Protein crystallization apparatus, method of protein crystallization, protein crystallizing agent and process for preparing the same

A protein crystallization and crystallization agent technology, applied in the field of protein crystallization agent and its preparation, can solve the problems of crystallization agent movement, crystallization agent concentration and type inconsistency, mixed pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

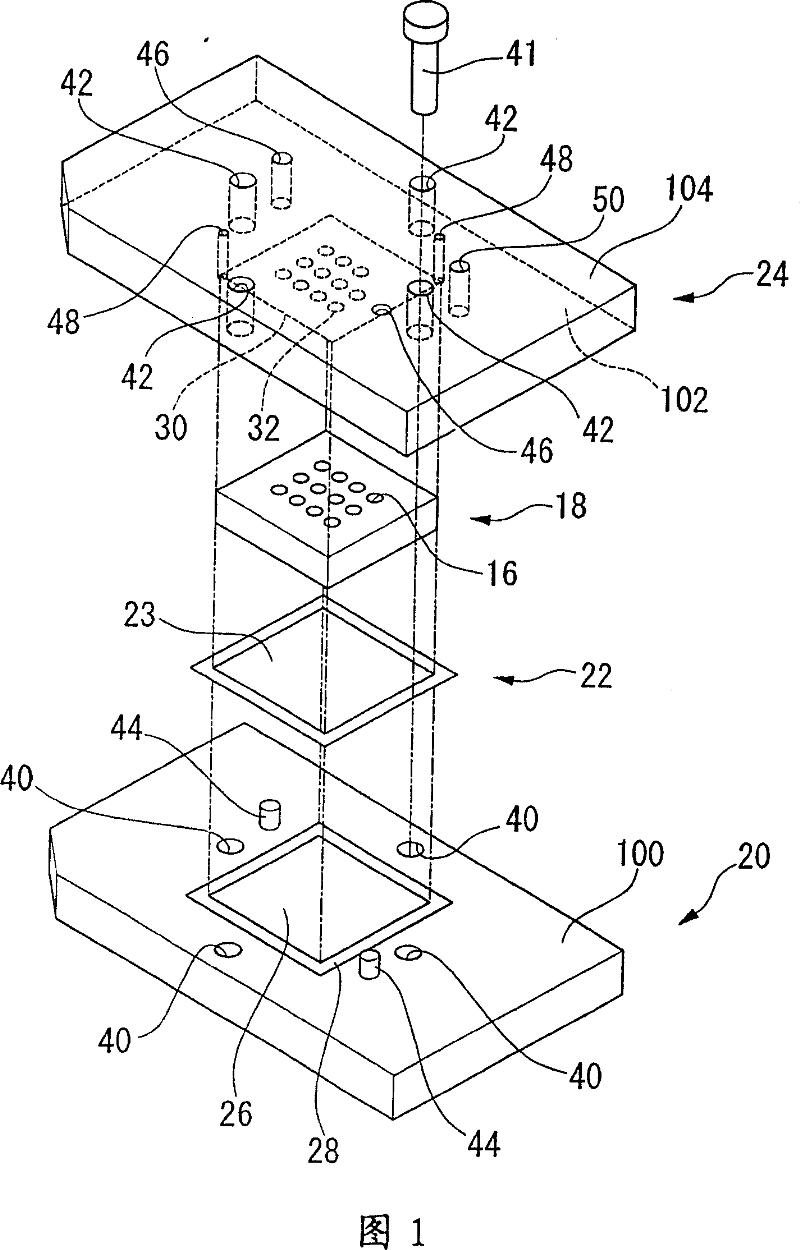

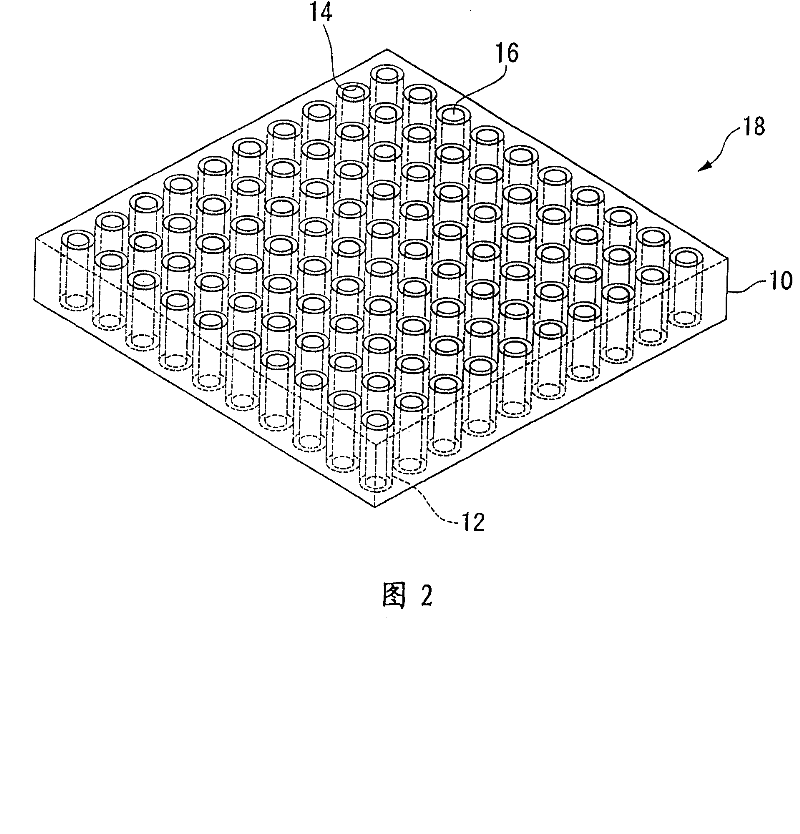

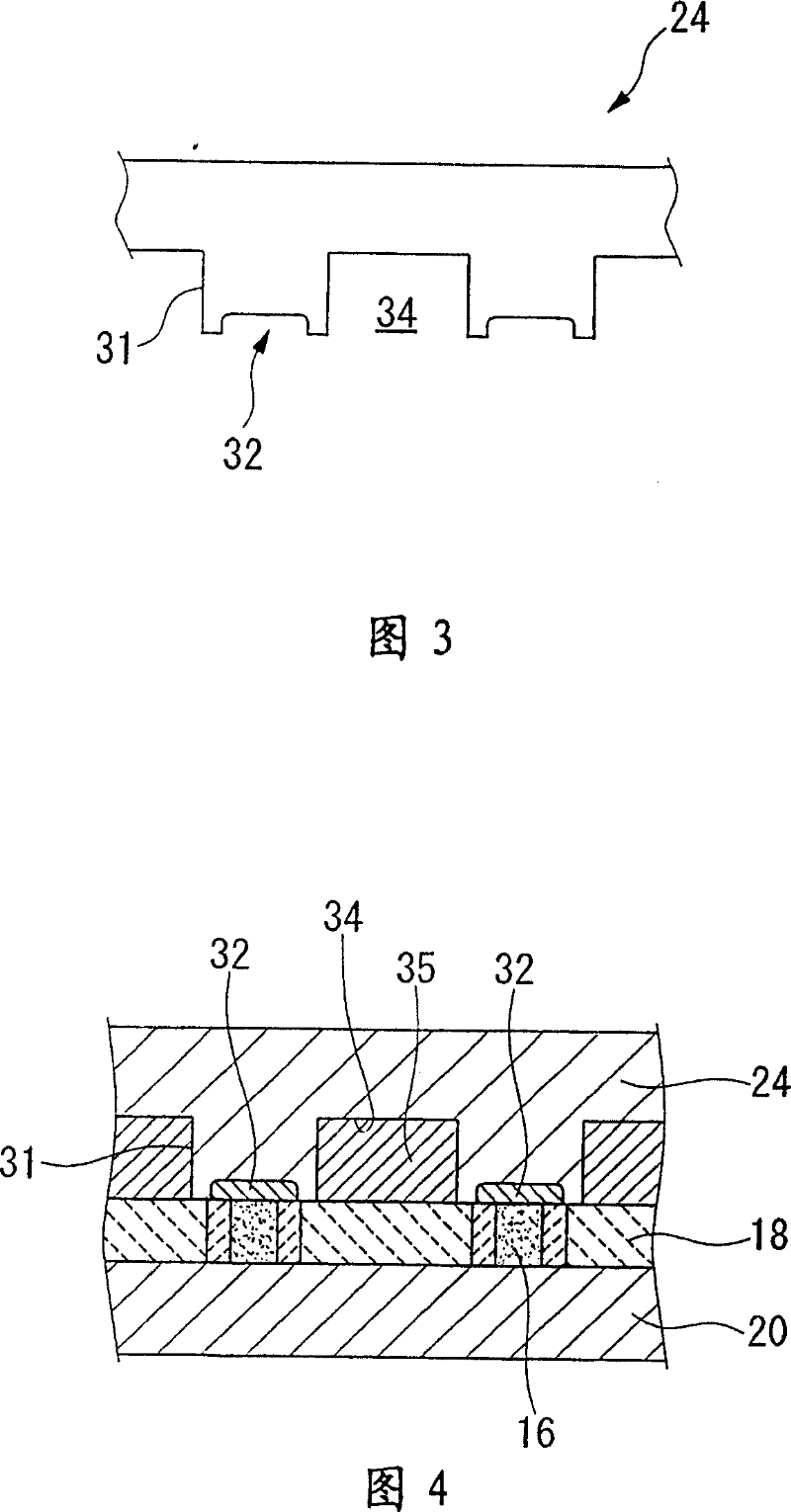

Method used

Image

Examples

Embodiment 1

[0185] Weighing 0.48g of sodium chloride as precipitating agent is put into 10ml volumetric flask, constant volume with 0.1M-citric acid buffer (pH4.0), prepares 1.2M-NaCl aqueous solution (this solution is