Multilayer sole for sport shoes

a technology of sport shoes and soles, applied in the direction of uppers, bootlegs, apparel, etc., can solve the problems of affecting the efficiency of the second layer, affecting the comfort layer, and excessive flexural rigidity of the sole, so as to improve the effect of the outer or contact layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

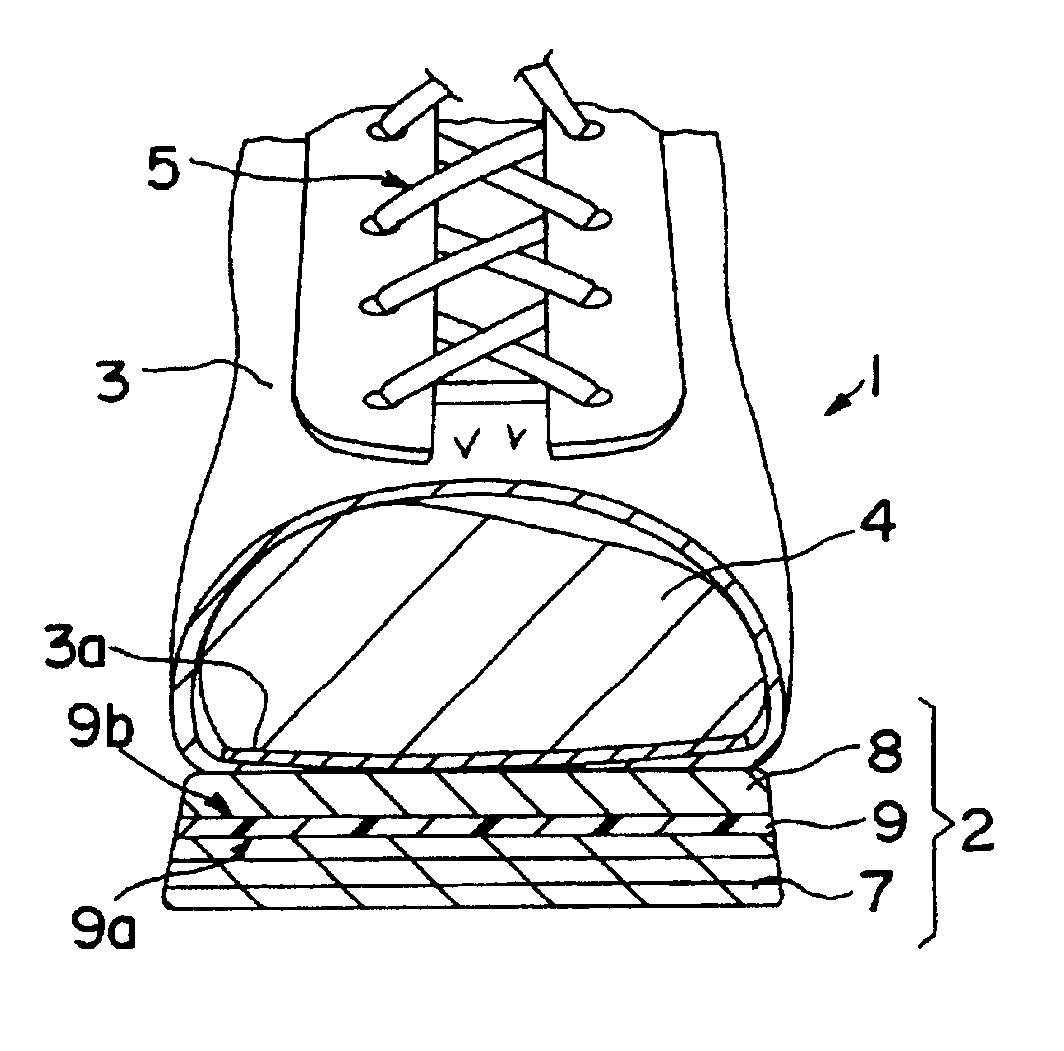

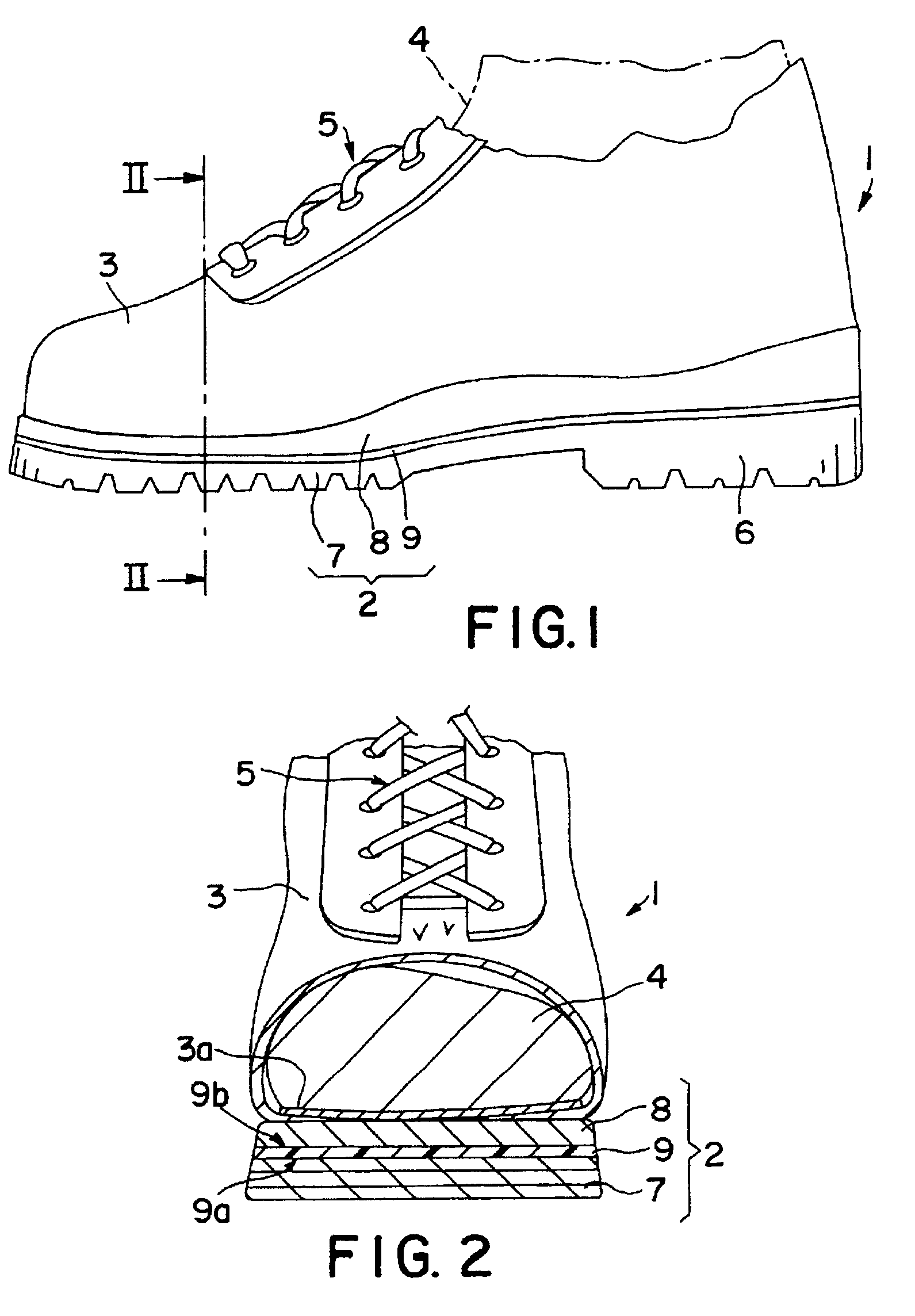

[0057]The sport shoe 1 shown in a first embodiment in FIGS. 1 and 2 comprises an outer sole 2, on which an upper 3 is mounted, this upper incorporating conventionally an opening allowing insertion of the foot 4, this opening being fitted with a closure system 5, e.g., a lacing system. The rear part of the sole 2 comprises a heel 6.

