Acetabular component with improved liner seal and lock

a technology of acetabular components and seals, applied in the field of acetabular components with improved liner seals and locks, can solve the problems of damage to the bone into which the acetabular shell is inserted, debris can be generated, damage to the bone, etc., and achieve the effect of preventing the migration of poly debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

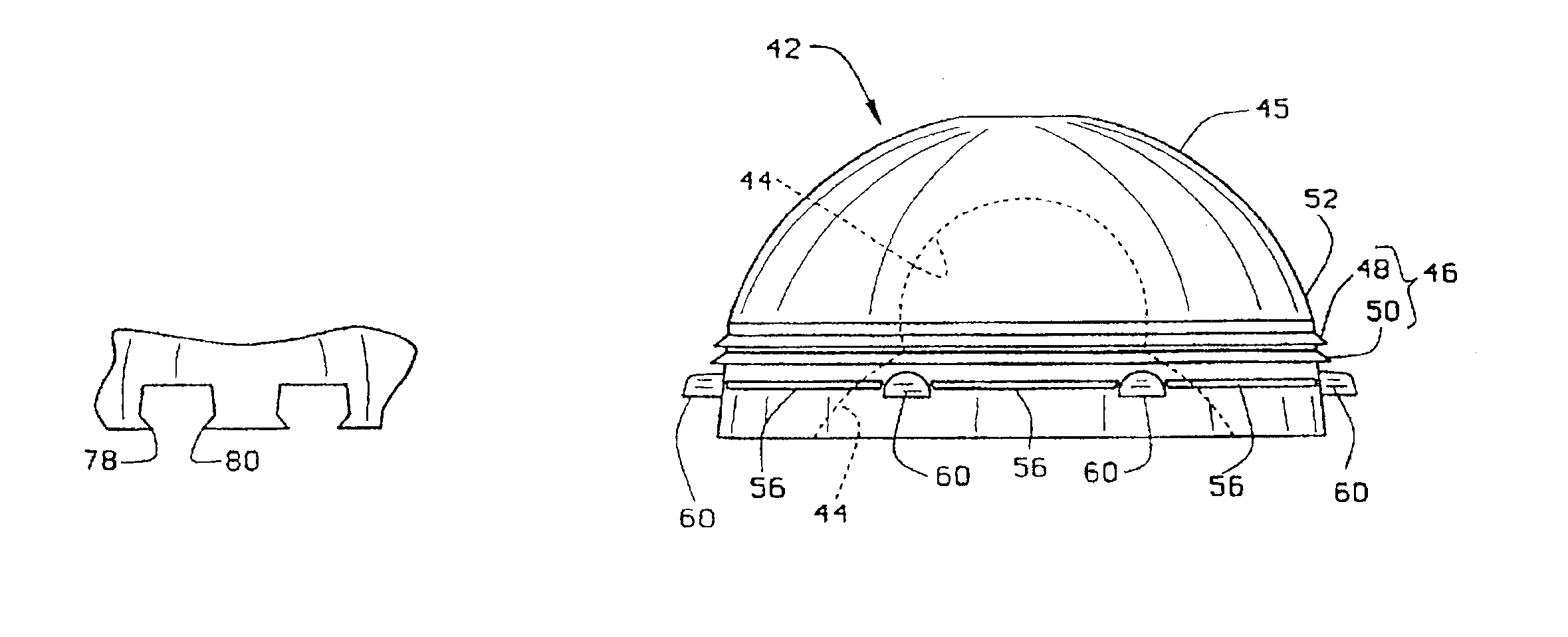

[0019]The prosthesis component of the present invention is an acetabular component for a hip replacement system. FIG. 1 includes an acetabular shell 32 with a plurality of screw holes 34 and a plurality of peripheral notches 36. The acetabular shell 32 has an inner surface 38 and an outer surface 40. The outer surface 40 is generally hemispherical, and is contoured to closely match the shape of a hemispherically reamed acetabular, or cotyloid cavity, into which the shell 32 is to be implanted. The inner surface 38 of the shell 32 is also generally hemispherical, except near its peripheral edge which is relatively flat, and smooth as best seen in FIG. 2.

