Polymerization reactor for producing suspension type polyvinyl-chloride

A polymerization reactor and polyvinyl chloride technology, which is applied in the field of stirring devices and baffles, achieves the effects of uniform particle distribution, energy saving, and rapid and effective dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

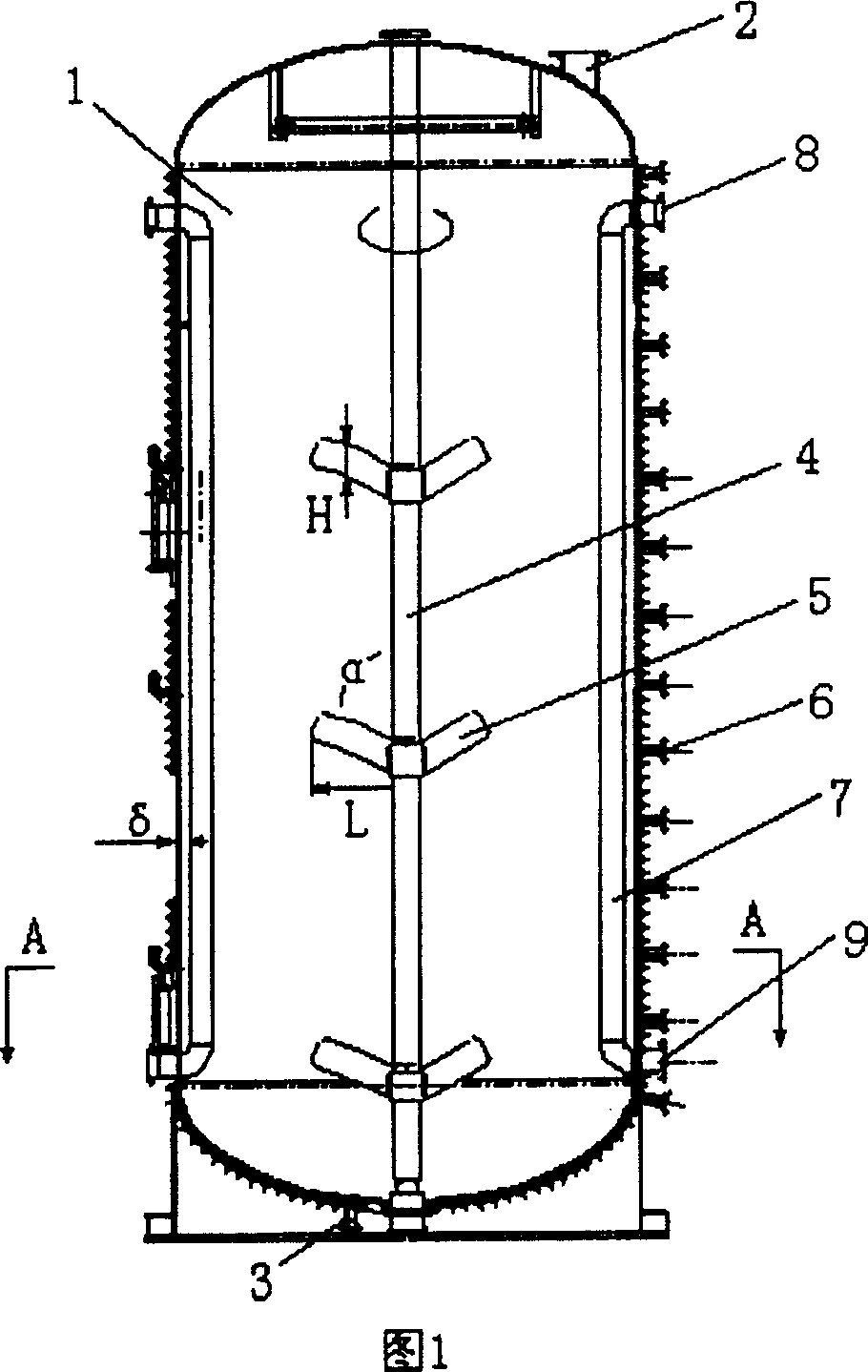

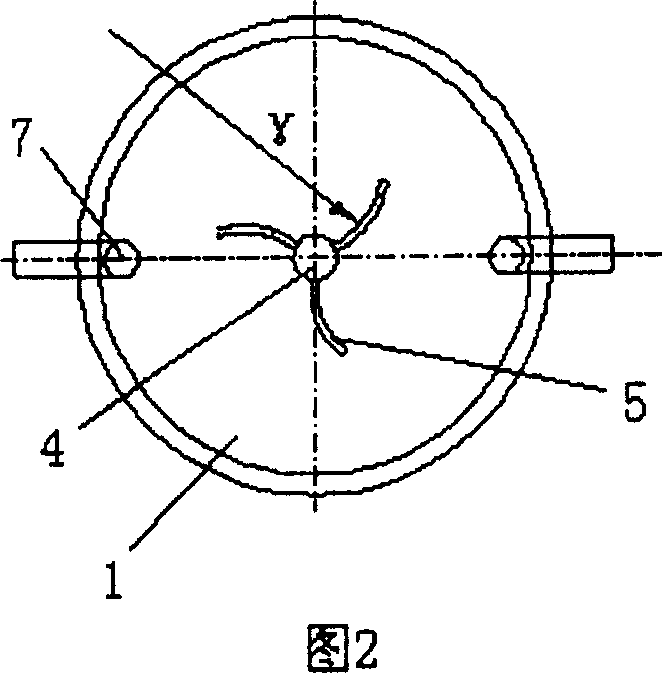

[0018] See Fig. 1 and Fig. 2, polymerization reactor of the present invention comprises:

[0019] A cylindrical vertical pressure vessel 1 with a material inlet 2 at the top and a material outlet 3 at the bottom. The volume of the cylindrical vertical pressure vessel 1 is 120-140 m3, and the ratio of height to inner diameter is: height : Inner diameter=10.4~0.6;

[0020] A stirring device axially installed in the pressure vessel 1, the stirring device used in the present invention includes a stirring shaft 4 axially installed in the reactor 1 and a three-layer oblique paddle stirring device arranged on the stirring shaft 4 Paddle, each layer of stirring paddles is provided with three arc-shaped paddles 5 having an angle α with the stirring shaft 4; 400-600mm, the length L of the paddle 5 is 0.4-0.6 of the inner diameter of the reactor 1;

[0021] An external cooling coil 6 arranged outside the pressure vessel;

[0022] Two internal cooling pipes 7 vertically arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com