Staple and staple applicator for use in skin fixation of catheters

a catheter skin fixation and staple technology, applied in surgical staples, manufacturing tools, veterinary instruments, etc., can solve the problems of affecting the safety of patients, so as to achieve less time-consuming and safer manners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

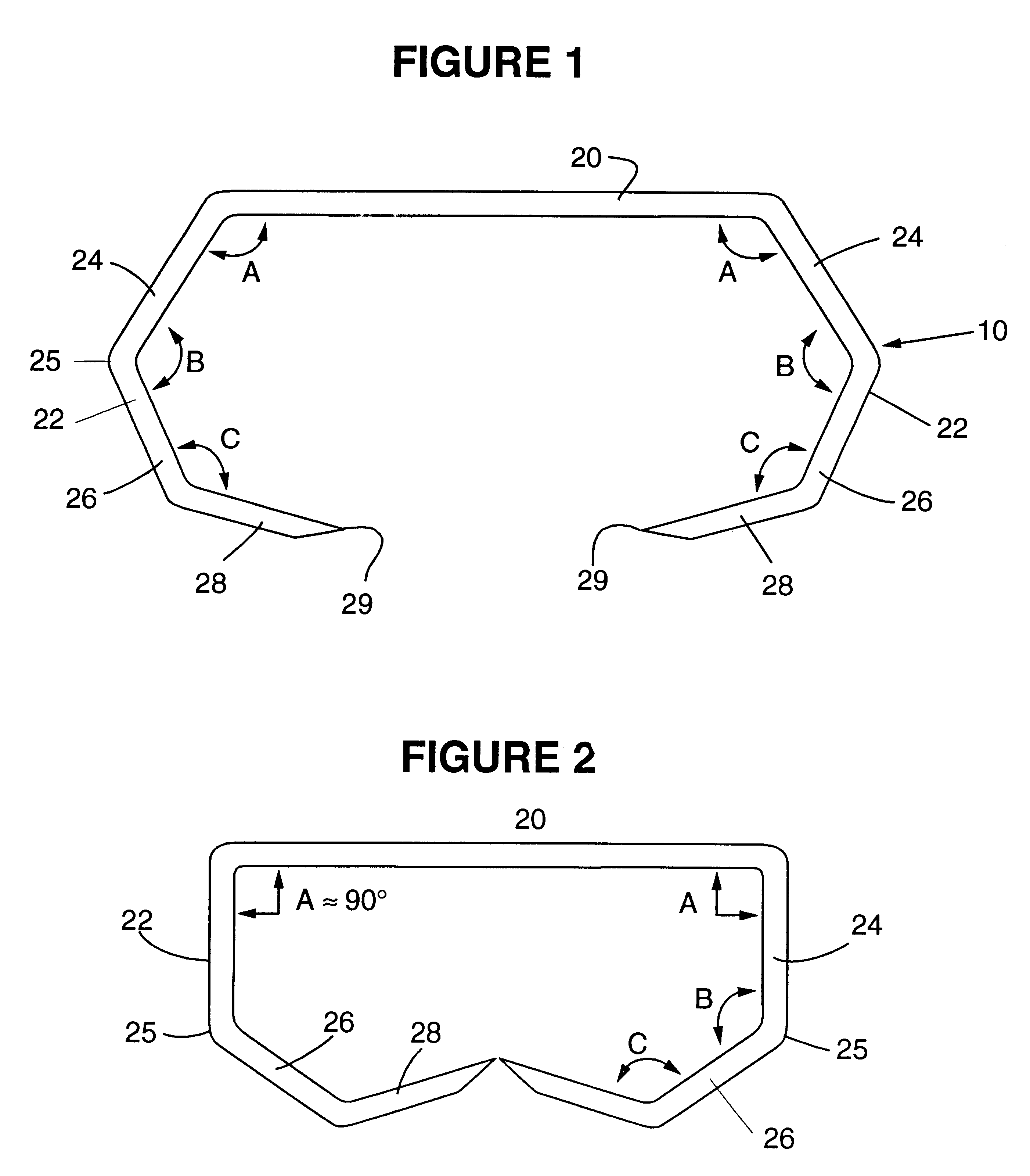

Referring now to FIG. 1, a staple 10 is constructed of stainless steel, titanium, or other similarly deformable material which retains the shape to which it has been deformed. The staple 10 includes a crown portion 20 and opposingly disposed legs 22. In the preferred embodiment, the crown 20 is generally horizontal and connected to legs 22 at each end. Legs 22 are preferably identical and comprised of three segments, 24, 26, and 28, terminating in skin piercing point 29. The three leg segments 24, 26, 28 are offset by three oblique angles A, B, and C, which are approximately 120 degrees each.

