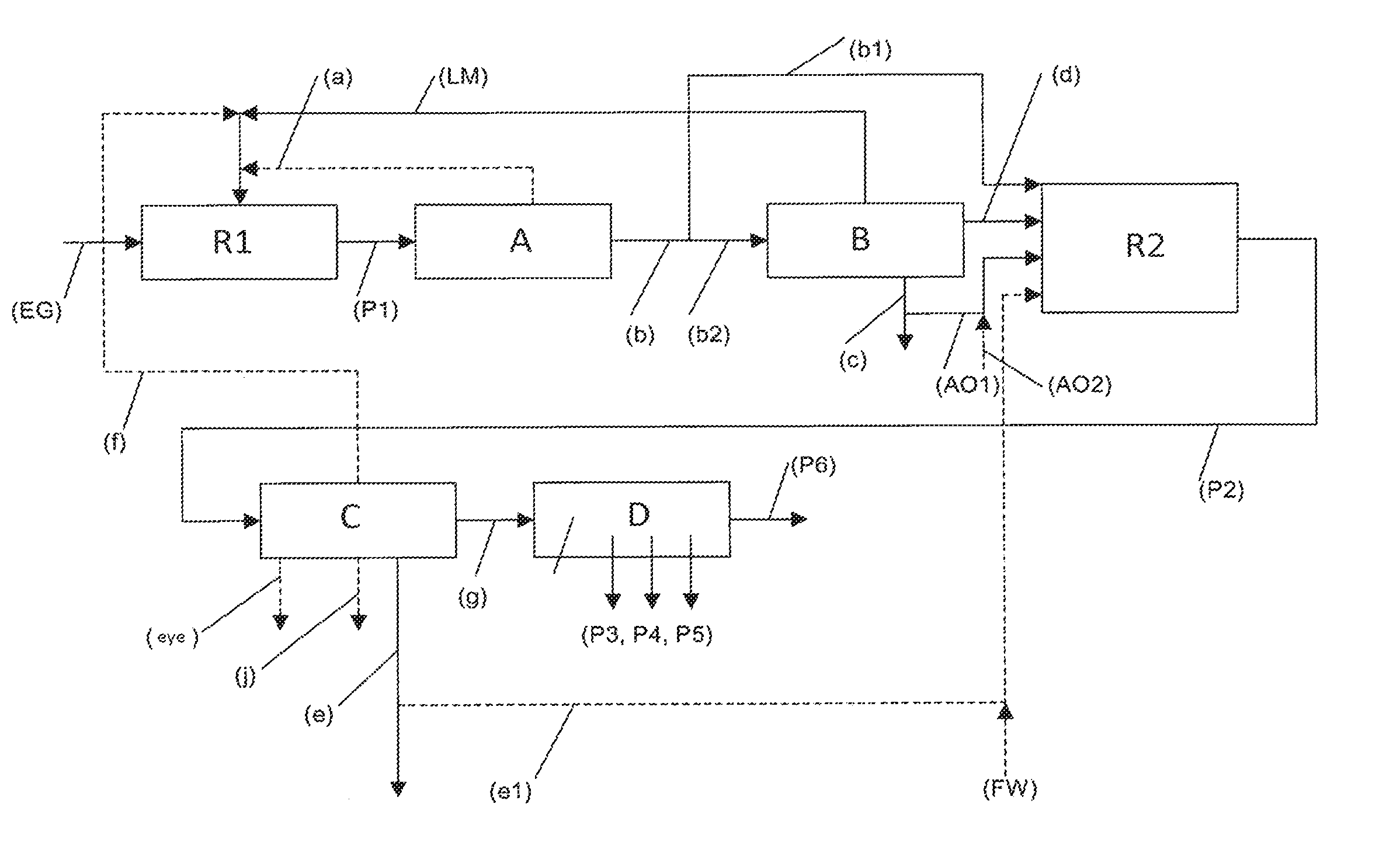

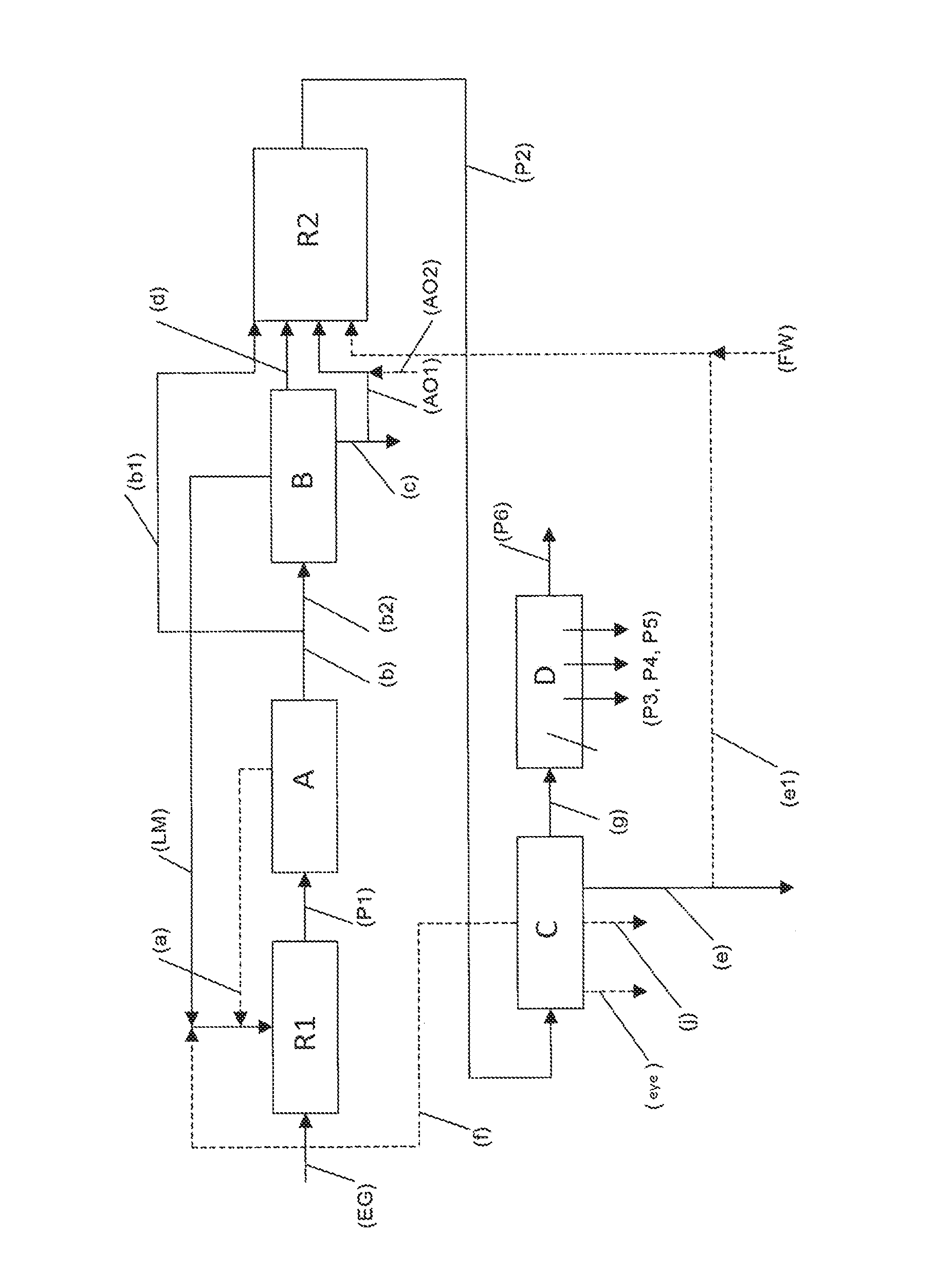

Image

Examples

Embodiment Construction

[0028]In the process of the invention, the alkylene glycol-containing and optionally alkylene glycol ether-containing process water stream from the alkylene oxide plant is, if appropriate after setting of a particular pH, introduced directly into the reactor of the alkylene glycol plant and after being separated off, for example by distillation, is discharged from the alkylene glycol plant. When the capacity is chosen appropriately, the energy-intensive recirculation of water can be dispensed with. If further valuable components are present in the wastewater, the wastewater can be subjected to a further treatment before being introduced into the wastewater treatment. The dewatered glycols are preferably separated by distillation into the monoalkylene glycol, dialkylene glycol and trialkylene glycol and if appropriate higher alkylene glycols. Since alkylene oxide plants and alkylene glycol plants are often operated on the same site, the invention is also suitable for reequipping and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com