Complete equipment for processing regenerative asphalt concrete

A technology of recycled asphalt and complete sets of equipment, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of difficult to meet the requirements of high-grade road surface, cannot use high-grade road surface, and the quality of road surface is not very ideal, so as to achieve perfect dust removal facilities , reduce land and its pollution to the environment, and alleviate the contradiction between supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

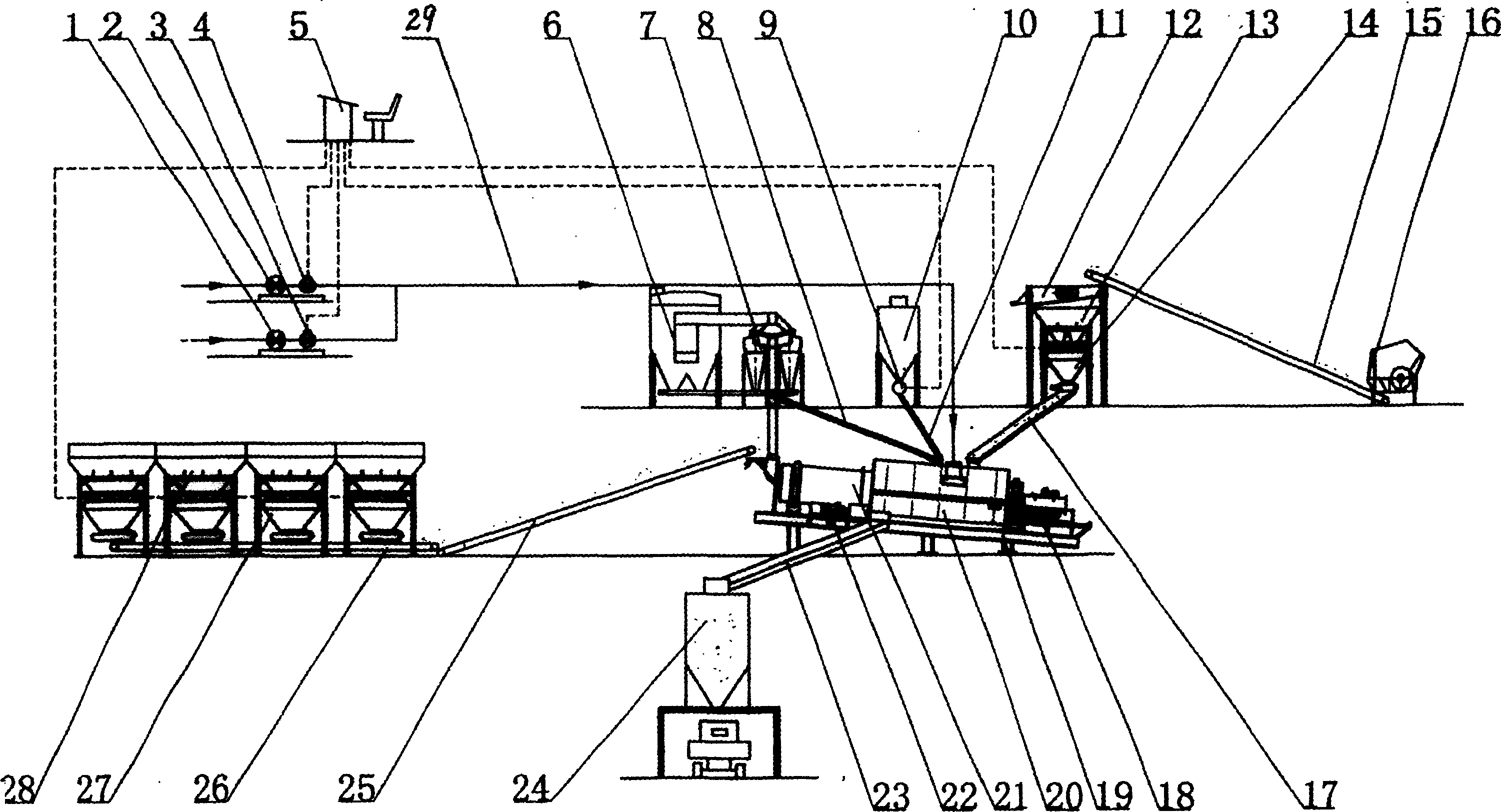

[0020] The invention mainly consists of a continuous double-drum recycled asphalt mixer, a new aggregate supply system, an old asphalt mixture supply system, a new asphalt and waste asphalt regeneration agent supply system, a powder supply system, a finished material lifting and storage system, and a dust removal system. And control system 5 and so on.

[0021] The continuous double-drum recycled asphalt mixer consists of a frame 19, a movable burner 18 placed on the frame 19, an outer cylinder 20, an inner drum 21 with a driving transmission system 22, etc. The new aggregate supply system consists of a new aggregate transport device 25 with a new aggregate silo 28 placed on the top of the inner drum 21, a new aggregate conveyor 26 placed in the new aggregate silo 28, and a new aggregate continuous weighing hopper 27 and so on. The old asphalt mixture supply system consists of an old asphalt mixture transportation device 17 with an old asphalt mixture silo 13 placed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com