Progresive stepless variable speed gear

A stepless speed change device, progressive technology, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problem of large wear of variable diameter steel wheels and steel belts, increased difficulty of control technology, low penetration rate, etc. problem, to achieve the effect of improving efficiency, wide application range and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

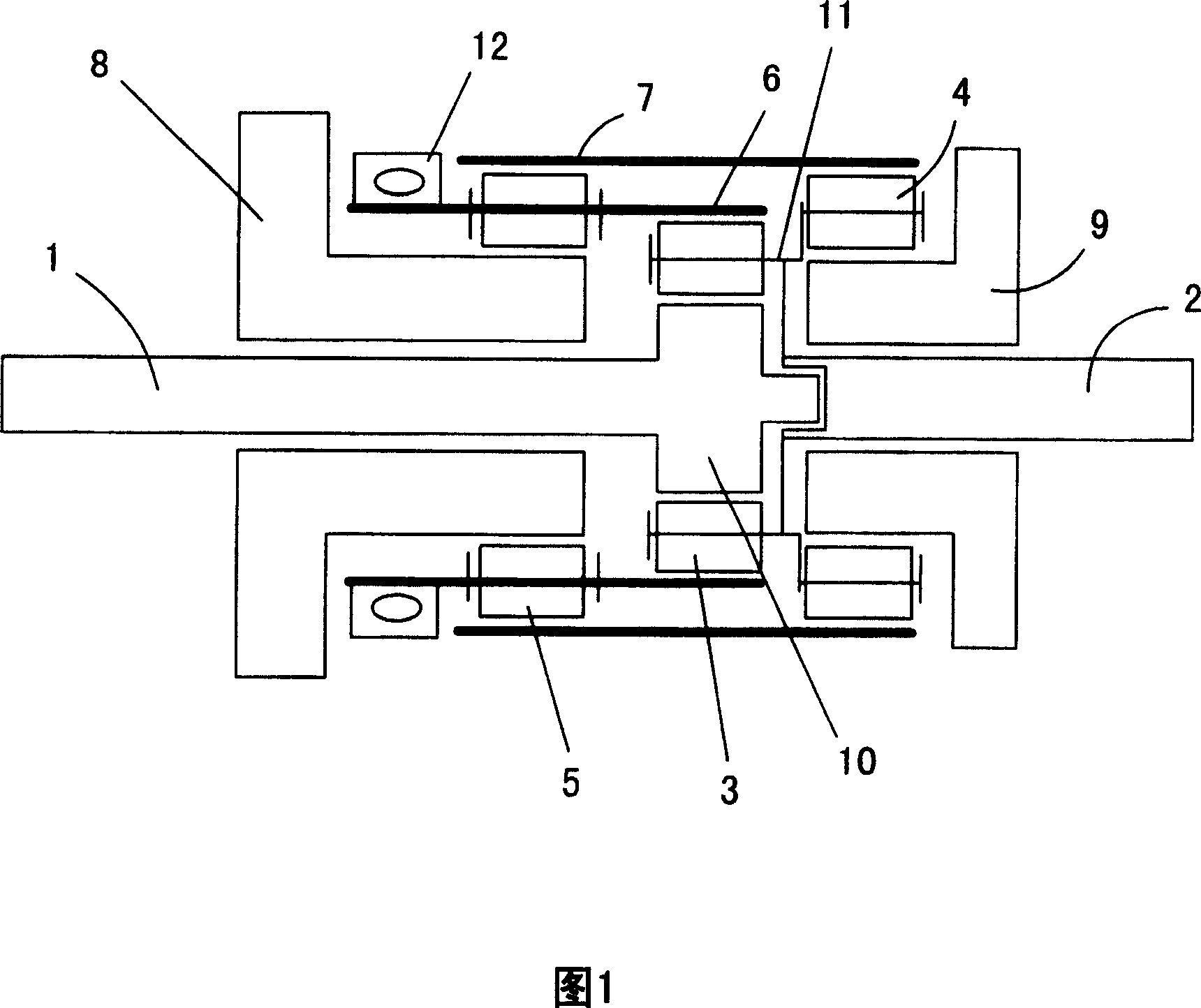

[0014] Figure 1 shows the first embodiment of the progressive continuously variable transmission device of the present invention, which includes an input shaft 1, an output shaft 2, a first planetary gear set 3, a second planetary gear set 4, and a third planetary gear set 5 , the first ring gear 6, the second ring gear 7, the first speed-regulating sun gear 8, the second speed-regulating sun gear 9 and the input sun gear 10, etc., the two speed-regulating sun gears 8 and 9 can be respectively controlled by the speed limiting device Controlling, the first speed-adjusting sun gear 8 can rotate around the input shaft 1 and be separated from the rotation of the input shaft 1 , and the second speed-regulating sun gear 9 can rotate around the output shaft 2 and be separated from the rotation of the output shaft 2 . The input shaft 1 and the input sun gear 10 rotate synchronously, and they can be of integral structure, also can be of fixed connection, and can also be of separate stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com