Tea kettle

a kettle and tea kettle technology, applied in the field of tea kettles, can solve the problems of inability to form many non-heat-resistant cushioning materials, user hand burns on the handle end, etc., and achieve the effect of enhancing structural and operating advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

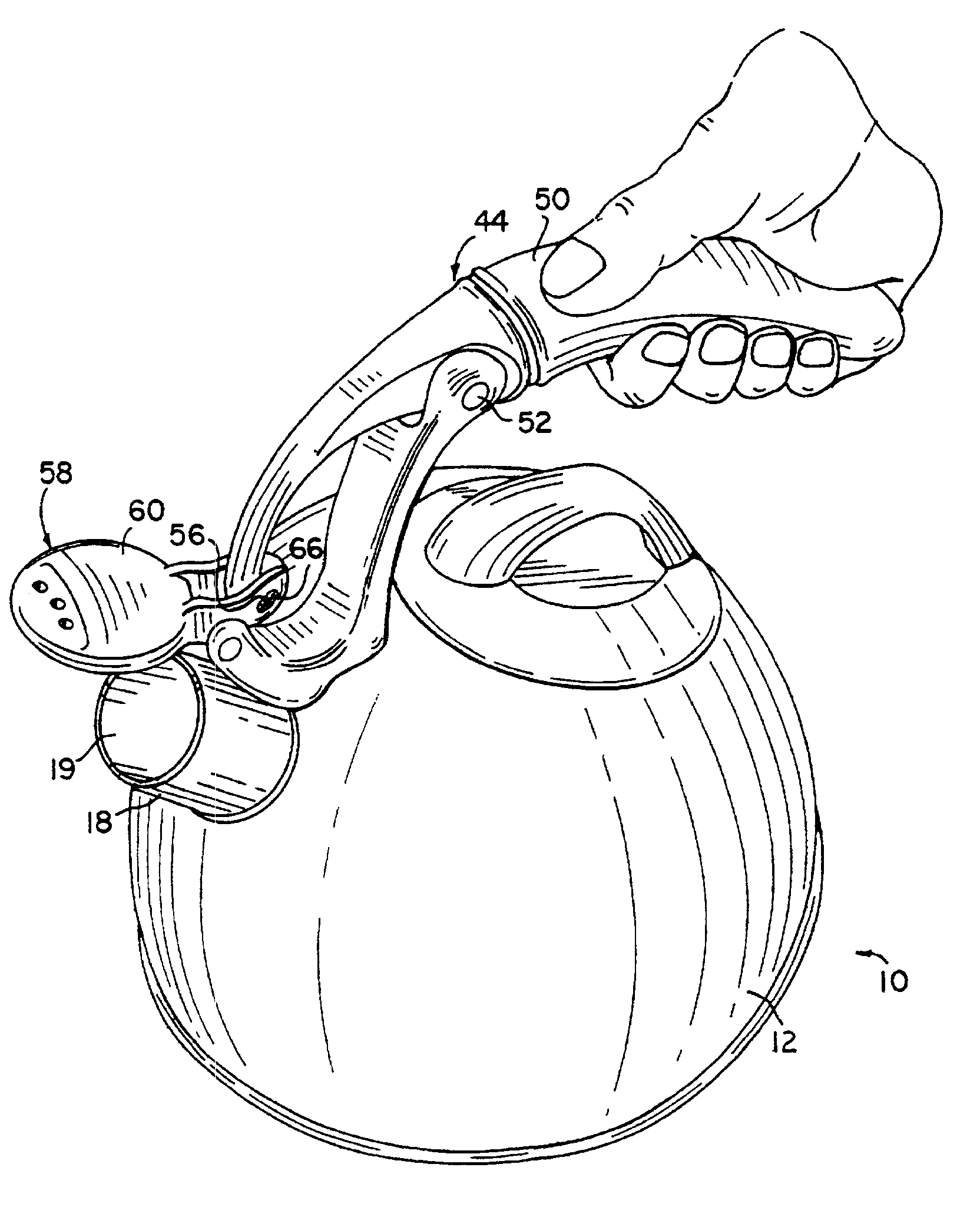

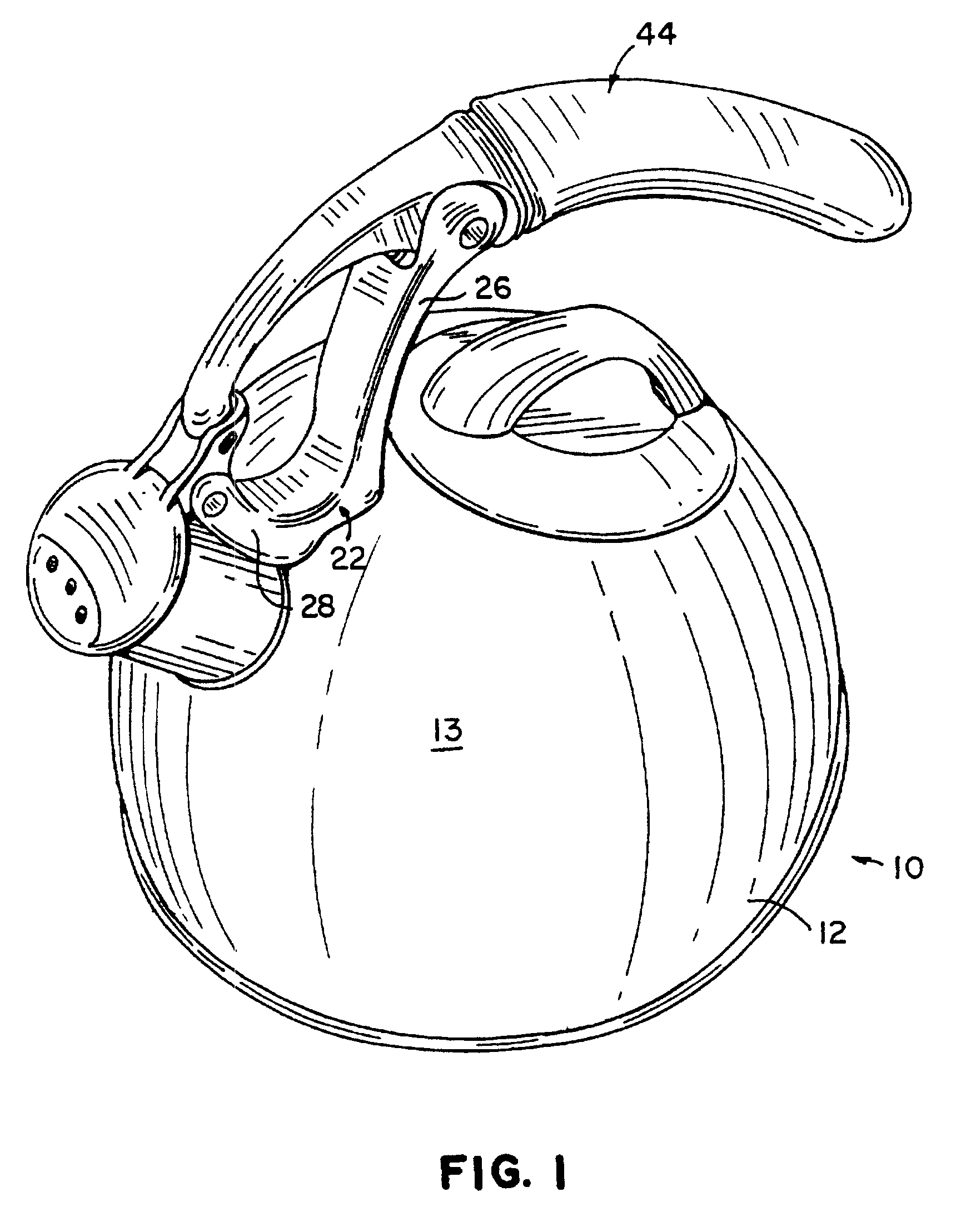

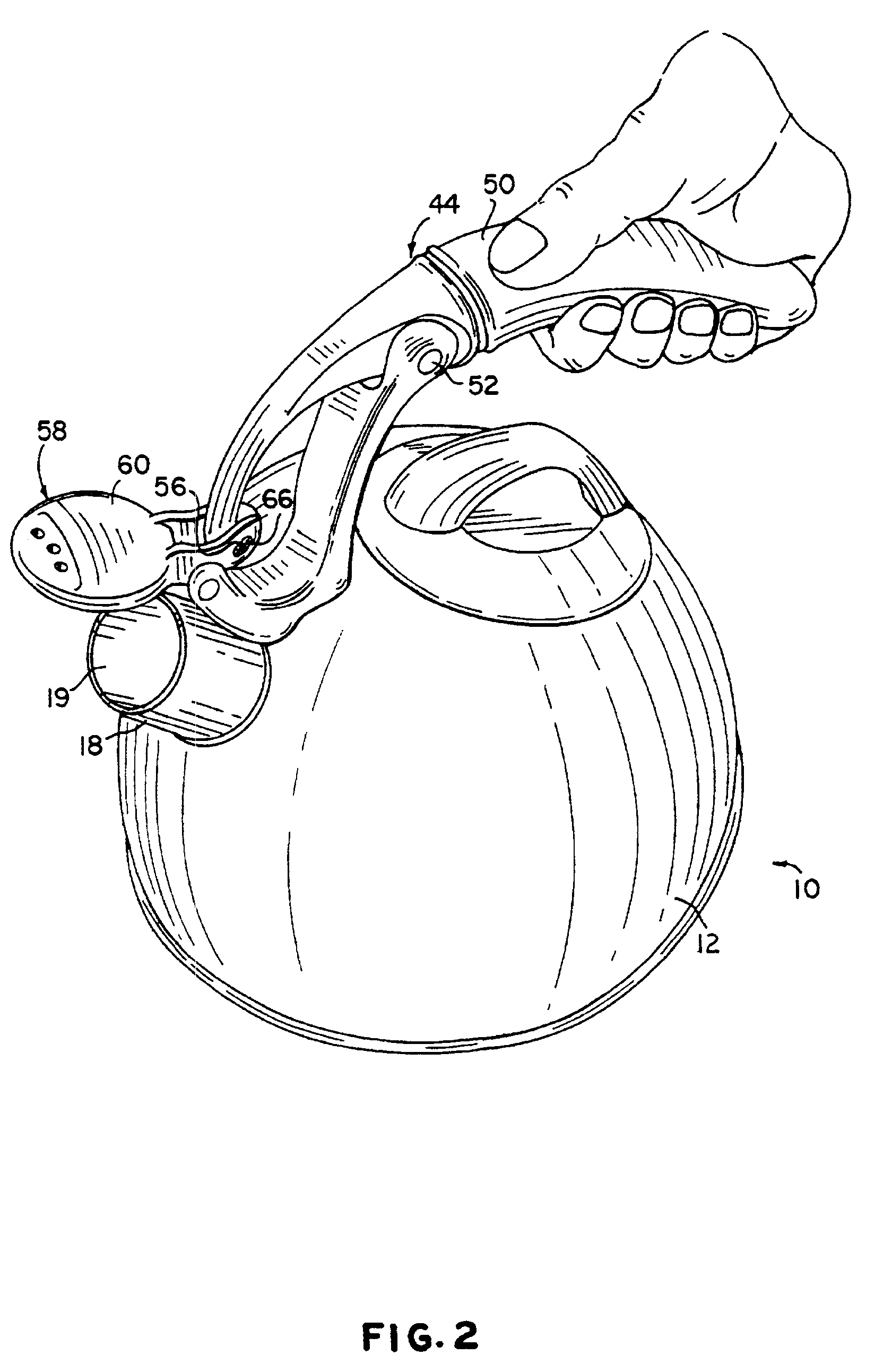

[0023]Referring to the drawings, a tea kettle 10 includes a substantially part-spherical body 12 preferably formed from a metal, such as stainless steel. The body 12 has a central axis “A” (FIG. 6) and defines a storage unit for holding a liquid, such as water, to be heated. The body 12, as seen in FIG. 6, includes a wall 13 defining a spout aperture 14 and a larger second aperture 16, each for accommodating the passage of liquid into and out of the storage unit.

[0024]The kettle 10 also includes a cylindrical spout 18 coupled to the portion of wall 13 defining the spout aperture 14 by welding or the like.

[0025]The kettle 10 also includes a bracket 20 (FIG. 6) coupled to the wall 13 by welding or the like. A support 22 is coupled to the bracket 20 by a pair of screws 24.

[0026]The support 22 includes a first arm 26 having a clevis end 28 with two spaced-apart extensions 30, each having an aperture 32. The support 22 also includes a second arm 34 having a clevis end 36 with two spaced-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com