Multi-cylinder diesel engine with variably actuated valves

a multi-cylinder diesel engine and valve technology, applied in the direction of valve drives, non-mechanical valves, electrical control, etc., can solve the problem that the internal egr can only be realized in a limited measure, and achieve the effect of reducing harmful exhaust emissions, improving performance and/or consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

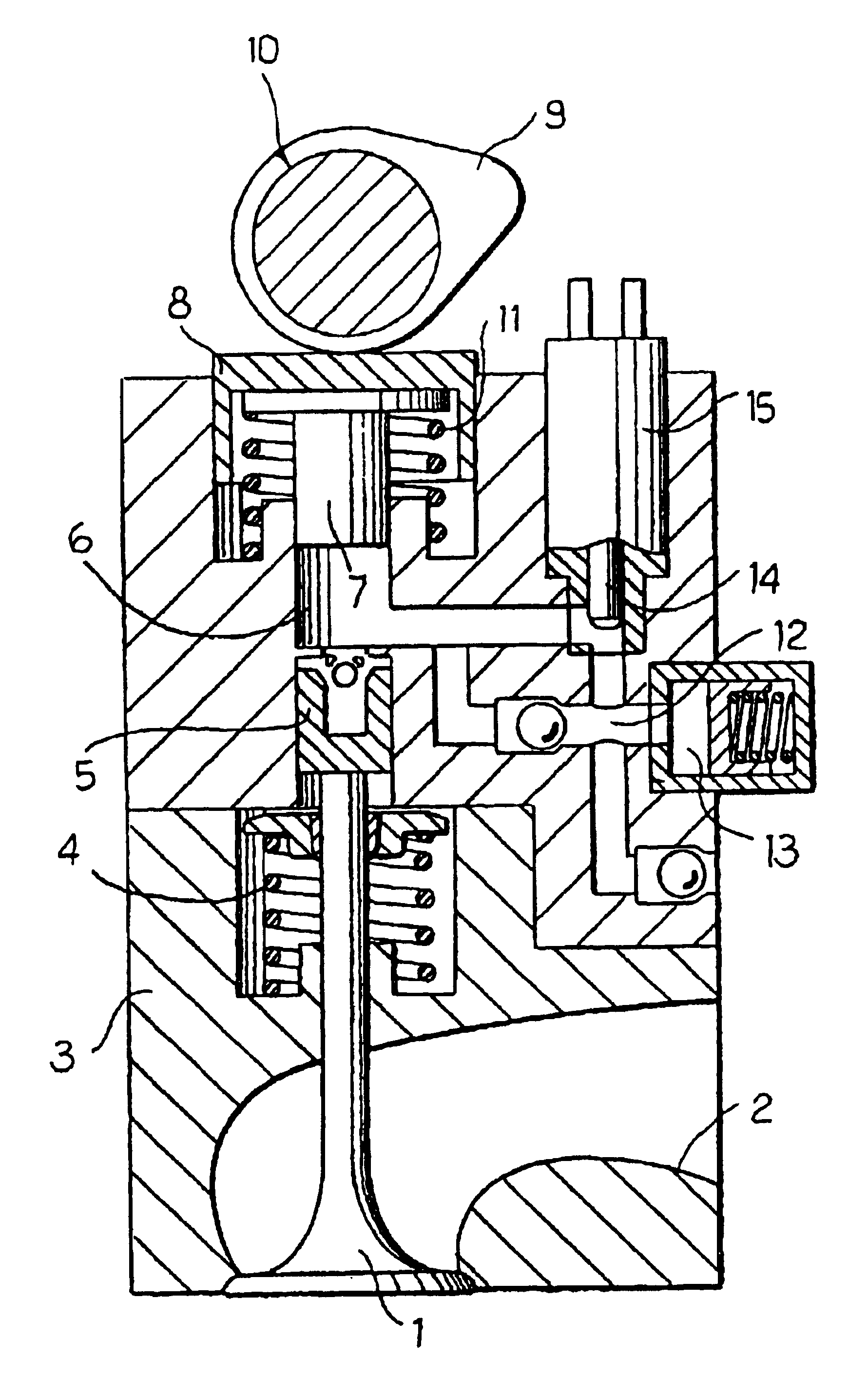

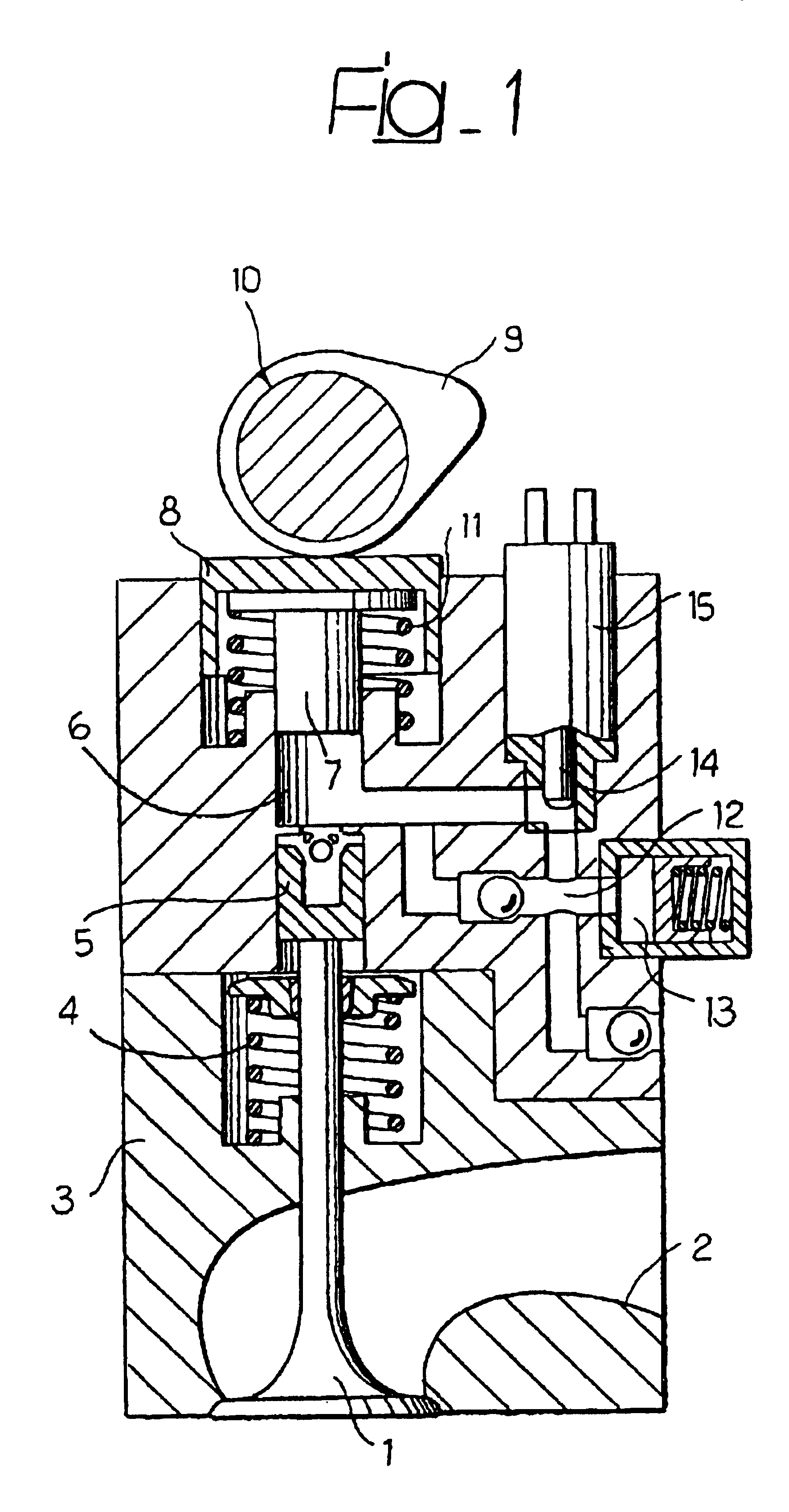

