Installation structure of cam chain guide apparatus

An installation structure, cam chain technology, applied in the direction of chain/belt transmission, valve device, transmission device, etc., can solve the problems of increasing the friction between the cam chain tensioner and the cam chain, affecting the output power of the engine, and eliminating the need for installation Effects of loosening, impact reduction, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

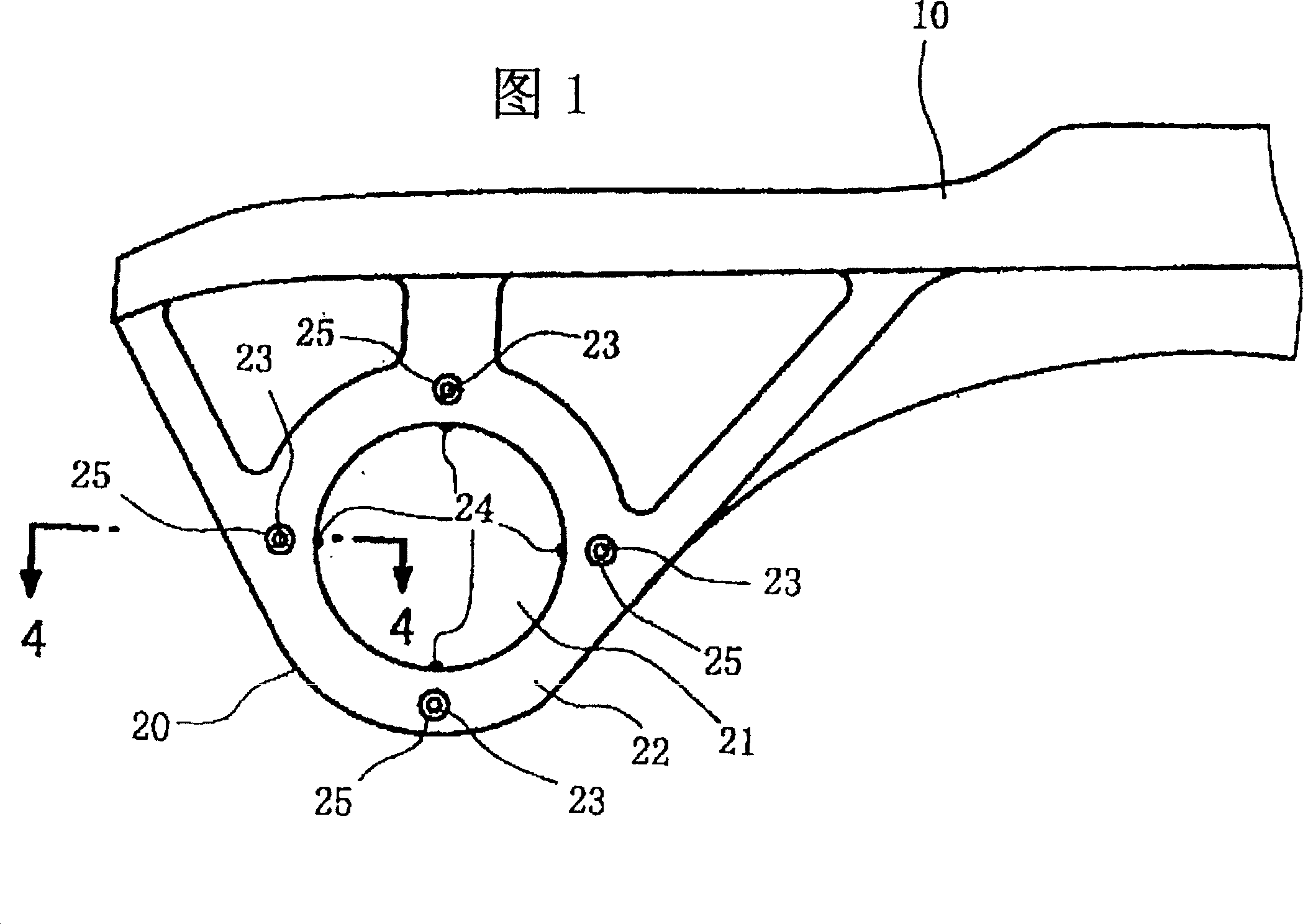

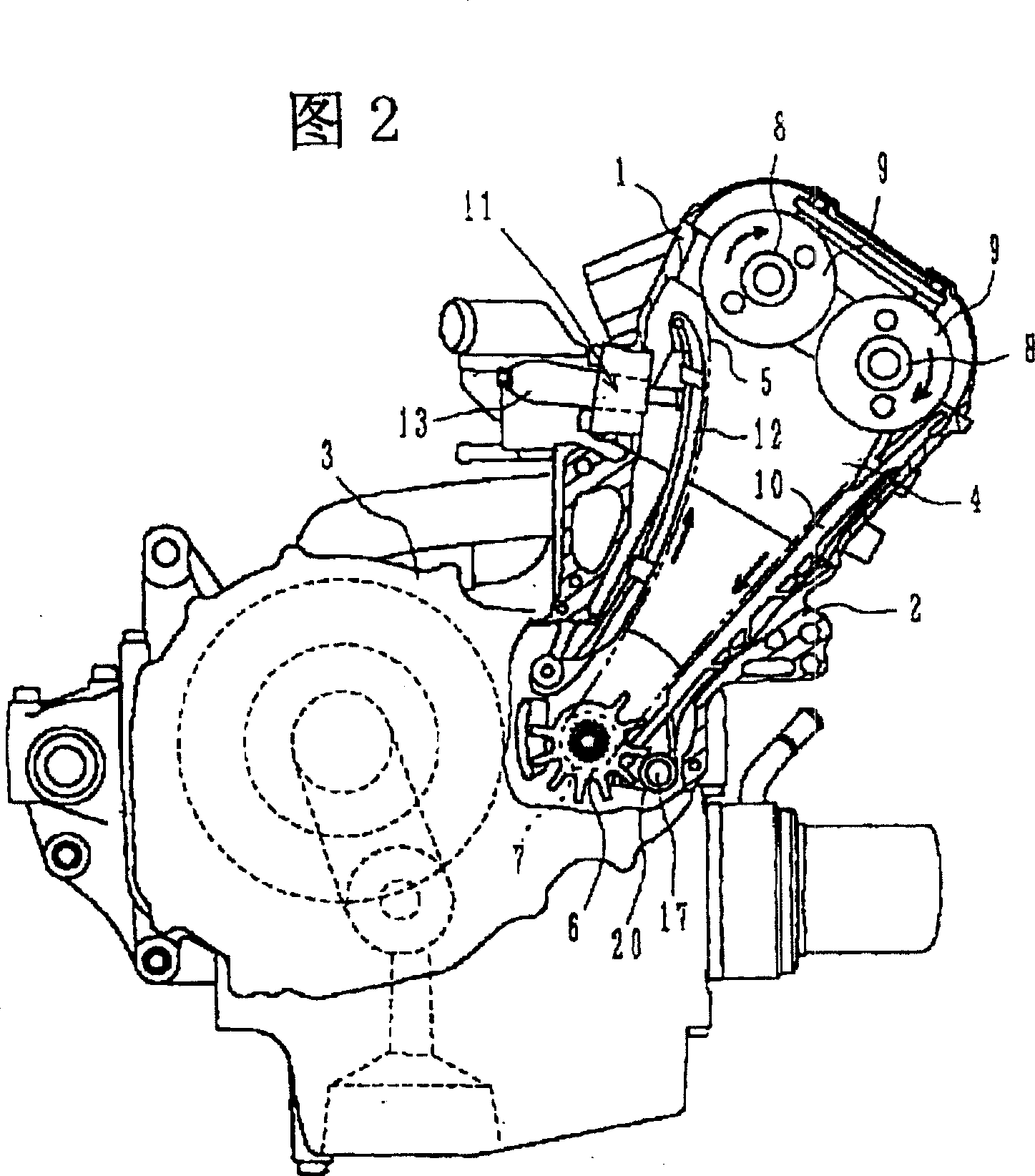