FIG. 2 depicts the staple in its closed, deformed configuration. After the staple has been completely closed and the applicator withdrawn, angle A between crown 20 and leg segment 24 should be approximately a 90 degree right angle.

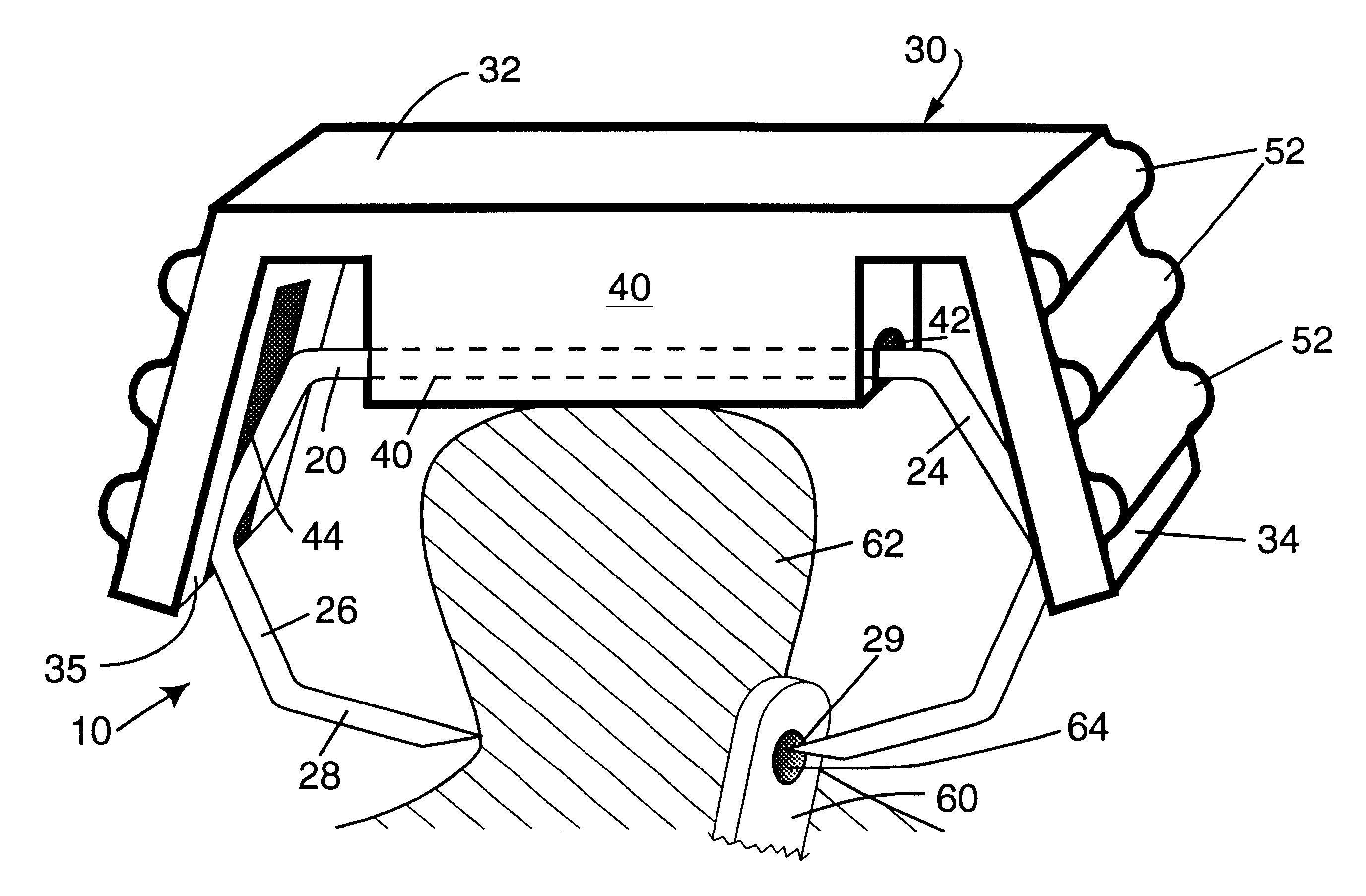

