Monolithic optical compensation device for improved viewing angle in liquid crystal displays

a liquid crystal display and optical compensation technology, applied in static indicating devices, instruments, polarising elements, etc., can solve the problems of loss of contrast ratio, loss of contrast, and amount of light leakage through the display, so as to achieve good contrast, improve the quality of output, and improve the quality of image.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]5.1 Overview of Liquid Crystal Display Structure

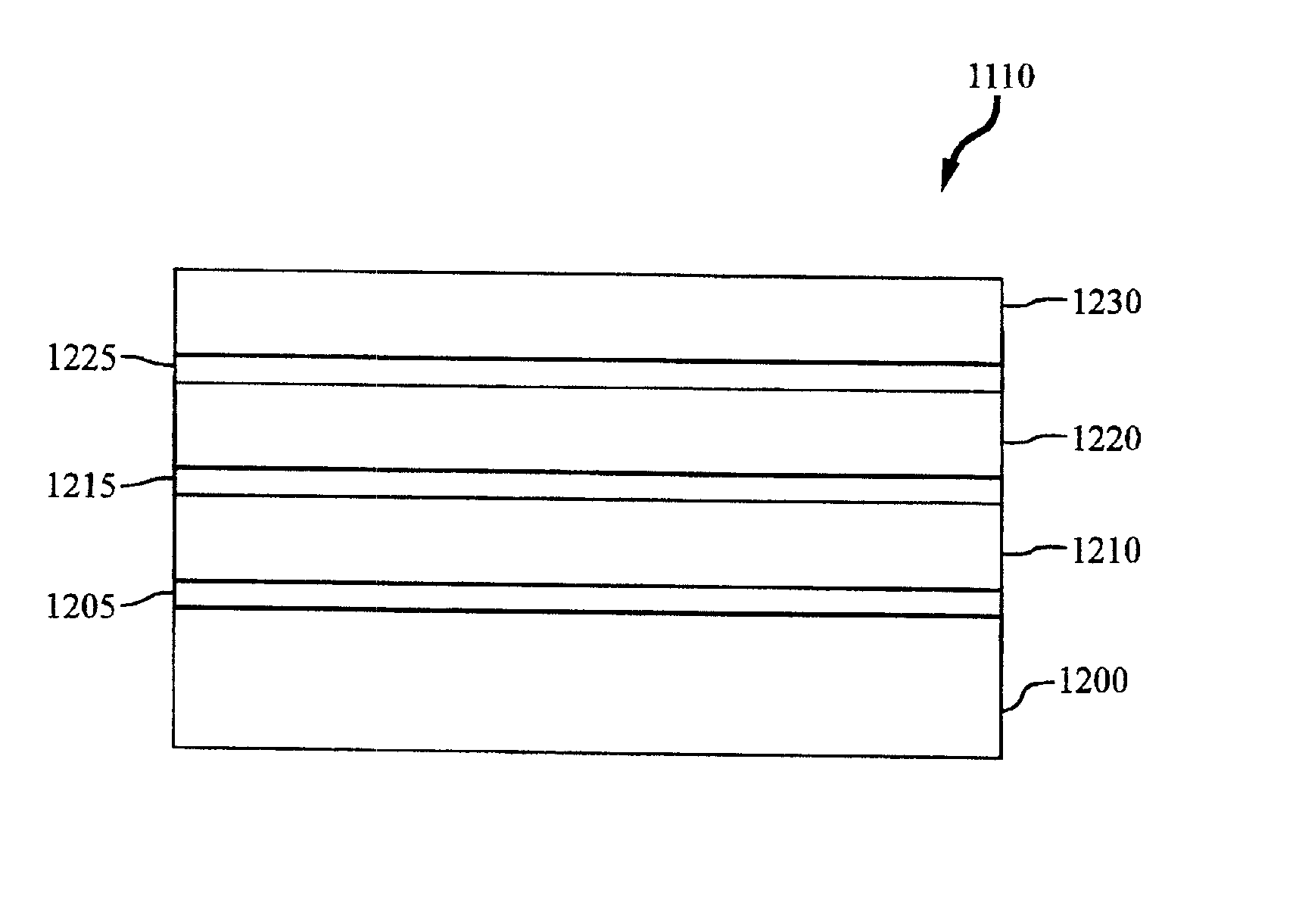

[0013]5.2 Monolithic Compensator Structure

[0014]5.3 Manufacture of the Monolithic Compensator

[0015]5.4 Advantages of the Monolithic Compensator

6. BIBLIOGRAPHY

7. CLAIMS

8. ABSTRACT

2. BACKGROUND OF THE INVENTION

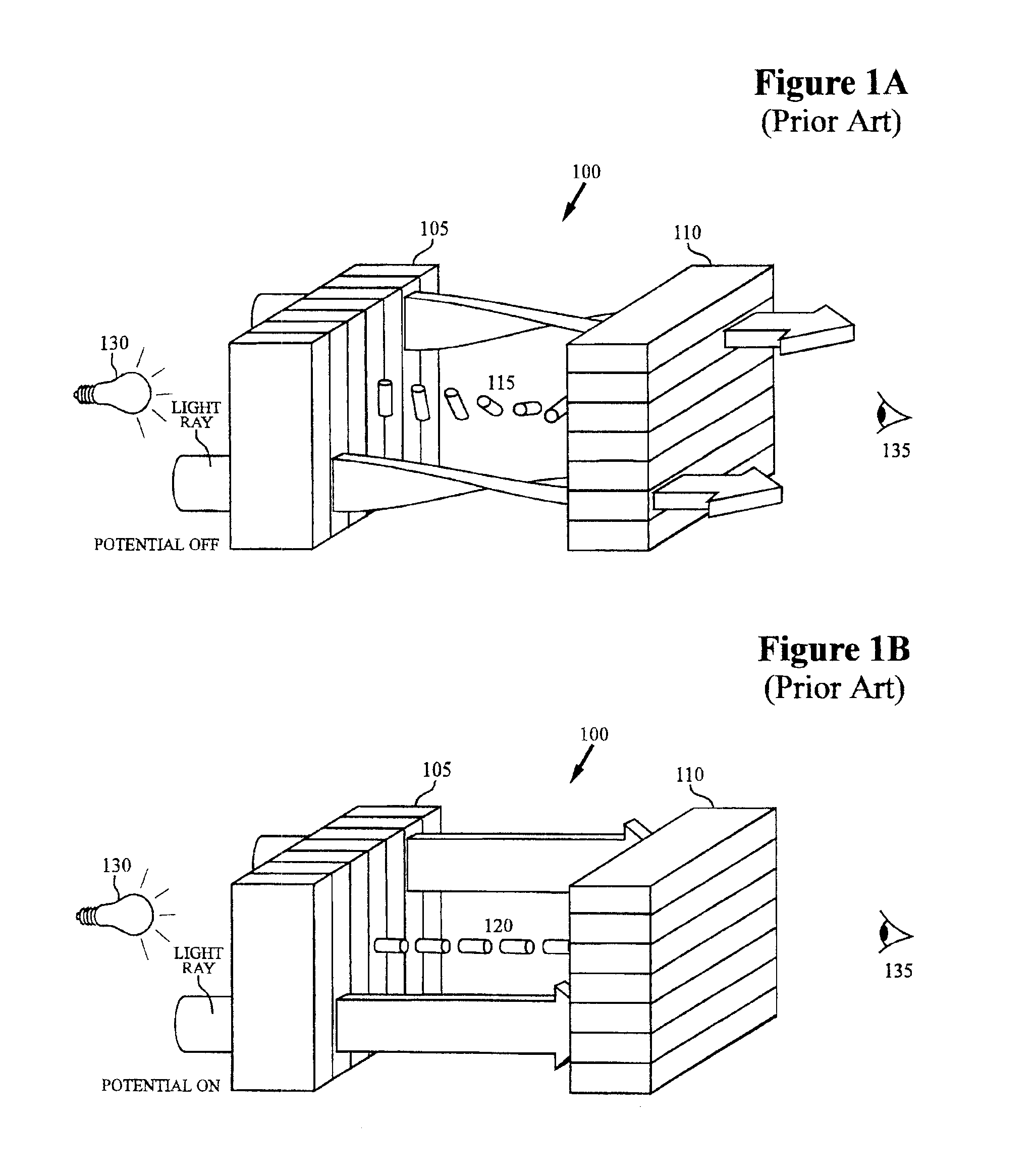

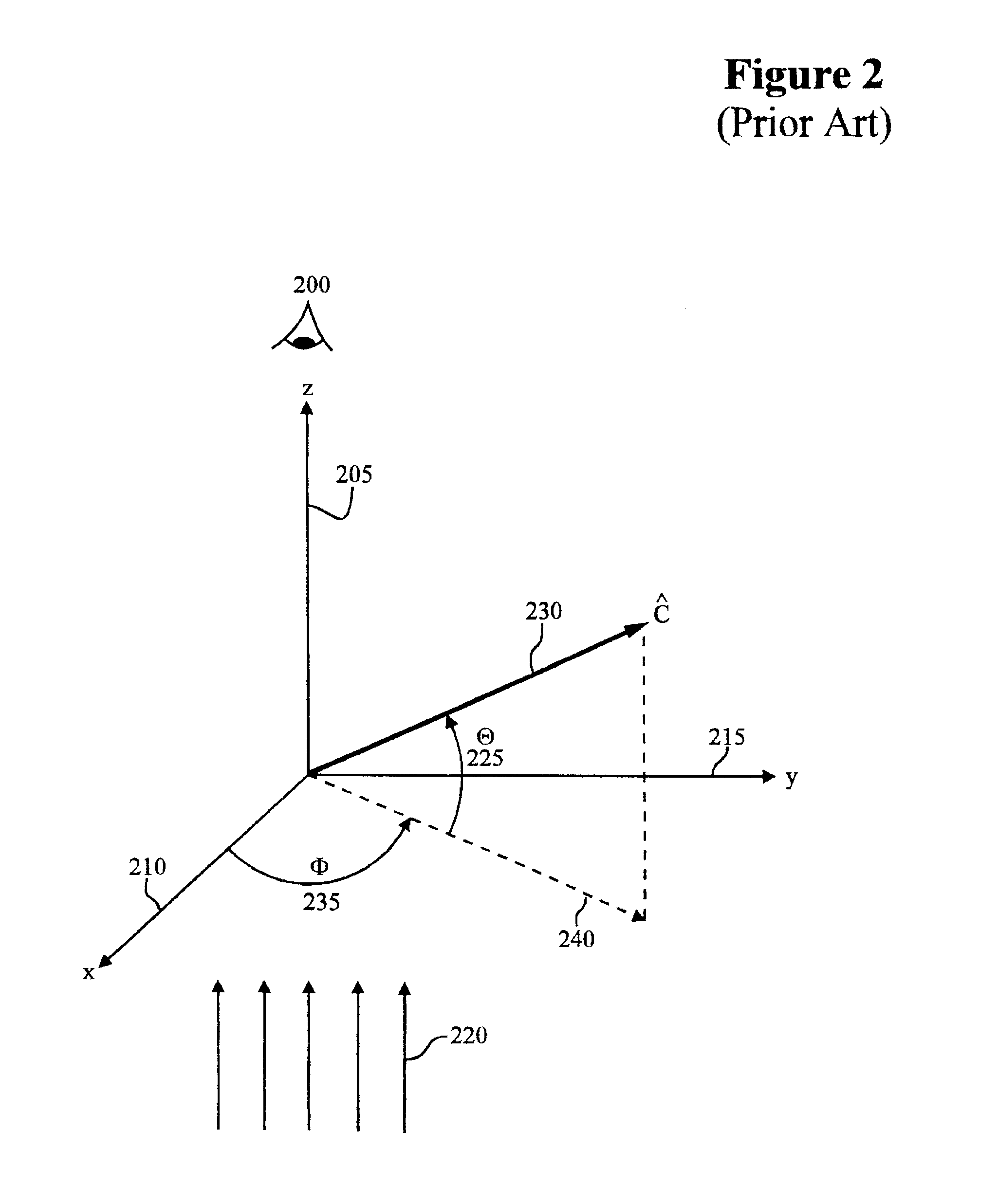

[0016]This invention is concerned with the design of liquid crystal displays (LCDs) and, more particularly, with techniques for maximizing the field of view of such displays by maintaining a high contrast ratio and minimal variance in relative gray levels over a wide range of viewing angles. These goals are achieved through the fabrication and manufacture of LCDs using a monolithic compensator device.

[0017]2.1 LCD Technology Overview

[0018]Liquid crystals are useful for electronic displays because polarized light traveling through a liquid crystal layer is affected by the layer's birefringence, which can be changed by the application of a voltage across the layer. By using this effect, the transmission or reflection of light f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com