Articulated cutting head and conveyor mount for sod harvesting machines

a cutting head and conveyor mount technology, applied in lawn machines, agriculture tools and machines, turf growing, etc., can solve the problems of adversely affecting the quality of turf, difficult subsequent laying of slabs, and end and thus less stable, and achieve high transverse stiffness, high lifting of cutting heads, and robust and durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

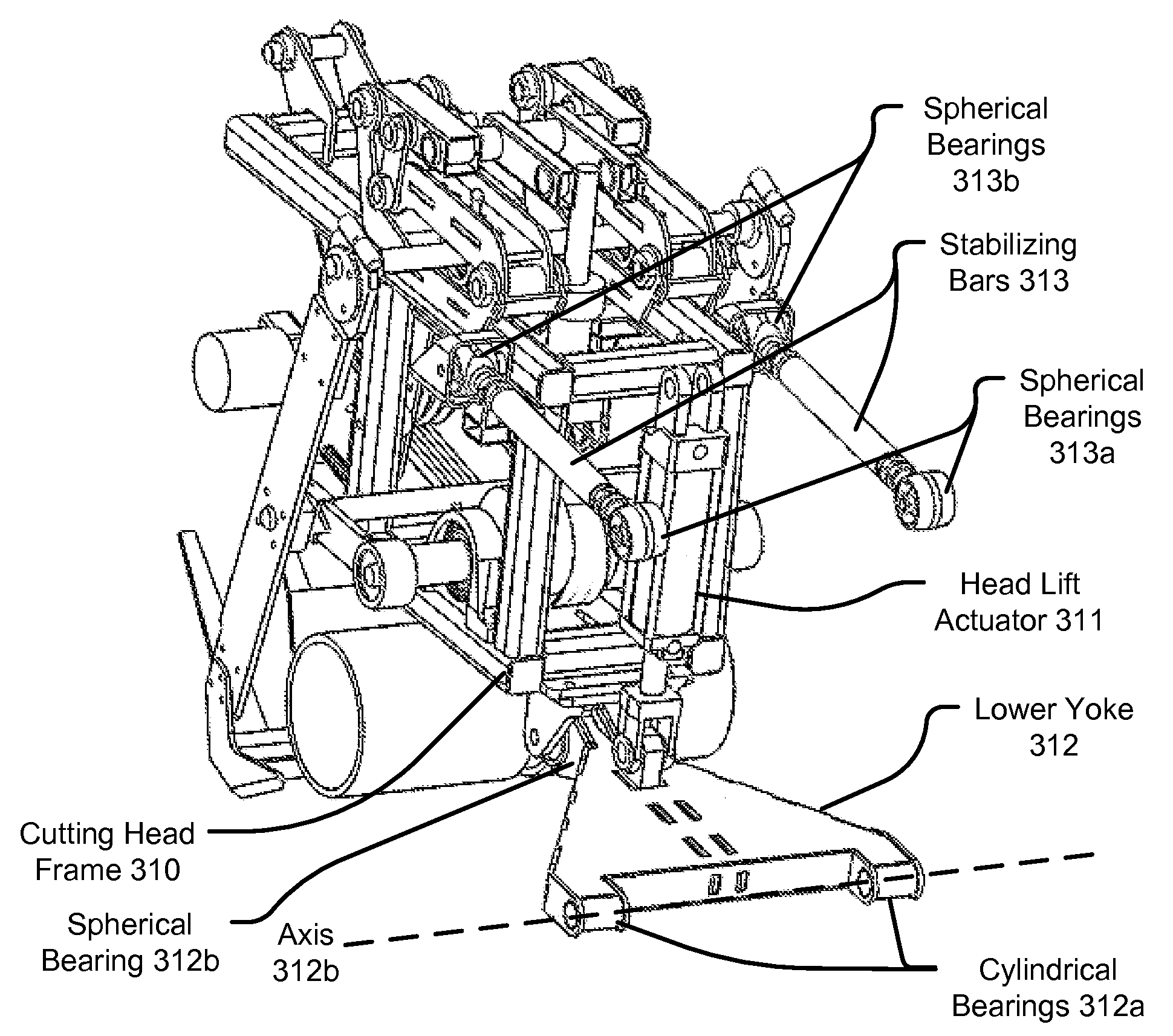

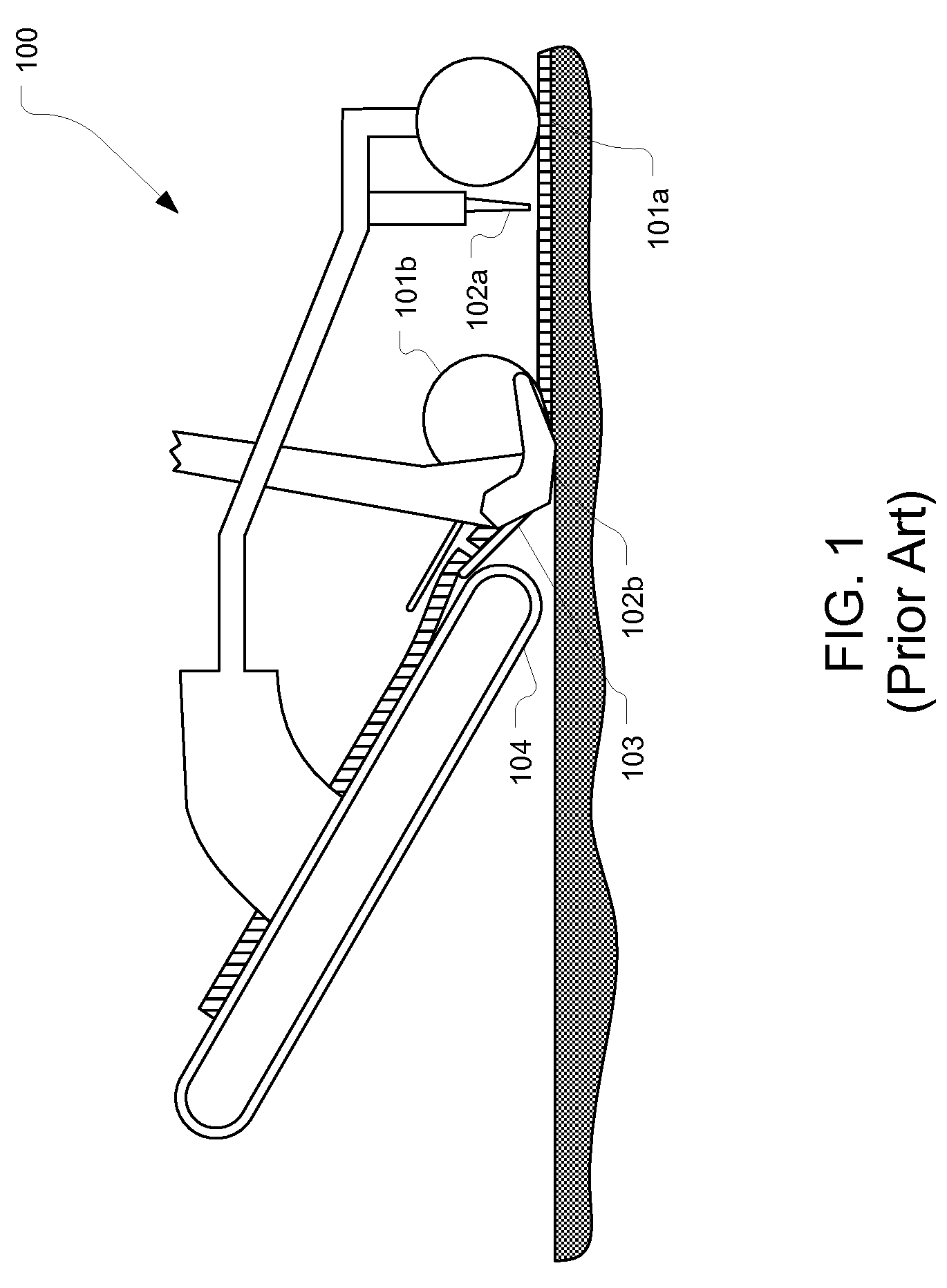

[0024]The present invention extends to an articulated cutting head and conveyor mount for sod harvesting machines. The invention provides a linkage design that can provide many benefits including: allowing the operator to see the cutting operation, enabling the high lifting of the cutting head for service and maneuvering, managing the vertical bending load of the ground reference roller, providing high transverse stiffness, and maintaining the position of the conveyor relative to the cutting head. The linkage design can include fewer parts than previous designs while still being robust and durable. As such, cutting heads employing the linkage design of the present invention can produce higher quality slabs with less service and maintenance than when using current designs.

[0025]In some embodiments, the present invention is implemented as a linkage system for a cutting head of a sod harvesting machine. The linkage system comprises a head boom extending from the sod harvesting machine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com