Method for automatic generating device mark in printed circuit board design

A technology for automatically generating and printing circuit boards, which is applied in the fields of printed circuits, printed circuit manufacturing, and electrical components. The font is consistent and the effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

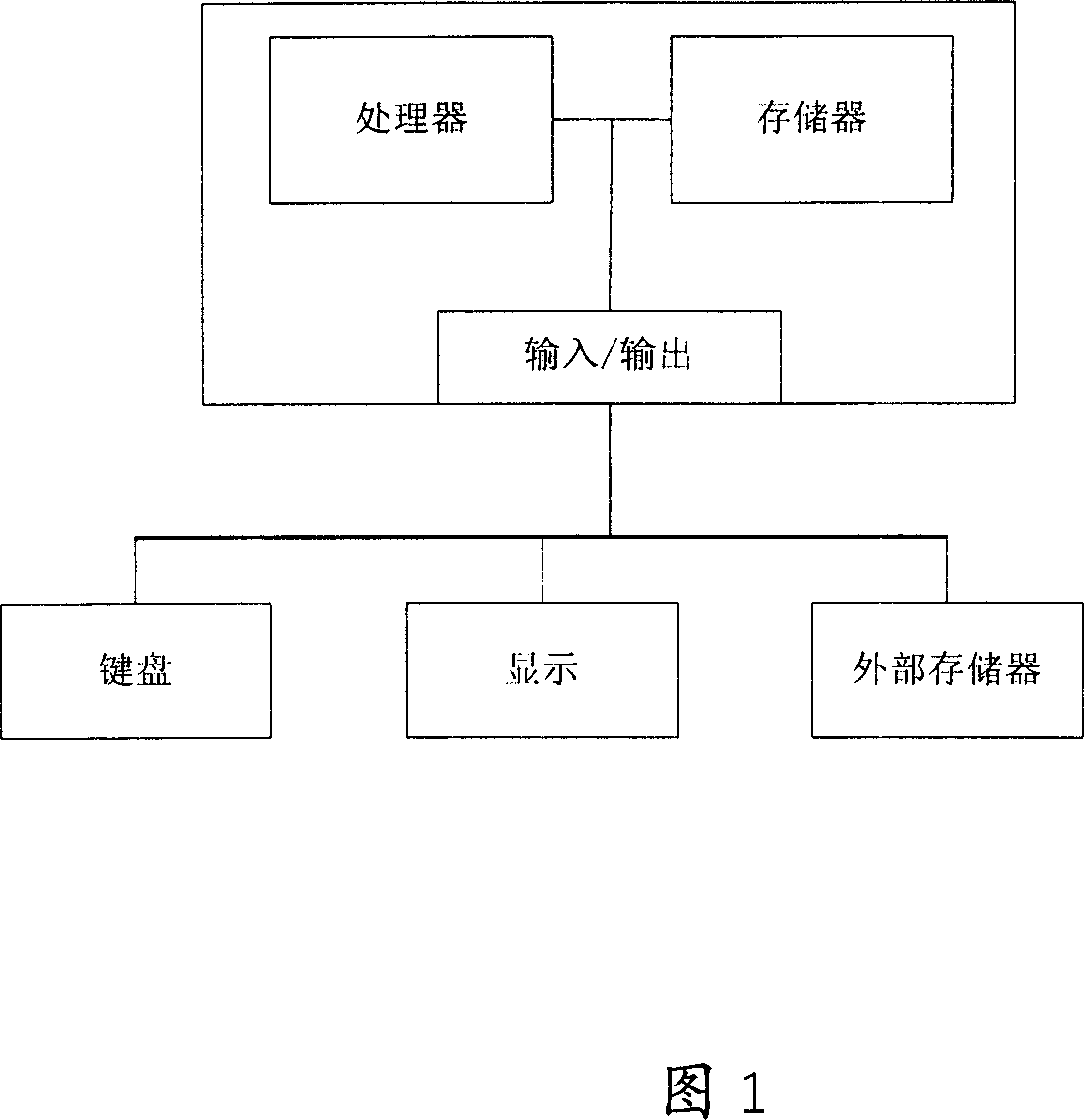

[0026] Figure 1 shows a computer used to implement the invention. The computer has a processor, which is connected to the memory through the bus, and is also connected to the input and output interfaces through the bus. The memory stores the circuit printed board design program. The input and output interface is connected to the keyboard, external memory and display, and the circuit printed board diagram is displayed through the display, or output through an output device such as a printer connected to the computer.

