Oil-fog purifier set

A unit and oil mist technology, applied in the field of separation, can solve the problems of only 30% purification efficiency of tiny oil mist particles, manual cleaning of steel plates, inconvenient disassembly and assembly, poor purification effect, etc., and achieves easy assembly, convenient replacement, and purification. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

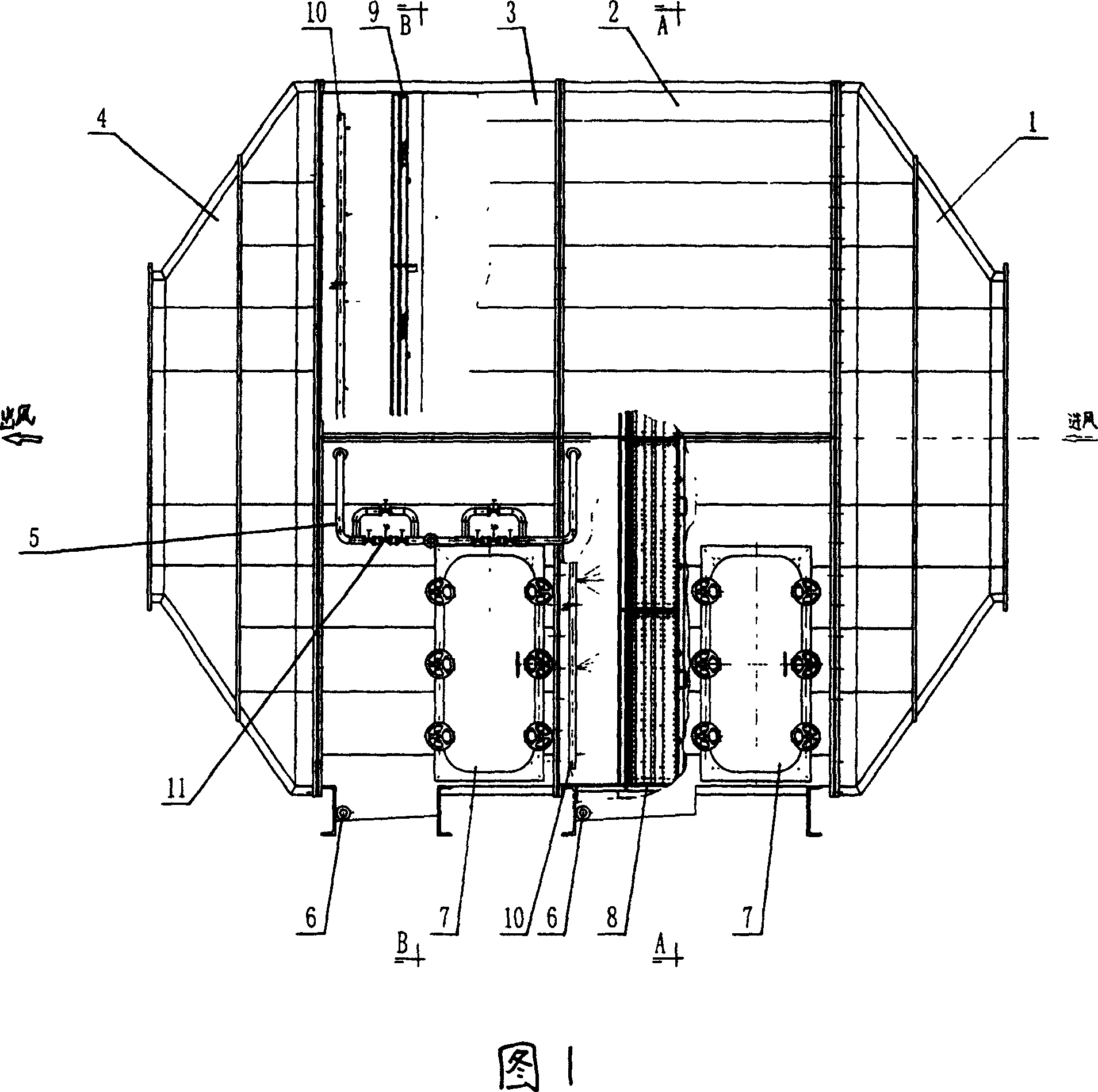

[0027] The present invention will be further described below in conjunction with accompanying drawing:

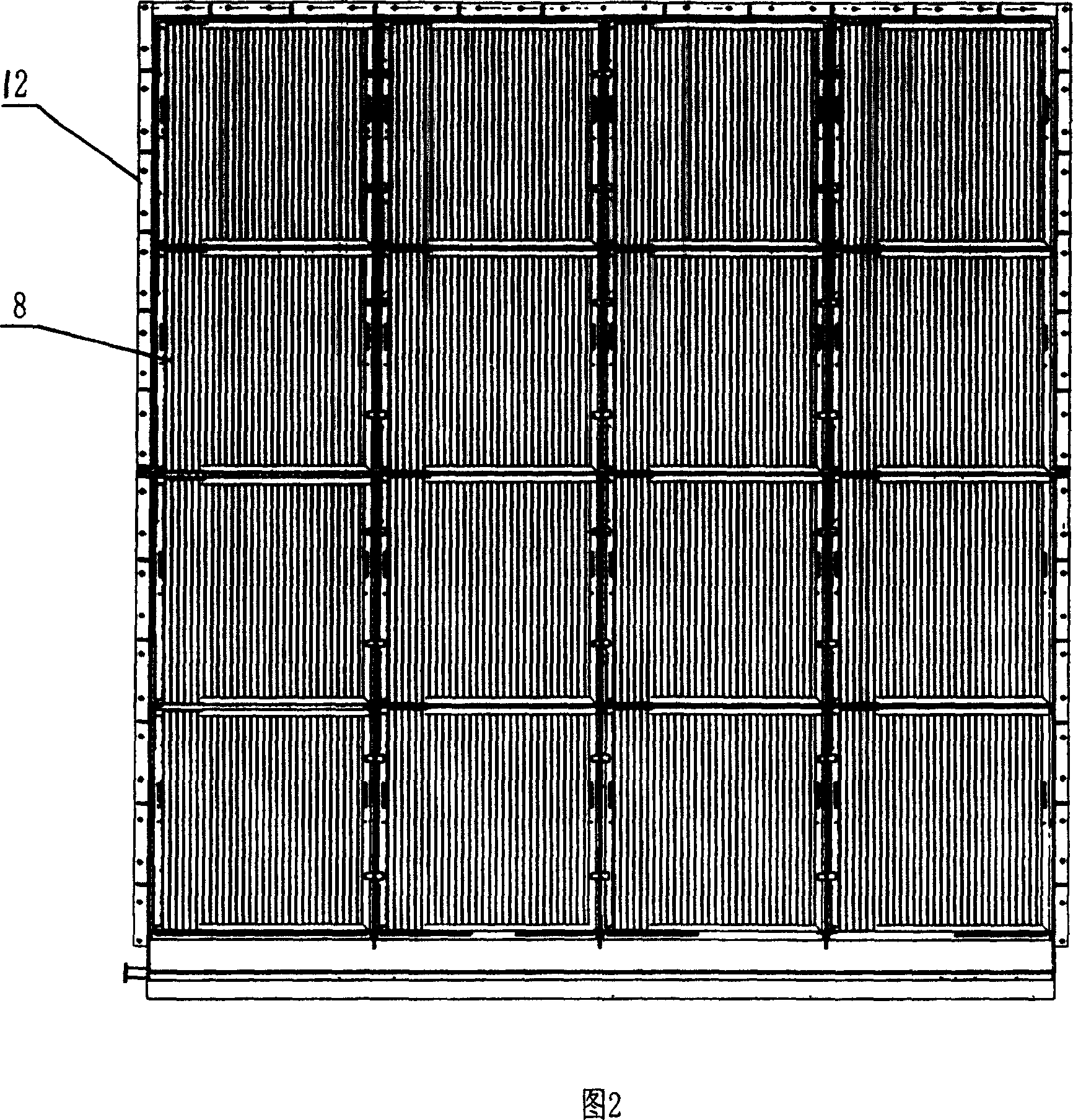

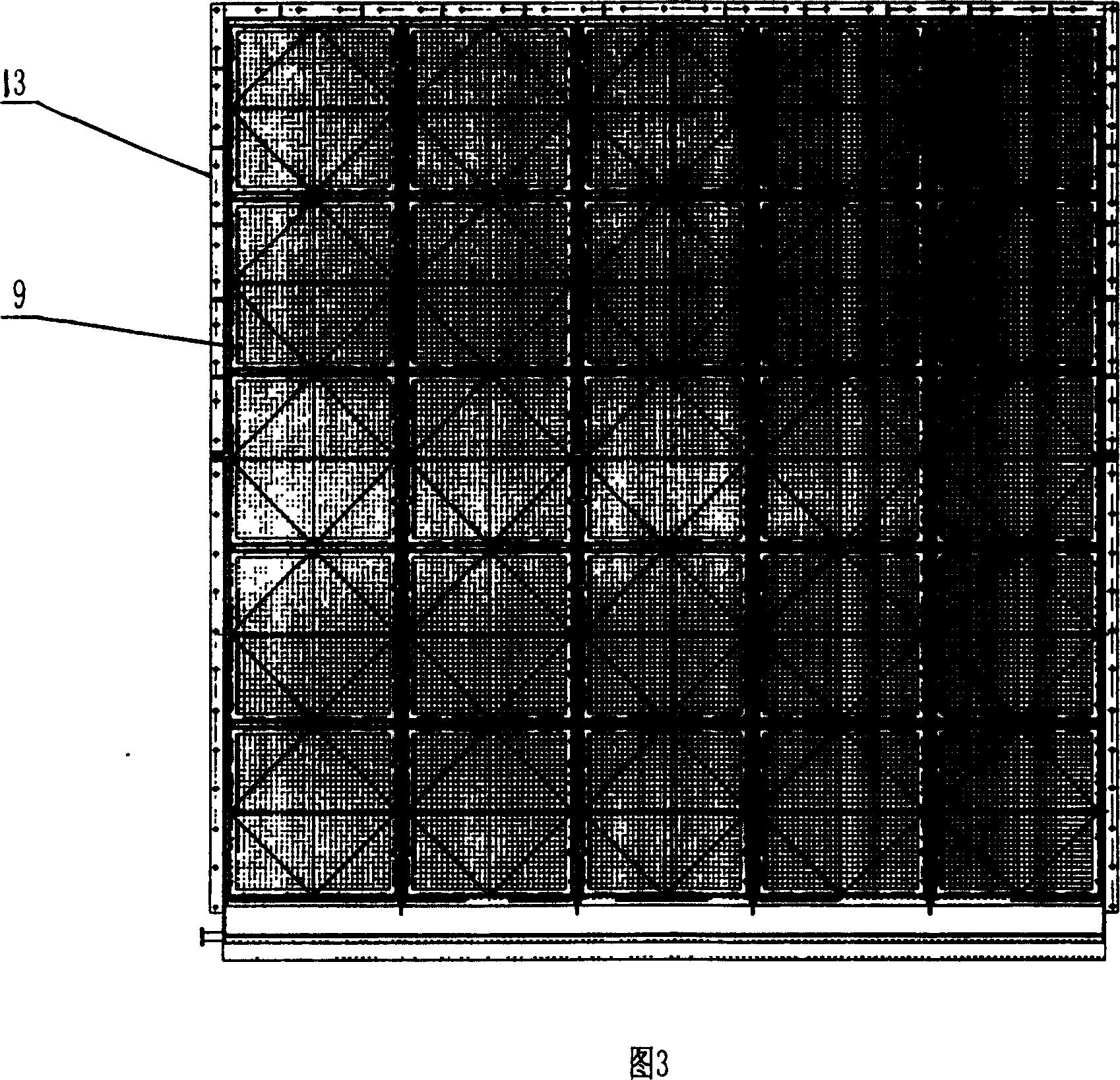

[0028] The oil mist purification unit of the present invention is composed of an air inlet section 1, a purification section, and an air outlet section 4, wherein the purification section is composed of a liquid blocking section 2 and a collecting section 3, and the liquid blocking section 2 is composed of a liquid blocking device modules 8 are combined, and the trapping section 3 is formed by trap modules 9 . The liquid retainer module 8 is composed of a stainless steel plate formed by pressing and bending the liquid retainer 16 and the frame 14 to form a module, and the catcher module 9 is composed of a multi-layer stainless steel filter mesh combined with a catch net 17, a frame 15, and a bead 18 It is formed by pressing the connecting bolt 19; the steam cleaning exhaust pipe 10 is installed in the liquid blocking section 2 and the trapping section 3, and the steam clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com