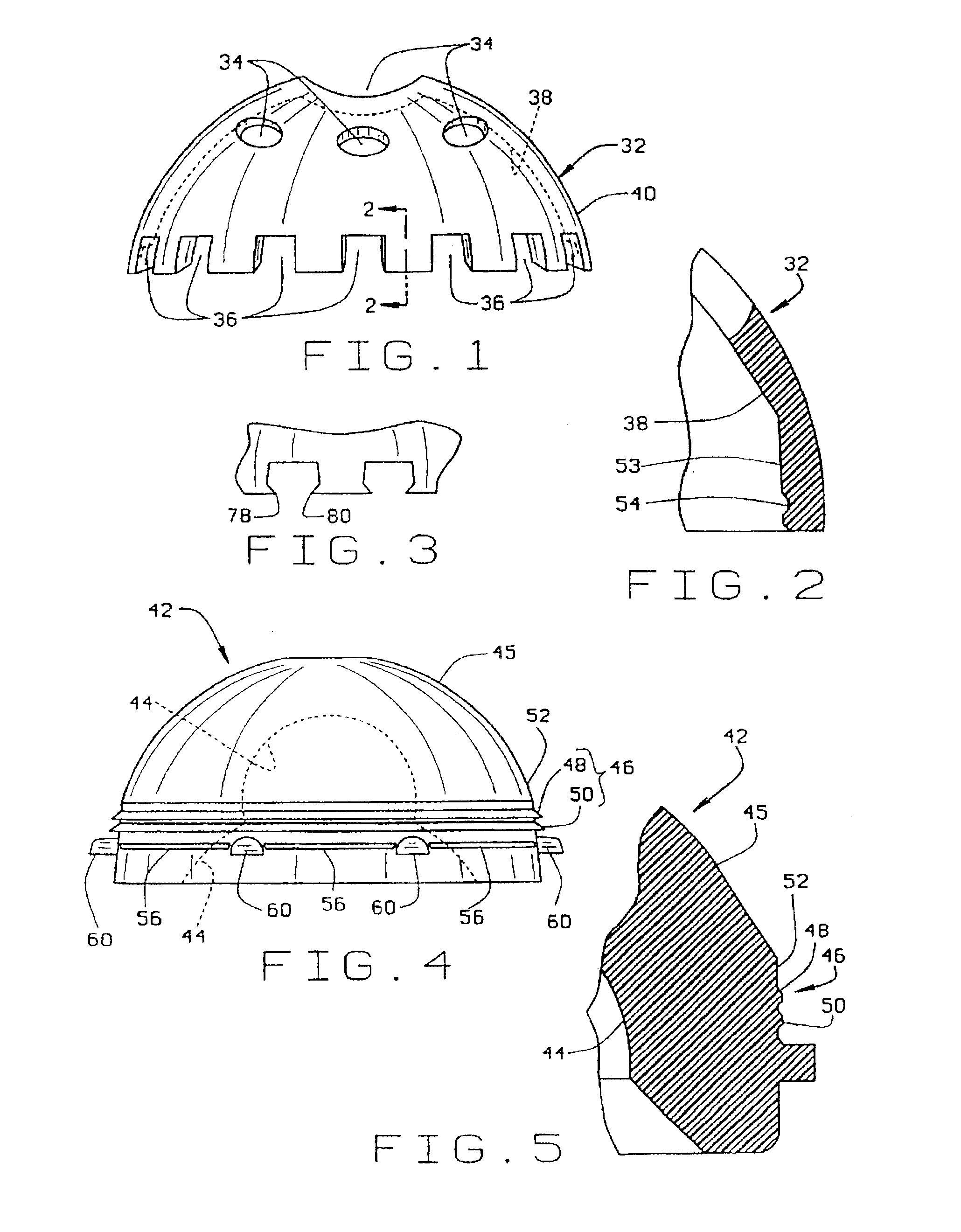

[0020]The liner 42, as shown in FIGS. 4 and 5, is designed to be inserted into the acetabular shell 32. The liner has an inner surface 44 that interfaces with a femoral head component (not shown) of the hip replacement system. The liner is constructed from ultra high molecular weight polyethylene or other similar material, and has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com