Liquid crystal display formed by a plurality of non-electrically interconnected liquid crystal display panels

a liquid crystal display and panel technology, applied in static indicating devices, non-linear optics, instruments, etc., can solve the problems of difficult to see the joints between the liquid crystal panels, and achieve the effects of eliminating the problems, low power consumption, and easy to s

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

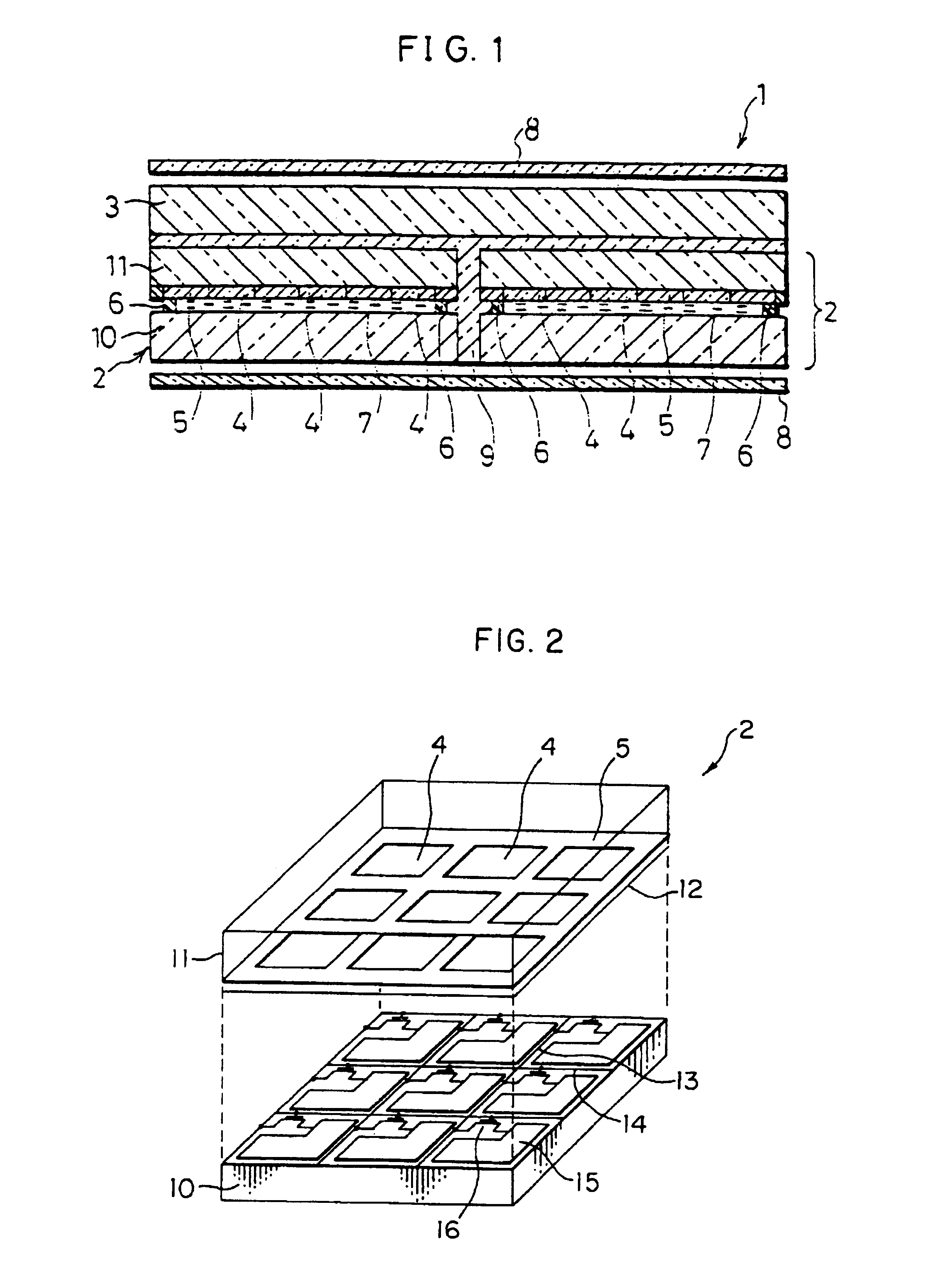

[0055]An embodiment of the present invention will be explained in the following while referring to FIGS. 1 through 4.

