Polyaxial pedicle screw having a threaded and tapered compression locking mechanism

a technology of compression locking and pedicle screw, which is applied in the direction of ligaments, prostheses, osteosynthesis devices, etc., can solve the problems of increasing operating time, limiting the range of motion, and considerable difficulty in inserting screws, and achieves the effect of increasing the crush locking effect on the screw head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]While the present invention will be described more fully hereinafter with reference to the accompanying drawings, in which particular embodiments and methods of implantation are shown, it is to be understood at the outset that persons skilled in the art may modify the invention herein described while achieving the functions and results of this invention. Accordingly, the descriptions which follow are to be understood as illustrative and exemplary of specific structures, aspects and features within the broad scope of the present invention and not as limiting of such broad scope.

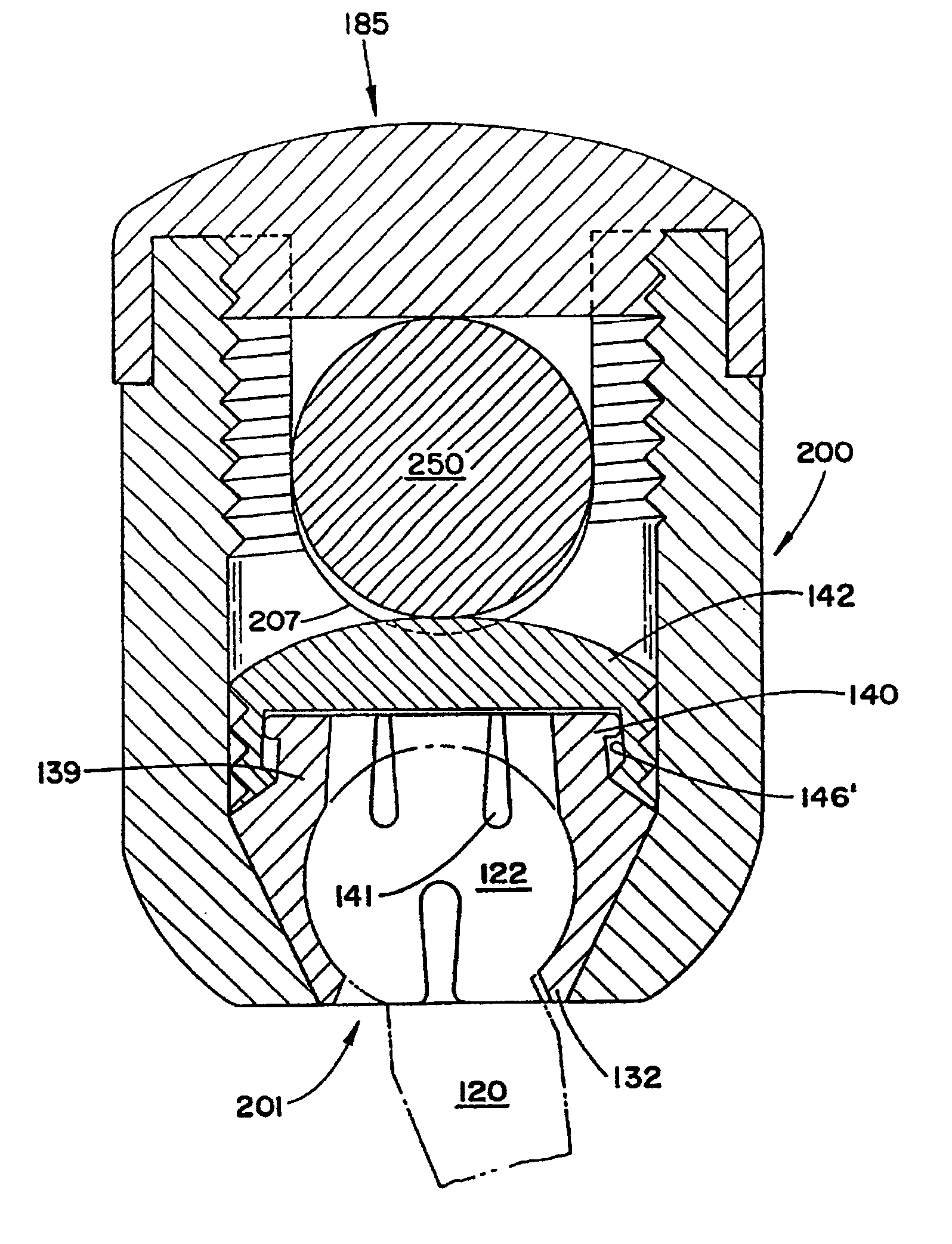

[0038]Referring now to FIG. 4, a side view of the screw portion of the present invention, comprising a curvate head, is shown. The screw 120 comprises a head portion 122, a neck 124, and a shaft 126. In FIG. 4, the shaft 126 is shown as having a tapered shape with a high pitch thread 128. It shall be understood that a variety of shaft designs are interchangeable with the present design. The specific choi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com