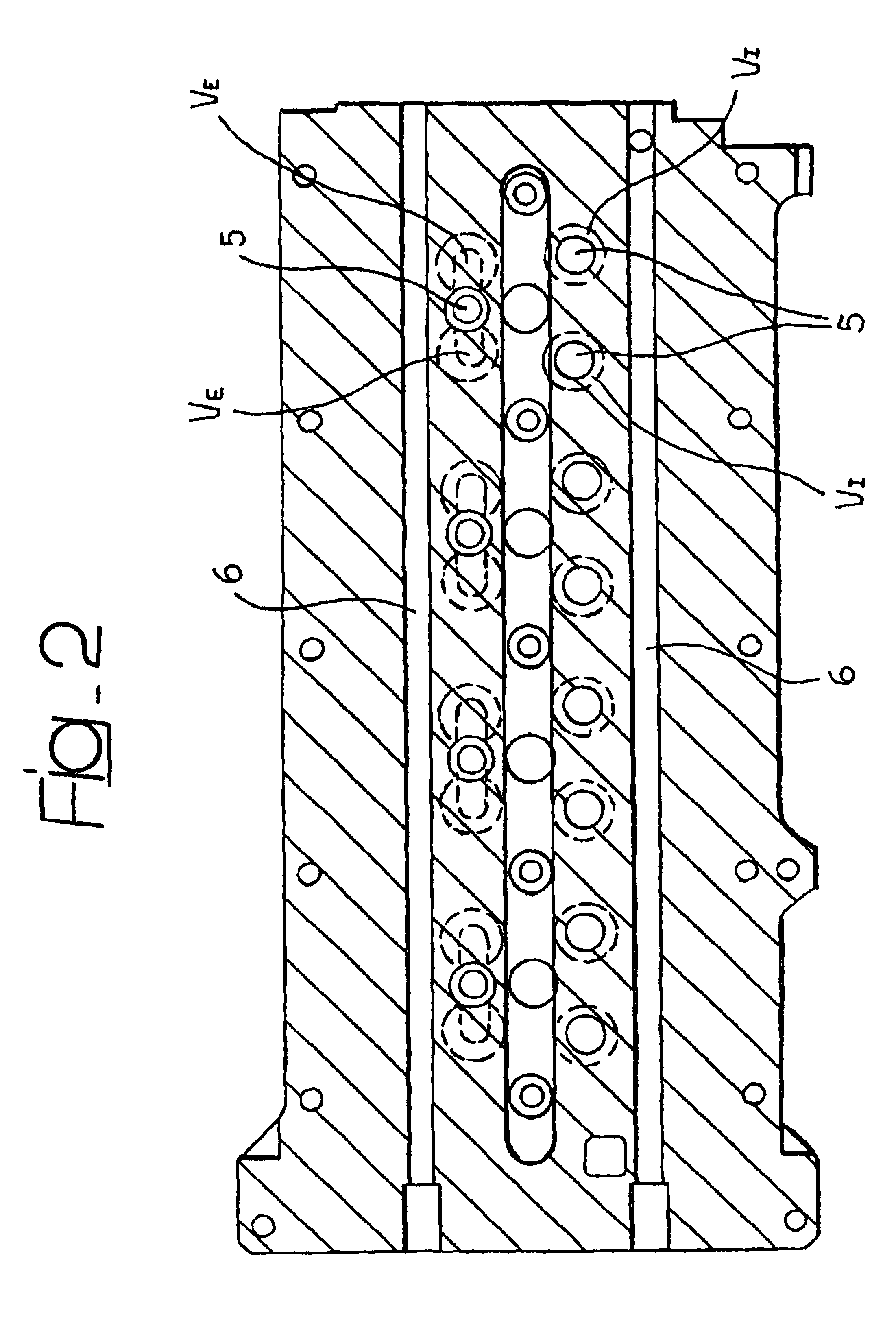

[0031]FIG. 1 schematically illustrates the principle of operation of a variable valve actuation system in an internal combustion engine. Reference number 1 indicates the valve (which can be either an inlet valve or an exhaust valve) as a whole, associated with a respective port 2 (inlet or exhaust) formed inside the cylinder head 3 of an internal combustion engine. The valve 1 is drawn towards its closed position (upwards with reference to FIG. 1) by a spring 4, while it is forced to open by a piston 5 acting on the upper end of the valve stem. The piston 5 is in turn controlled via oil under pressure that is present in the chamber 6, by a piston 7 that supports a spring cup 8 cooperating with a cam 9 on a camshaft 10. The spring cup 8 is held in sliding contact with the cam 9 by a spring 11. The pressure chamber 6 can be connected to a port 12, which in turn communicates with a pressure accumulator 13, via the shutter 14 of a solenoid valve 15 that is commanded by the electronic me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com