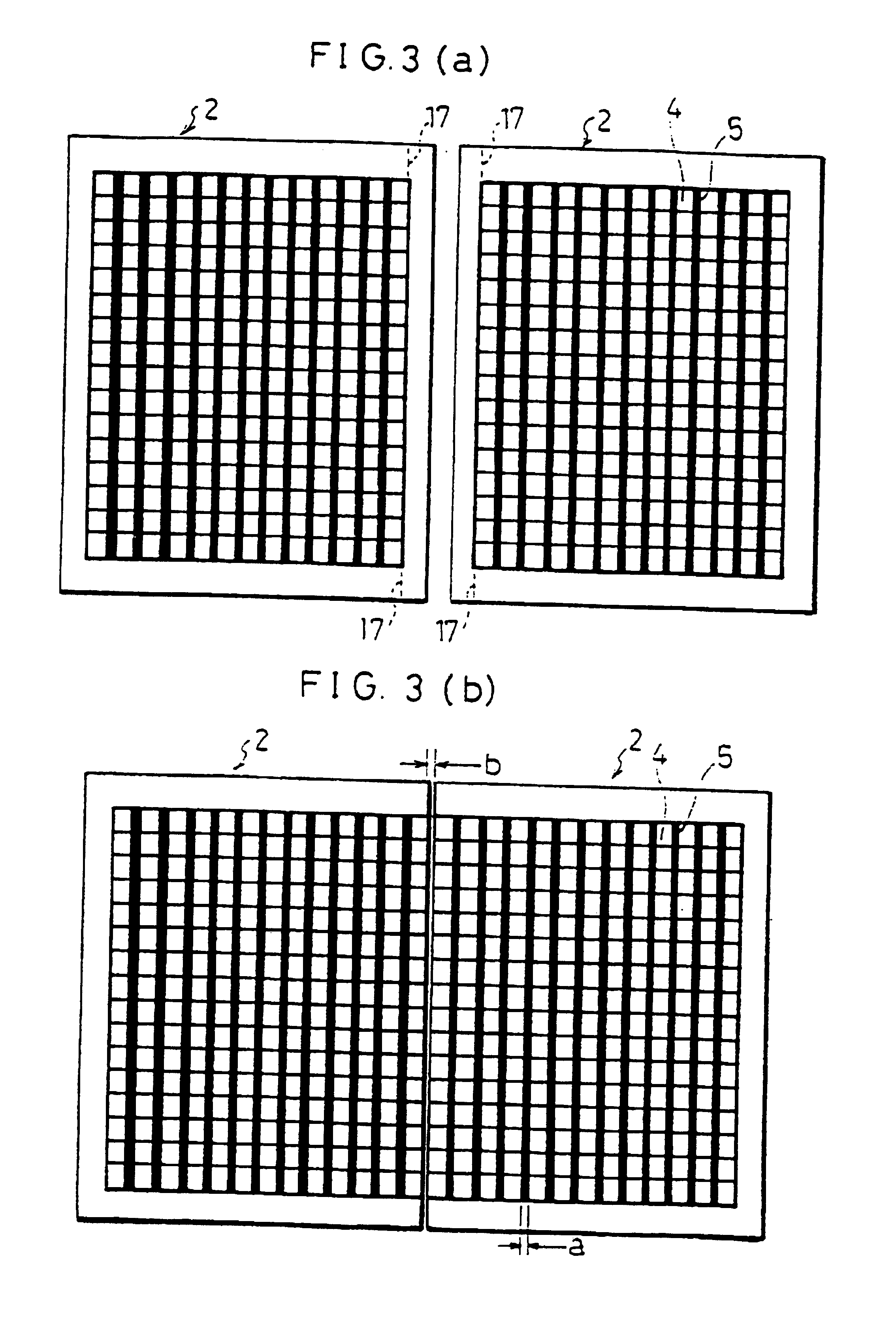

[0056]As shown in FIG. 1, a liquid crystal display 1 of the first embodiment is of the direct sight type. The liquid crystal display 1 comprises a main body and two polarizing plates 8 (polarizing elements). The main body includes a plurality of liquid crystal panels 2 of an active matrix type placed on a single surface of a large substrate 3, and a back light such as a cold cathode tube on the rear surface (lower in the drawing) of the liquid crystal panels 2. The polarizing plates 8 will be described more in detail below. A driver which controls an image signal and the back light are not shown in the drawing. The viewer can see the image data inputted into the liquid crystal panels 2 when the liquid crystal panels 2 modulate the light from the back light in accordance with the input image data.

[0057]As shown in FIG. 2, each liquid crystal panel 2 is of the same stru...

second embodiment

[0089]Another embodiment of the present invention will be explained while referring to FIGS. 1 through 5. Hereinafter, like components are labeled with like numerals with respect to the first embodiment and the description of these components is omitted for the explanation's convenience.

[0090]As shown in FIG. 5, a liquid crystal display 20 of the second embodiment comprises a plurality of liquid crystal panels 2 sandwiched by two large substrate, the large substrate 3 (base) and a large substrate 21 (base). The liquid crystal panels 2 of the second embodiment are of the same structure as those of the first embodiment. The driver controlling the image signal and the back light are not shown in the drawing.

