Use of microwaves in the spinning industry

A fiber bundle and preparation machine technology, applied in fiber processing, fiber processing safety devices, measuring devices, etc., can solve problems such as affecting adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

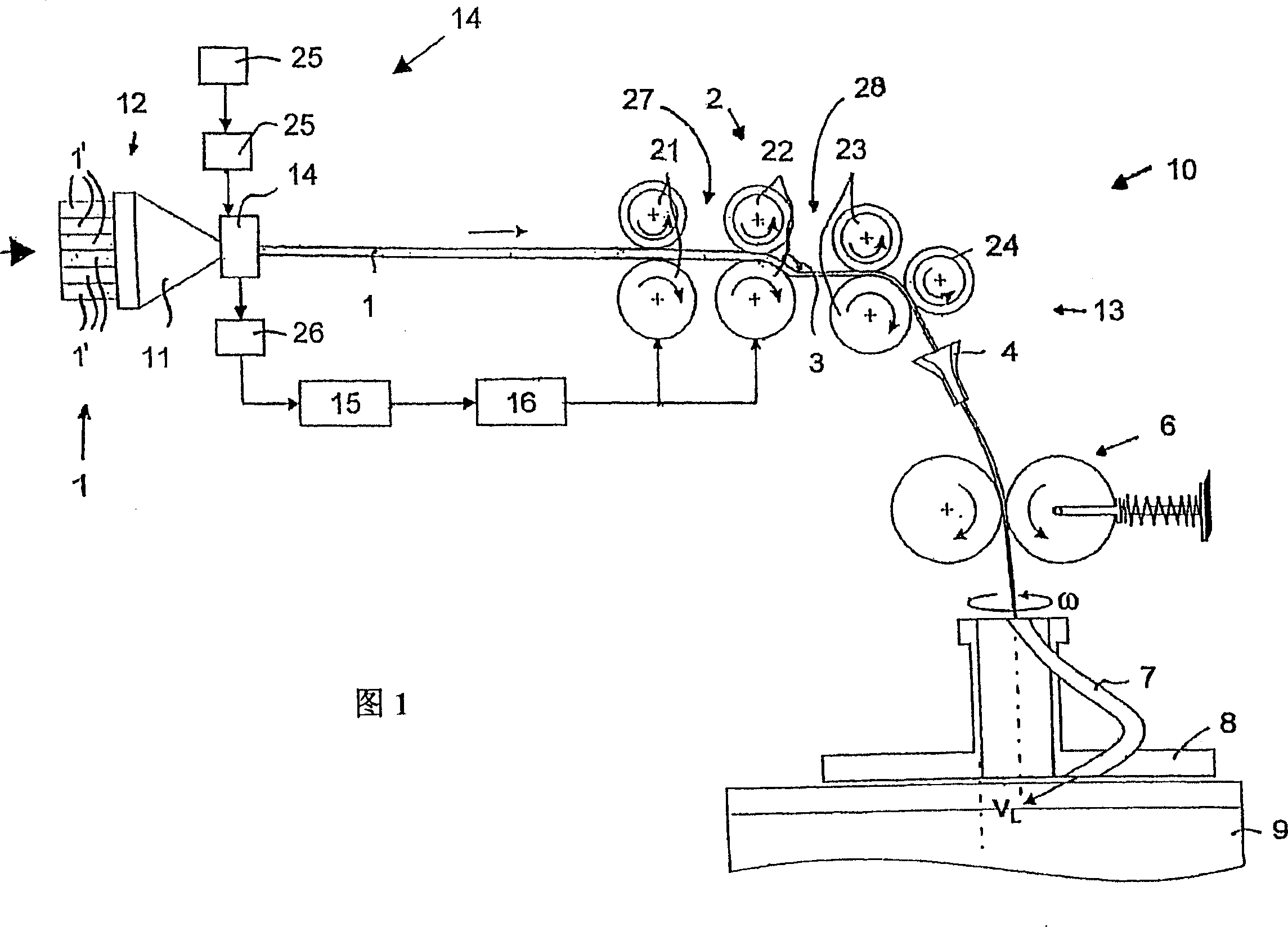

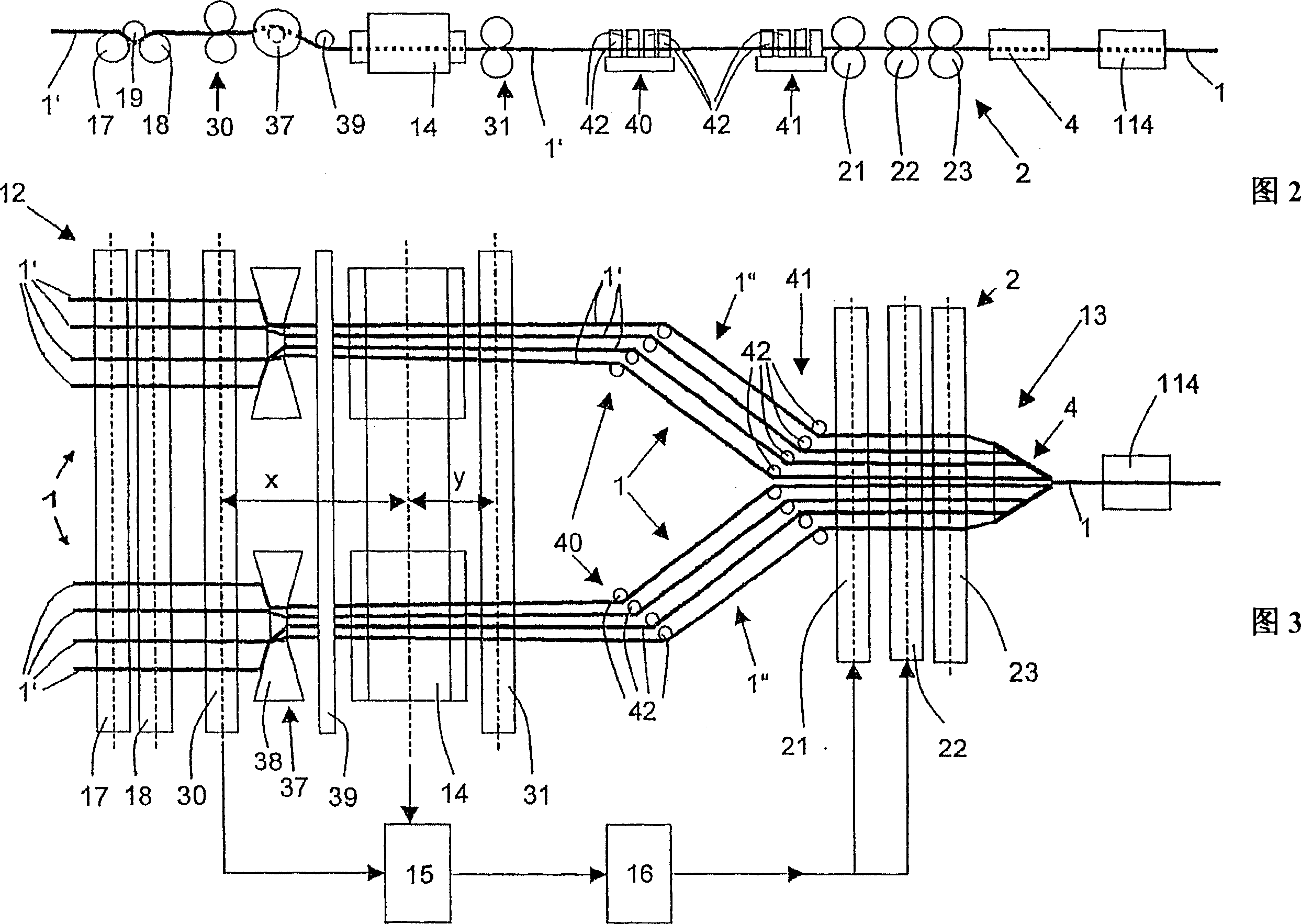

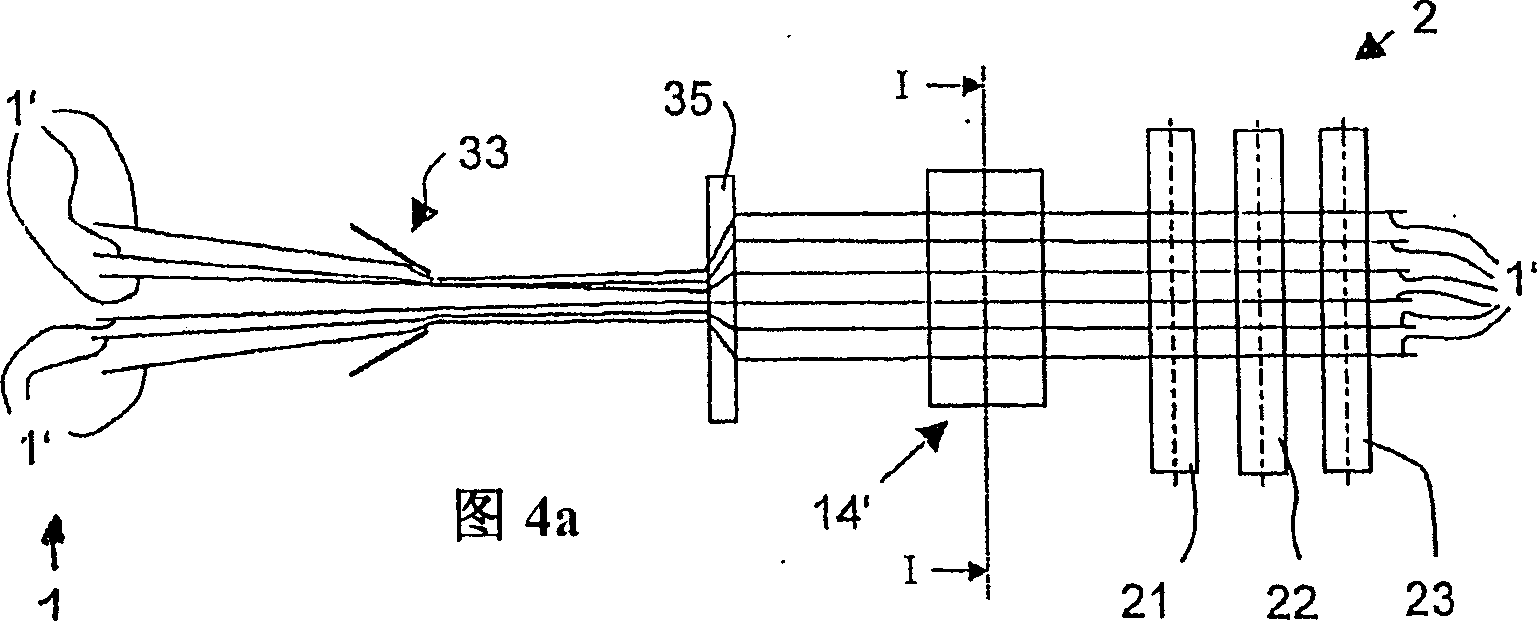

[0058] The basic mode of operation of the drafting machine 10 is explained below with reference to the accompanying drawing 1, which serves as an example of a spinning preparation machine. According to this example, a plurality of substantially untwisted slivers 1' are presented to the drafting machine 10 side by side. It is also possible to convey only one sliver 1 ′ to the drafting machine 10 . In both cases, within the scope of the present invention, the term "fiber bundle" is used for the presented fiber material, which is followed by the reference numeral 1 . Arranged at the inlet of the drafting machine 10 is a bell mouth 11 which condenses the sliver 1' or fiber bundle 1 . Alternatively, other condensation devices can also be used. It is also conceivable to dispense with the condensation altogether. After passing through a detection device or a sensor to be described below, the sliver 1 is guided into a drafting device 1 which forms the core part of the drafting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com