designated as a liquid). In addition, 5 g of N, N'-methylenebisacrylamide (hereinafter abbreviated as MBAAm) and 5 g of deionized water were added to 90 g of a 50% aqueous solution of acrylamide (manufactured by Mitsubishi Rayon Co., Ltd.) to prepare a 50% monomer solution. (This solution is designated as liquid b). Furthermore, 2,2'-azobis[2-(2-imidazolin-2-yl)propane] dihydrochloride (manufactured by Wako Pure Chemical Industries, VA-044) as a water-soluble polymerization initiator was prepared in 10 % aqueous solution (this solution is defined as liquid c). Inject 840 μl of solution a and 160 μl of solution b into a 2 ml sample tube and mix to prepare an aqueous protein crystallization agent solution (1.0M-NaCl, pH 4.0, monomer concentration 8%), then add 10 μl of solu...

Embodiment 2

[0187] In addition to changing the concentration of liquid a in Example 1 to 2.4M, the others are prepared according to the same procedure as the crystallization agent aqueous solution (2.0M-NaCl, pH4.0, monomer concentration 8%), and then follow the same procedure Steps to obtain a transparent hydrogel. Also, the formation of lysozyme crystals was confirmed by the same method. The results are shown in Table-1.

Embodiment 3

[0188] Except changing the concentration of liquid a in Example 1 to 3.6M, other all prepare crystallization agent aqueous solution (3.0M-NaCl, pH4.0, monomer concentration 8%) according to the same procedure, then follow the same procedure Steps to obtain a transparent hydrogel. Also, the formation of lysozyme crystals was confirmed by the same method. The results are shown in Table-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com