Method of preparing macromolecular breathable film

A polymer gas permeable membrane, automatic separation technology, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of inability to achieve effective permeation of six gases, low permeability, long equilibrium time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

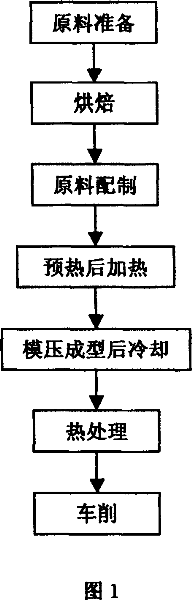

[0016] Example 1: The process flow of the preparation method of the polymer gas permeable membrane for the automatic separation of oil and gas, the purchased polytetrafluoroethylene and polyhexafluoropropylene raw materials are placed in containers respectively, put into a baking furnace, and after baking to 200 ° C, Insulate for 6 hours; prepare the baked raw materials according to 80% polytetrafluoroethylene and 20% polyhexafluoropropylene; stir the prepared raw materials evenly and place them in a container, put them in a baking furnace, and preheat them to 300°C , heat preservation for 5 hours, and then continue to heat to 380 ° C, heat preservation for 6 hours; put the heated raw materials in the mold, press molding by a press, the molding pressure is 100kg / cm 2 , the pressing time is 1 hour, and the thickness of the compressed air-permeable film is 0.05mm; put the pressed-formed air-permeable film into a baking furnace, heat it to 300°C, keep it warm for 20 hours, and the...

Embodiment 2

[0017] Example 2: The process flow of the preparation method of the polymer gas permeable membrane for the automatic separation of oil and gas, the purchased polytetrafluoroethylene and polyhexafluoropropylene raw materials are placed in containers respectively, put into a baking furnace, and after baking to 175 ° C, Insulate for 5 hours; prepare the baked raw materials according to 82.5% polytetrafluoroethylene and 17.5% polyhexafluoropropylene; stir the prepared raw materials evenly and place them in a container, put them in a baking furnace, and preheat them to 250°C , heat preservation for 4 hours, and then continue to heat to 340 ° C, heat preservation for 5 hours; put the heated raw materials in the mold, press molding by a press, the molding pressure is 75kg / cm 2 , the pressing time is 0.75 hours, and the thickness of the compressed air-permeable film is 0.075mm; put the pressed-formed air-permeable film into a baking furnace, heat it to 250°C, keep it warm for 15 hours,...

Embodiment 3

[0018] Example 3: The process flow of the preparation method of the polymer gas permeable membrane for the automatic separation of oil and gas, the purchased polytetrafluoroethylene and polyhexafluoropropylene raw materials are placed in containers respectively, put into a baking furnace, and after baking to 150 ° C, Keep warm for 4 hours; prepare the baked raw materials according to 85% polytetrafluoroethylene and 15% polyhexafluoropropylene; stir the prepared raw materials evenly and place them in a container, put them in a baking furnace, and preheat them to 200°C , keep warm for 3 hours, then continue to heat to 300°C, keep warm for 4 hours; put the heated raw materials in the mold, and press them into shape by a press, the molding pressure is 50kg / cm 2 , the pressing time is 0.5 hours, and the thickness of the pressed air-permeable film is 0.1mm; put the pressed-formed air-permeable film into a baking furnace, heat it to 200°C, keep it warm for 10 hours, and then take it o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com