[0091]The liquid crystal display 20 differs from the liquid crystal display 1 of the first embodiment in that the large substrate 21 is additionally laminated to the liquid crystal panels 2 which have already laminated to the single plane of the large substrate 3. The refraction fac...

third embodiment

[0097]Another embodiment of the present invention will be explained while referring to FIGS. 6 through 9. Hereinafter, like components are labeled with like numerals with respect to the above embodiments and the description of these components is omitted for the explanation's convenience.

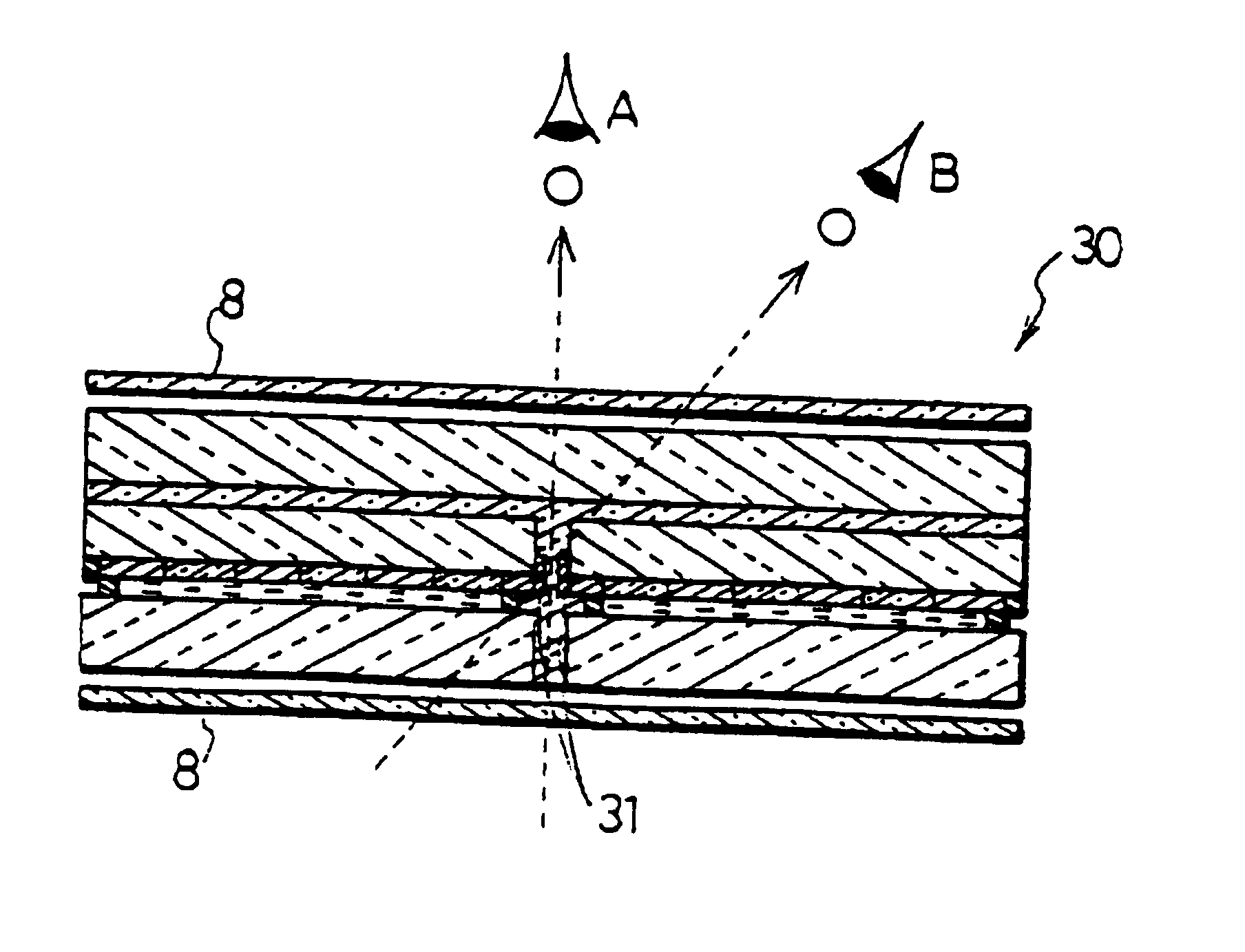

[0098]As shown in FIG. 6, unlike the liquid crystal display 1 of the first embodiment, a liquid crystal display 30 of the third embodiment includes a second photo-blocking films 31 that cover the end surfaces of the connected part side of the liquid crystal panels 2 (the end surface of the glass substrate 11) along a longitudinal direction in a predetermined width. Each second photo-blocking film 31 is perpendicular with respect to the black matrix 5 and extends in a constant width toward the front surfaces of the liquid crystal panels 2. The second photo-blocking films 31 are made of, for example, a black resin made by dispersing a pigment or semi-conducting particulates (for example, carbon partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com