Single phase motor with positive torque parking positions

a single-phase, positive technology, applied in the direction of instruments, lighting and heating apparatus, magnetic circuit shape/form/construction, etc., can solve the problems of difficult starting of the motor, more difficult to reverse the rotational direction of the rotor, and difficulty in starting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

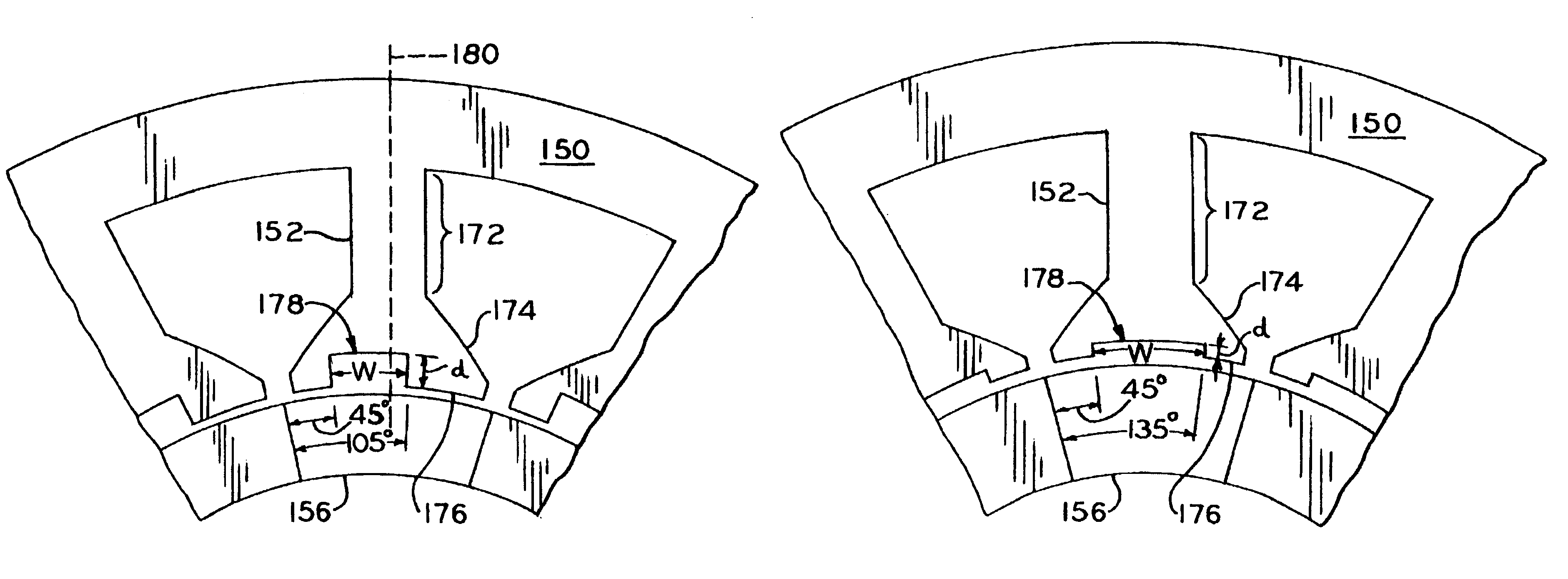

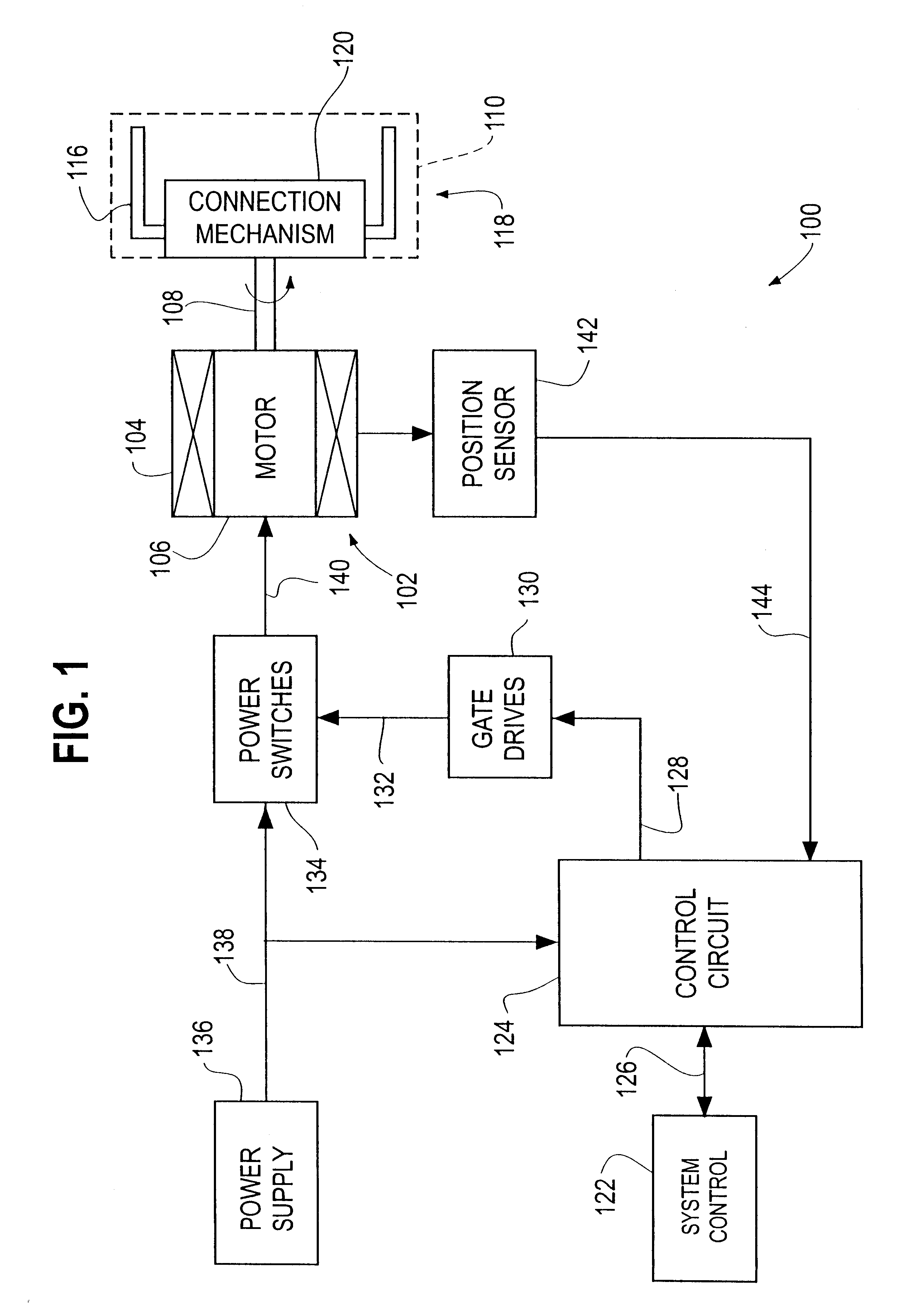

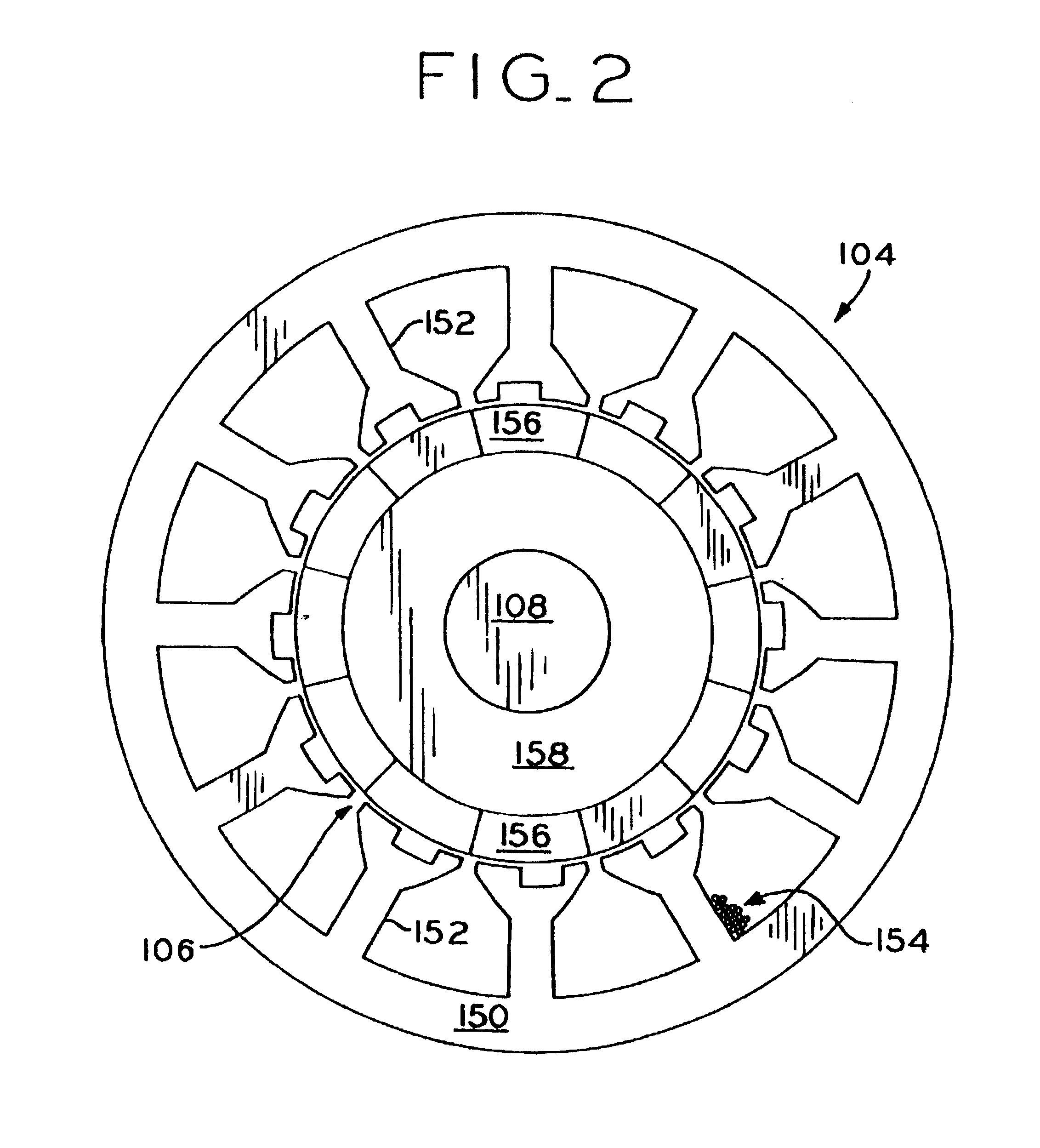

Referring now to the drawings, FIG. 1 shows a motor system 100 according to a preferred embodiment of the present invention. The system 100 includes a motor, generally designated 102, having a stationary assembly, or stator, 104 and a rotatable assembly, or rotor, 106 in magnetic coupling relation to the stator 104. In the embodiment described herein, the motor 102 is a single phase, permanent magnet motor. It is to be understood, however, that aspects of the present invention may be applied to electronically controllable motors or dynamoelectric machines such as single phase permanent magnet motors, external rotor motors (i.e., inside out motors), single and variable speed motors, selectable speed motors having a plurality of speeds, brushless dc motors and electronically commutated motors. Such motors may also provide one or more finite, discrete rotor speeds selected by an electrical switch or other control circuit.

In a preferred embodiment of the invention, a motor shaft 108 mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com