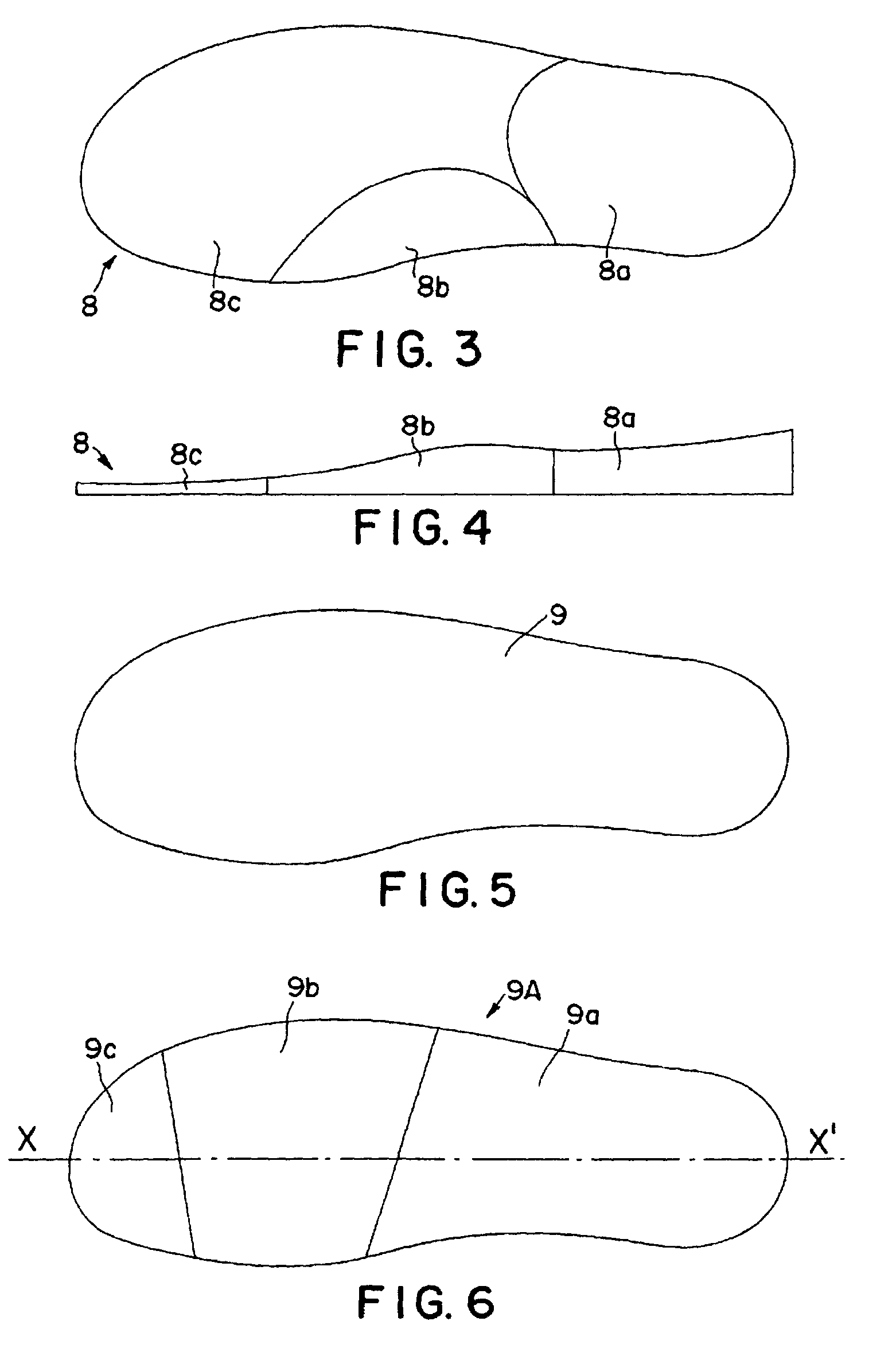

[0058]The sole 2 has a laminated profile, as shown in FIG. 2, comprising several layers fulfilling distinct functions.

[0059]According to the invention and to the present embodiment, the sole 2 comprises three layers 7, 8, 9 arranged in the following manner:[0060]an outer, or contact, layer 7 with properties of flexibility, gripping, and abrasion-resistance which allow, simultaneously, good foot extension, good ground traction, and a high level of resistance to wear;[0061]an upper or comfort layer 8 placed directly beneath the upper, 3, and thus the foot 4, which has elastic shock-absorption properties and which is assembled directly on a surface of the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com