Vented ballistic combat helmet

a technology of ballistic armor and helmets, applied in the field of ballistic armor helmets, can solve the problems of inefficient use of materials, increased cost of modern ballistic materials, and inability to develop deep compound curves, etc., and achieves the effects of reducing cost, reducing material waste, and reducing material was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

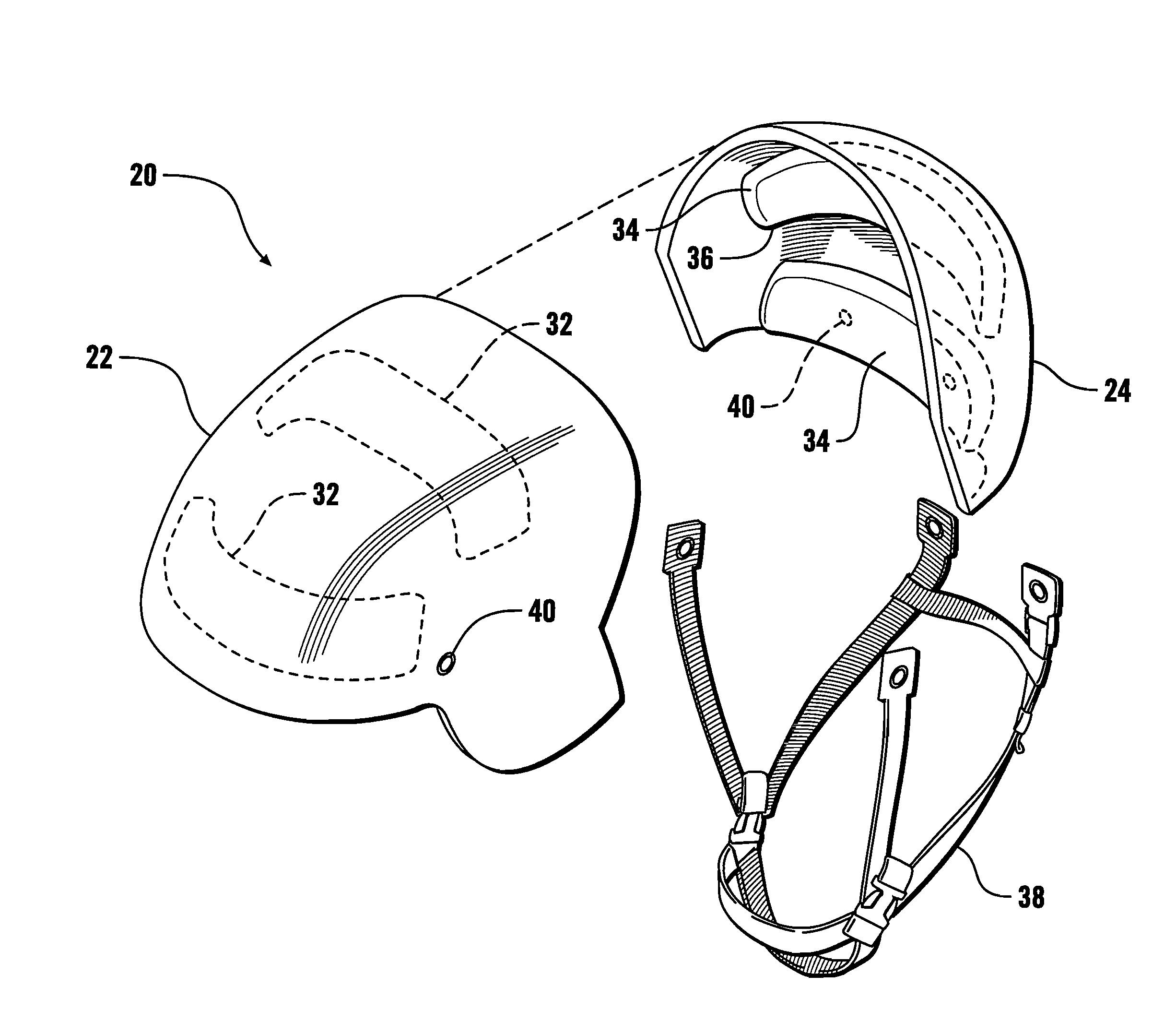

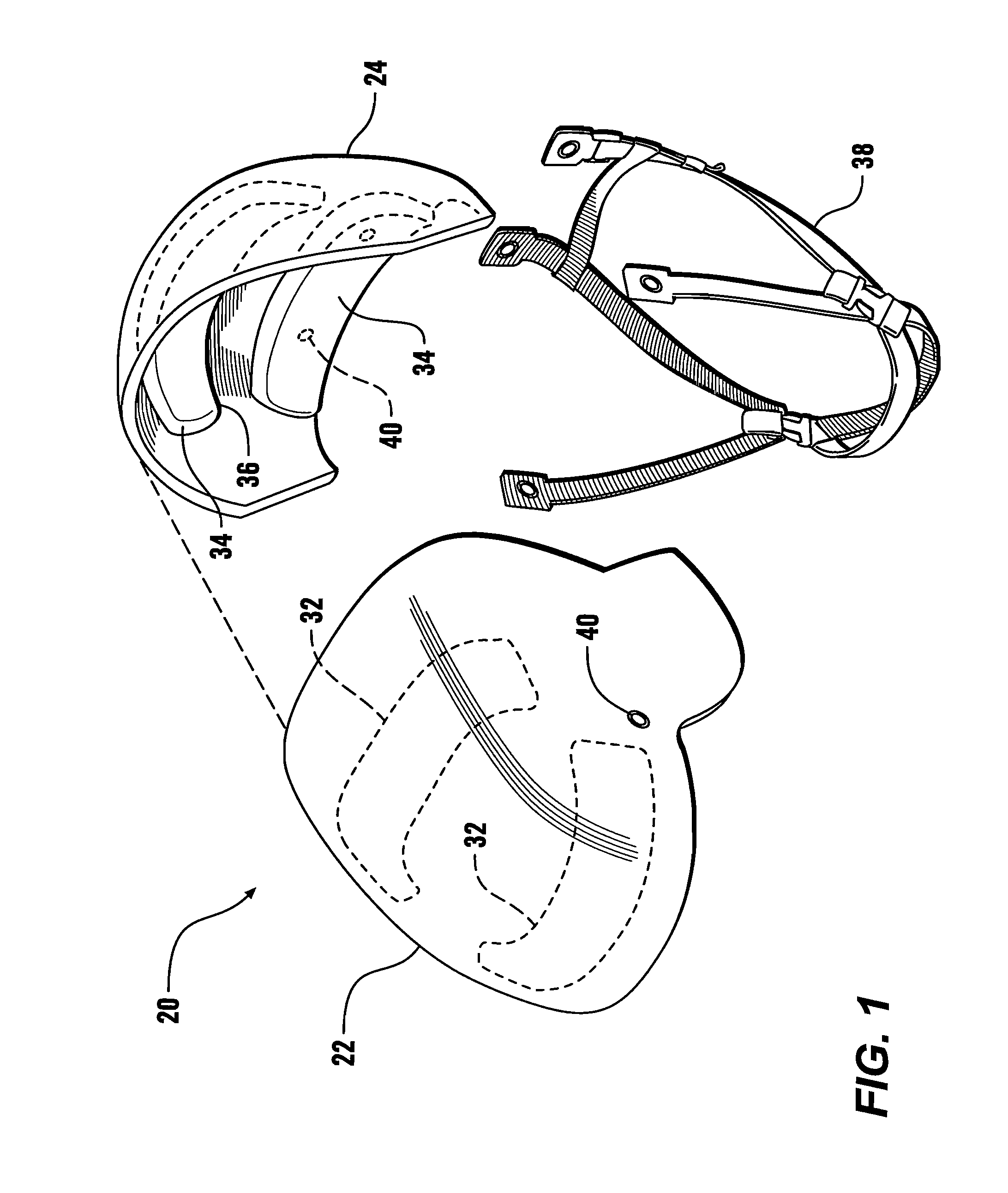

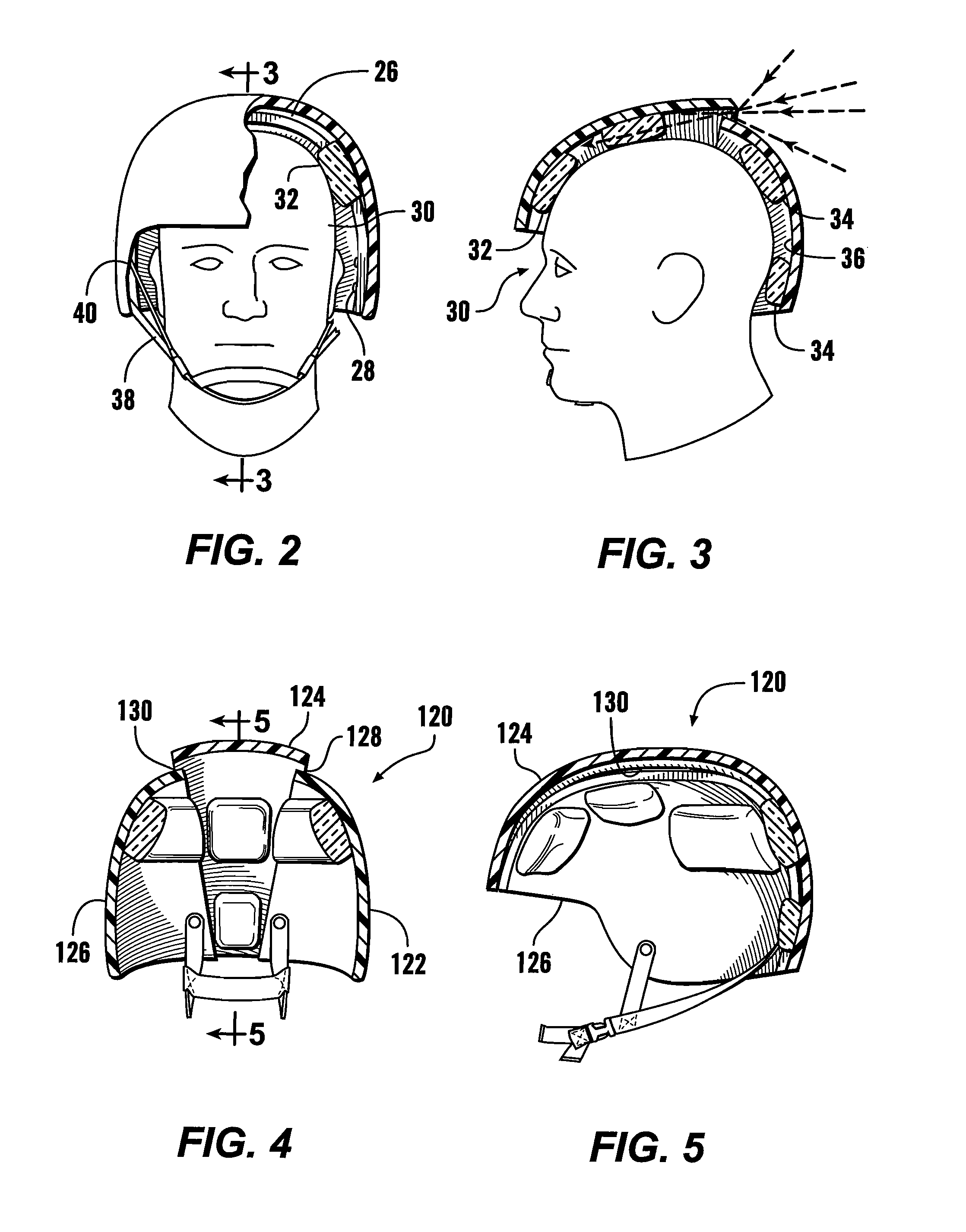

[0027]Referring more particularly to FIGS. 1-14, wherein like numbers refer to similar parts a ballistic helmet 20 is illustrated in FIG. 1-3. The helmet has a front portion 22 and a rear portion 24 which are joined together to form the helmet 20. Both the front portion 22 and the rear portion define distinctly formed shell elements, which, when assembled, define the complete ballistic protective helmet. By “ballistic protective material” is meant a material which is capable of stopping a ballistic projectile, ranging from low velocity projectiles such as various shrapnel and explosive fragments, to typical handgun rounds, to high speed rifle rounds. Ballistic protective elements will typically be rated from low, for example capable of stopping a handgun round, to high, for example capable of stopping a rifle round. An element which has a high ballistic rating is better able to protect against faster, more pointed, or more massive items impacting the element.

[0028]As shown in FIG. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com