Inkjet recording ink and inkjet recording device using the same

a technology of inkjet recording and inkjet printing, which is applied in the direction of printing, duplicating/marking methods, and inks, can solve the problems of pigment-based inks being more likely to cause nozzle clogging, poor light resistance of dye-based inks, and low reliability of images obtained using dye-based inks, etc., to achieve excellent jetting stability and fluid stability of inks, high image density, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

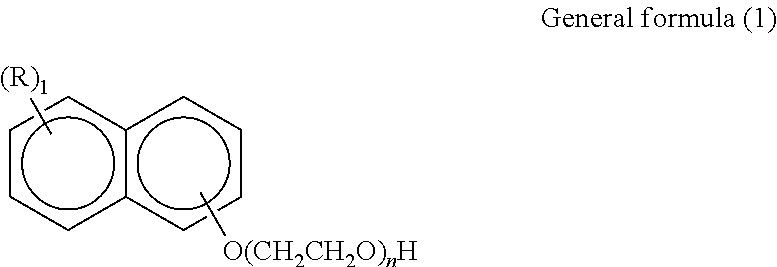

Method used

Image

Examples

examples

[0117]The present invention will be specifically explained with reference to examples hereinafter, but these examples shall not be construed as limiting the scope of the present invention in any way. Note that, “part(s)” described in the following examples are all on mass basis.

[0118]A volume average particle diameter (D50) of particles in a pigment dispersion liquid was measured by means of a particle size analyzer (UPA150EX, manufactured by NIKKISO CO., LTD.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com