Tailgate assembly

a tailgate and assembly technology, applied in the field of tailgate assembly, can solve the problems of structural damage to the tailgate assembly, damage to the items and materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

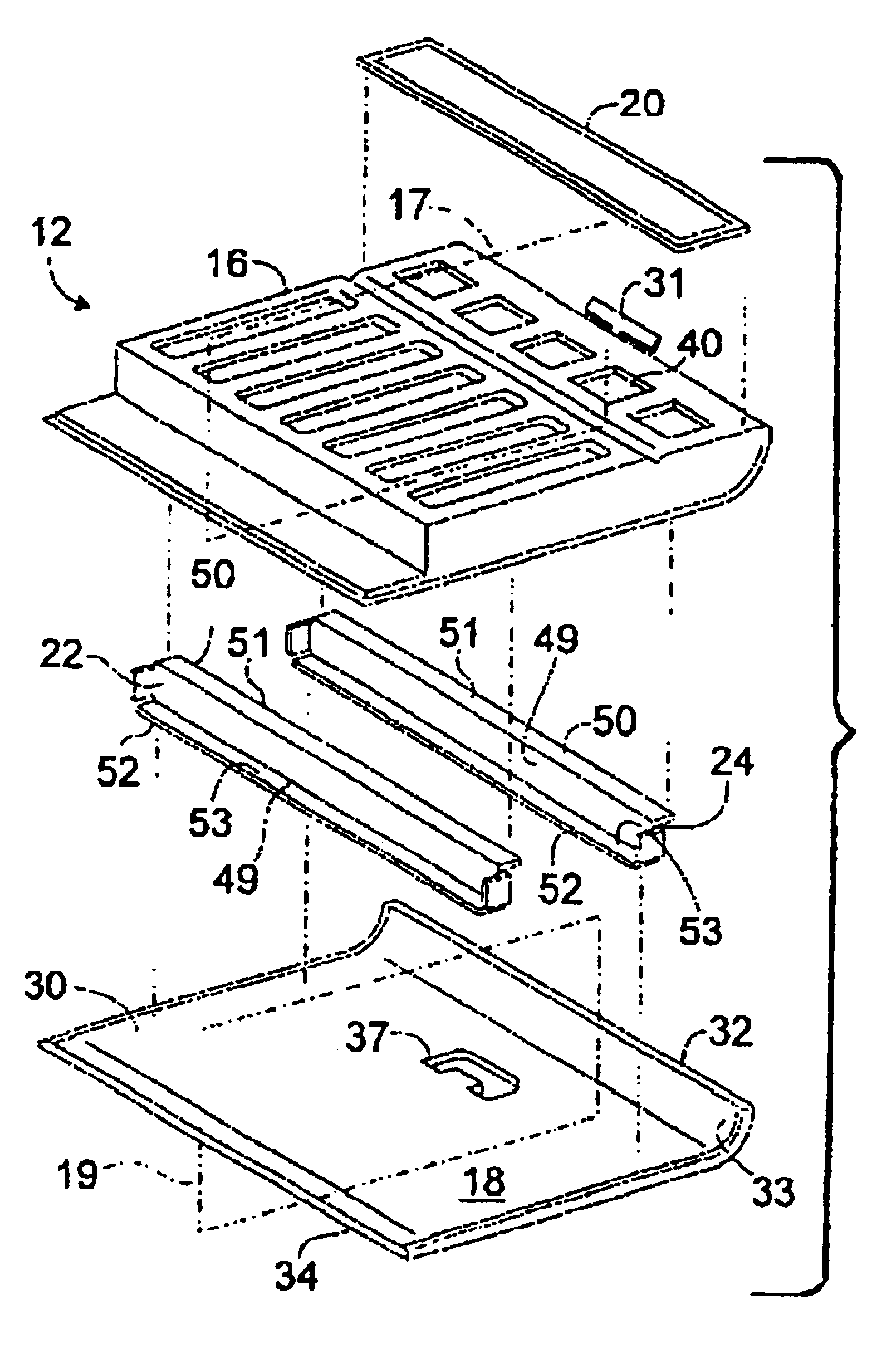

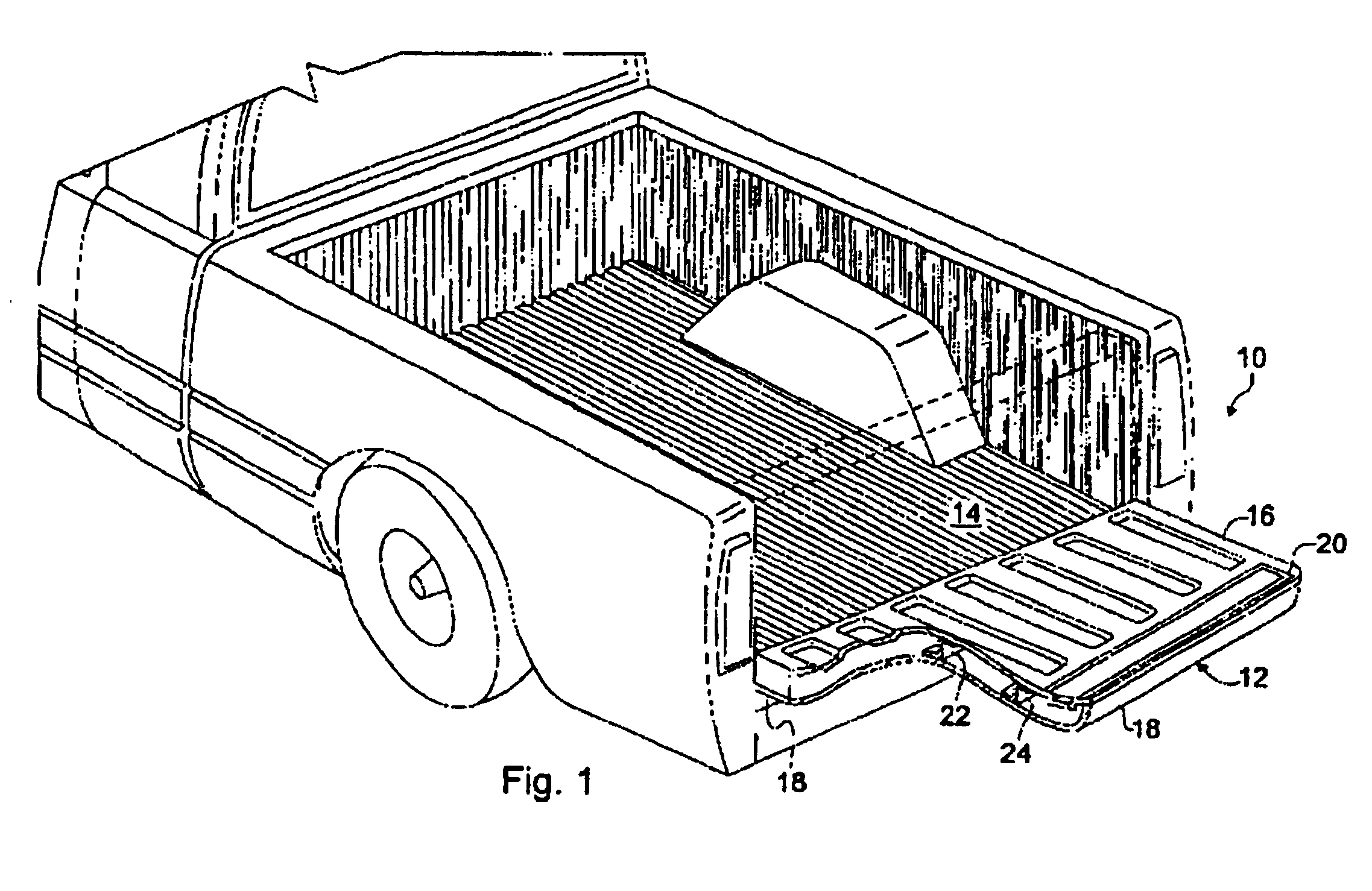

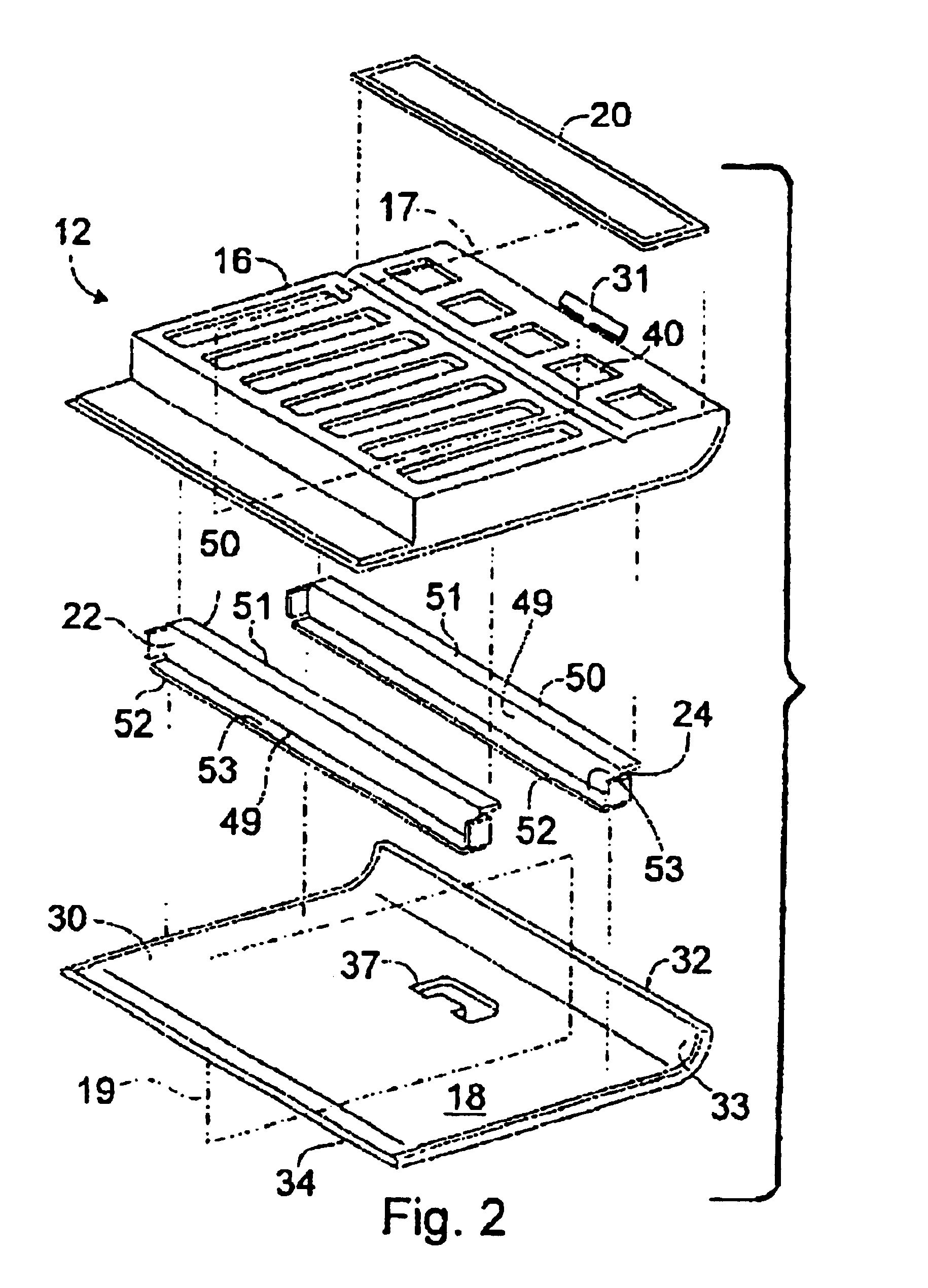

[0016]Referring now to FIG. 1, there is shown a vehicle 10 having a tailgate assembly 12 which is made in accordance with the preferred embodiment of the invention. At the outset, it should be appreciated that the present invention is not limited to a certain vehicle type or configuration. Rather, the present invention may be used with a wide variety of dissimilar vehicles, including but not limited to the vehicle which is shown in FIG. 1, and, as such, the present invention has a wide variety of applications.

[0017]As shown, the vehicle 10 includes a storage bed or compartment 14 and the tailgate assembly 12 is movably coupled to the vehicle 10 by the use of hinges (not shown) or by the use of other devices or mechanisms which allow the tailgate assembly 12 to be selectively moved from a first closed position (shown in phantom in FIG. 1) in which access to the formed storage compartment 14 is restricted, to a second open position (shown in FIG. 1) in which access is readily allowed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com