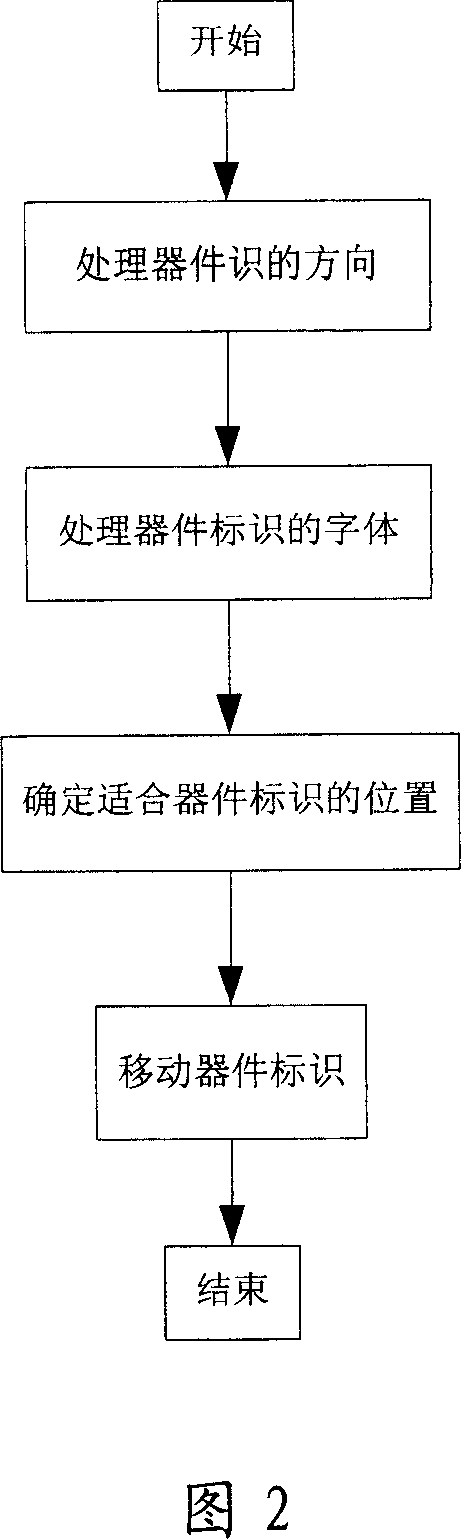

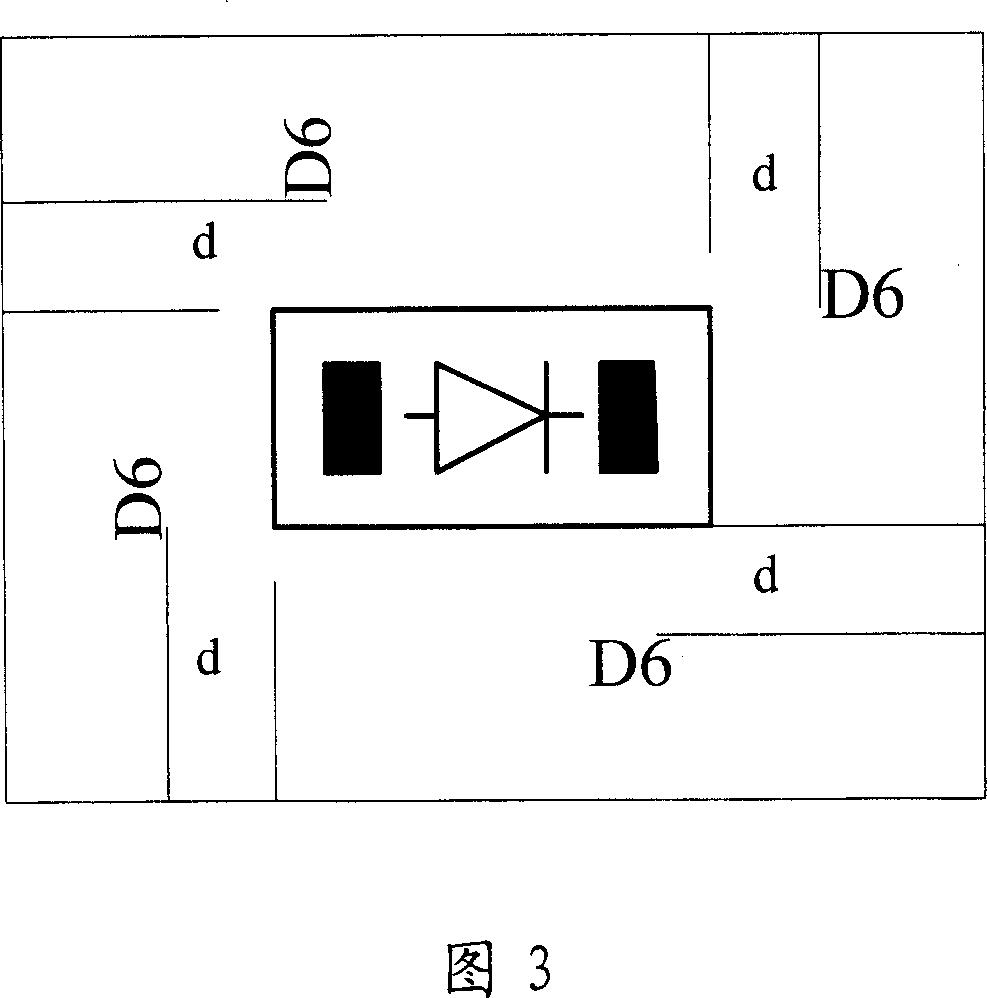

[0027] Since the device identification in the circuit printed board diagram generated by the computer device needs to meet the requirements from the process, production, debugging, specification, etc., after abstract processing, these requirements are transformed into the printed circuit board (referred to as PCB) design. Finally, it is required that the placement position of the device logo can be in the customary position that is usually manually adjusted. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com