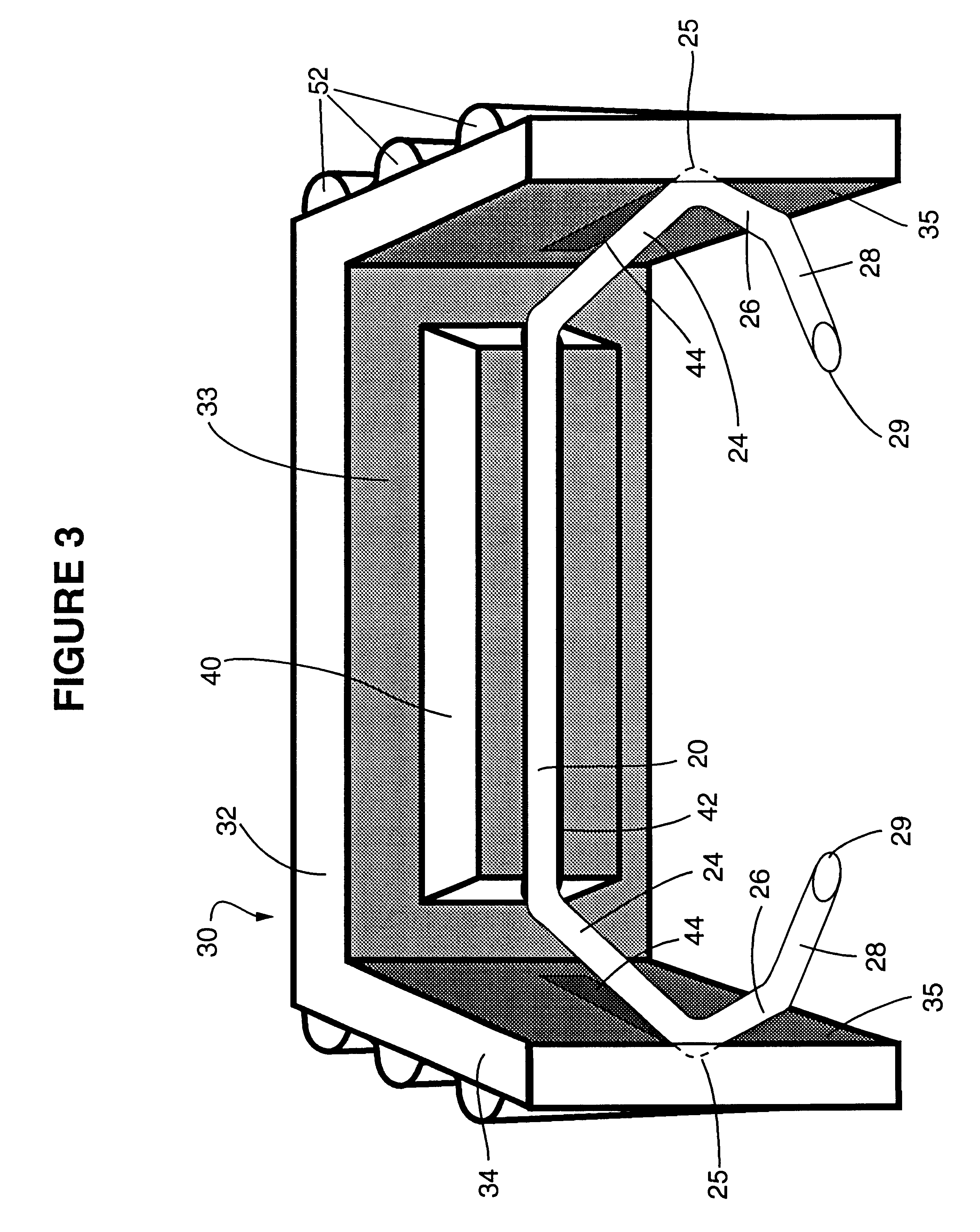

FIGS. 3, 4, and 5 depict an anvilless applicator 30 holding a staple 10 in the open position. The applicator comprises a top or backbone portion 32 and two arms 34. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com