Deep sewage treatment method and apparatus

A sewage treatment method and sewage treatment device technology, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex maintenance and management of facilities and high cost, and achieve easy Management, easy equipment, cost effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

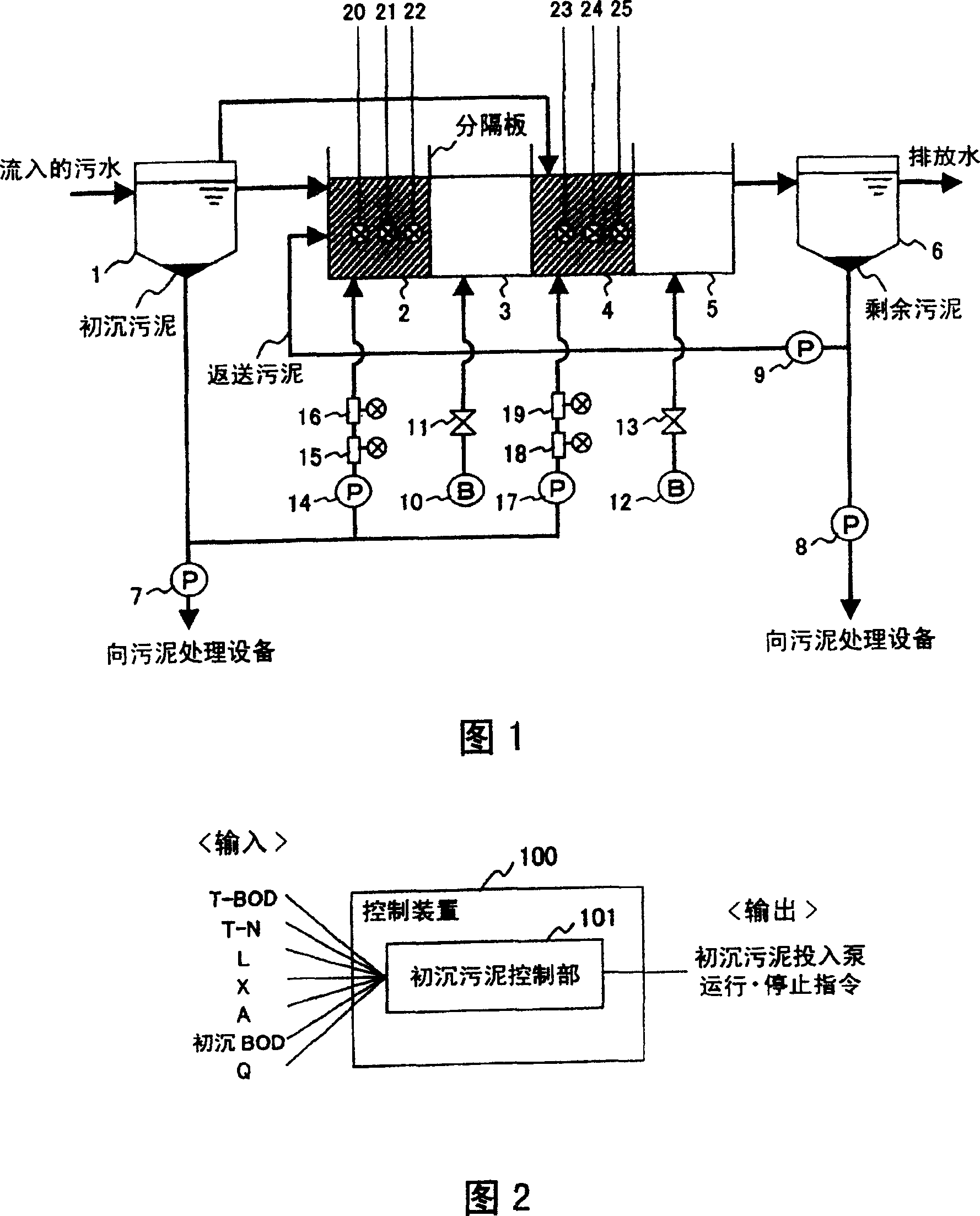

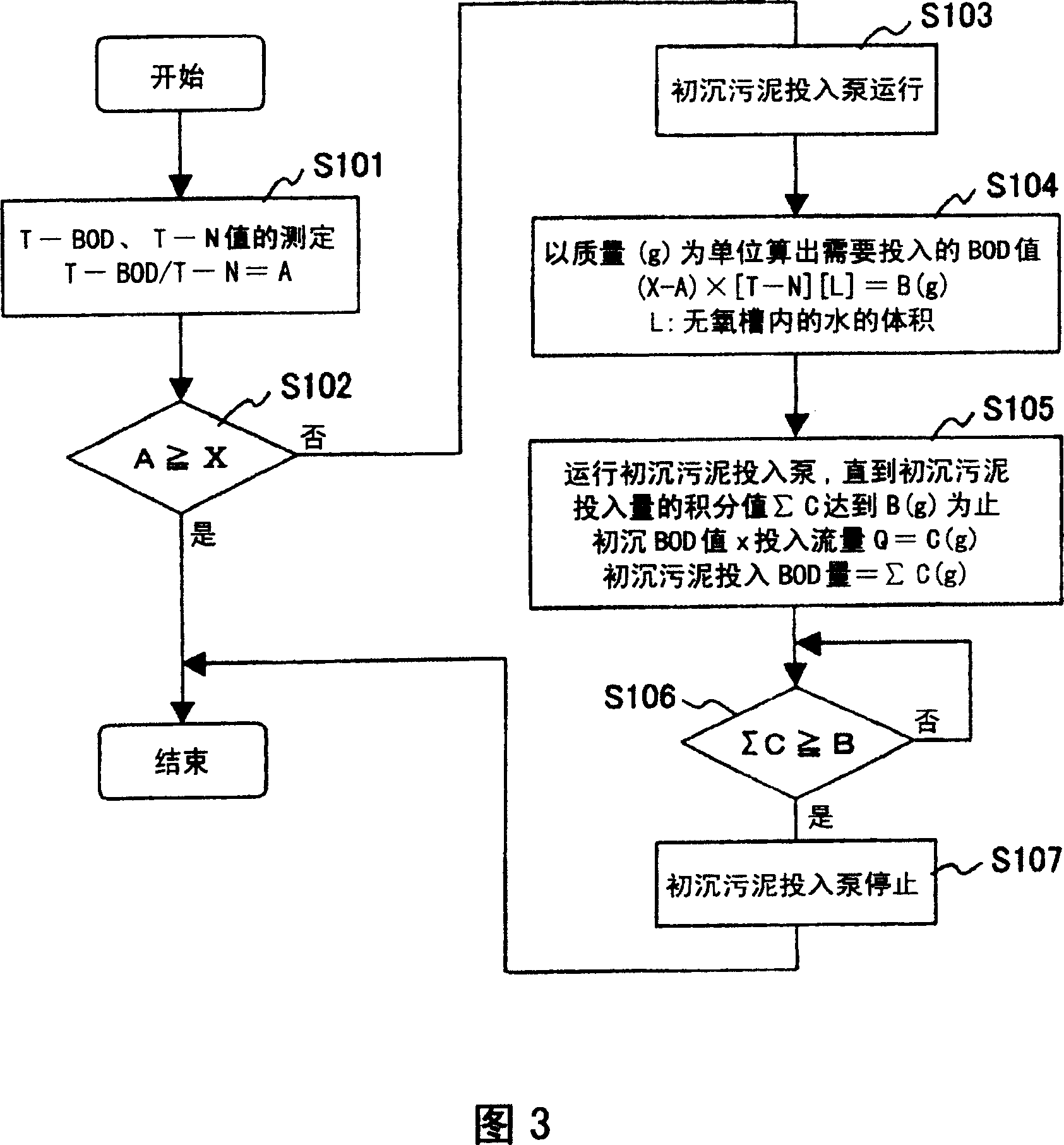

[0015] Next, an embodiment of the present invention will be described with reference to the drawings. Figure 1 shows the equipment flow of the sewage treatment plant through the multi-stage nitrification and denitrification method of water inflow in stages. This sewage treatment plant is composed of initial sedimentation tank 1, reaction tank (anaerobic tank: 2, 4, aerobic tank: 3, 5), final sedimentation tank 6, primary sludge pump 7, return sludge pump 9, Excess sludge extraction pump 8, air blower 10,12, discharge valve 11,13 constitute.

[0016] The sewage flowing into the initial sedimentation tank 1 is separated from solid and liquid due to physical effects, and the settled sludge is drawn into the sludge treatment equipment by the primary sludge pump 7, while the above clarified liquid will pass through the anaerobic tank 2 and the anaerobic tank. The piping of the oxygen tank 4 is provided to each anaerobic tank.

[0017] In the anaerobic tank 2, the nitrate nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com