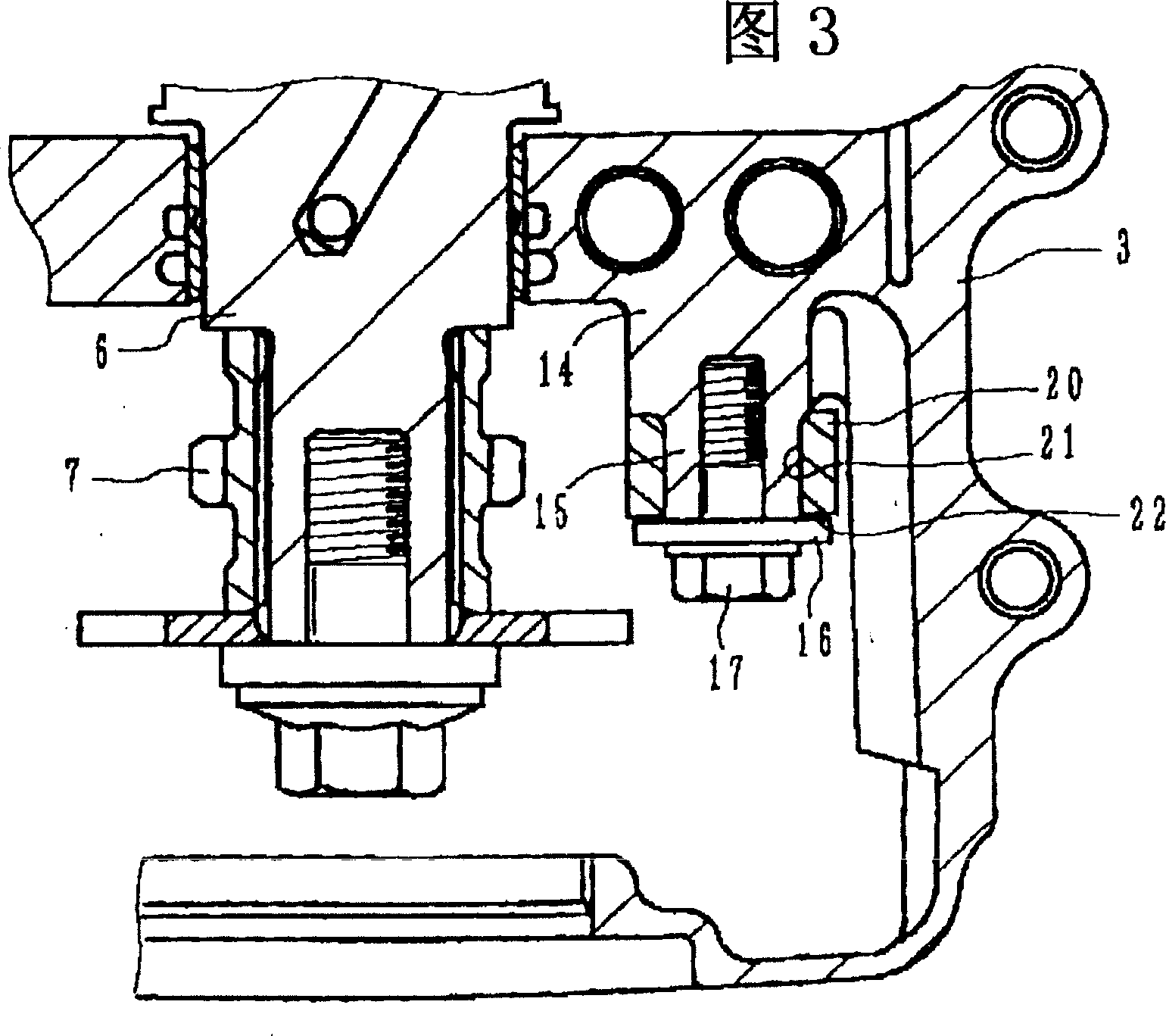

[0021] Below, illustrate an embodiment that is applicable to motor two-wheel vehicle engine by accompanying drawing. Fig. 1 is a side view of the installation end of the indicated cam chain guide viewed from the installation direction; Fig. 2 is a diagram of the engine cut open to show its valve mechanism; Fig. 3 is a diagram of the installation structure of the cam chain guide; Fig. 4 is a cross-sectional view along line 4-4 of Fig. 1; Fig. 5 is a graph showing the noise reduction effect.

[0022] First, the overall schematic structure of the engine will be described with reference to FIG. 2 . This engine is a DOHC 4-cycle engine, 1 is a cylinder head, 2 is a cylinder block, 3 is a crankcase, and a cam chain 5 is accommodated in a cam chain chamber 4 provided on one side of these components.

[0023] The cam chain 5 is wound between the driving sprocket 7 formed on one end of the crankshaft 6 and each cam sprocket 9 on the two camshafts 8, and constitutes a drive transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com