Shaft hole part and shaft connection structure

A technology that combines structure and shaft hole, applied in the direction of bearing components, shafts and bearings, rigid shaft couplings, etc., can solve problems such as impossible, unobtainable, and cost-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

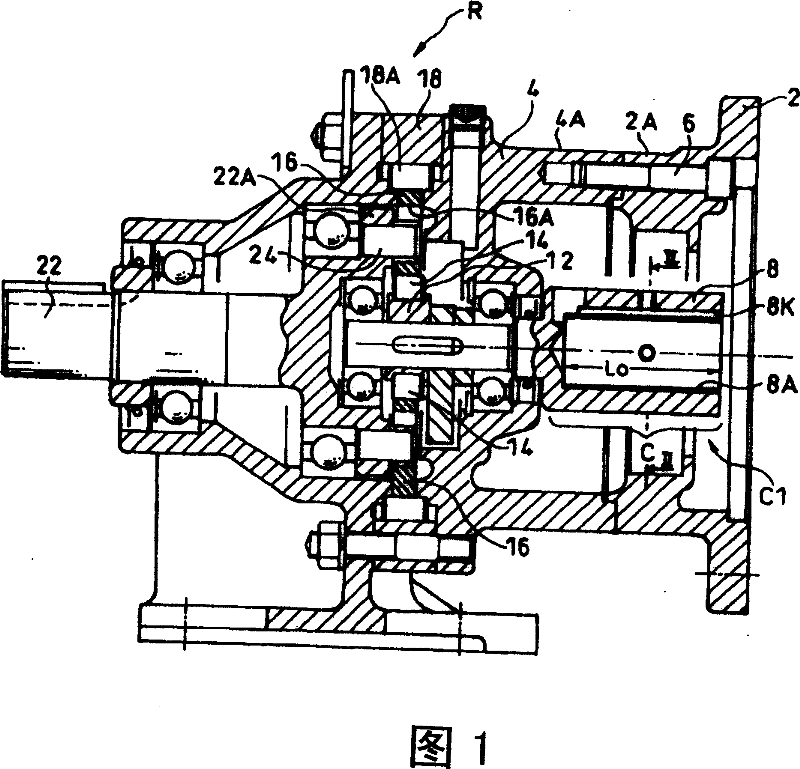

[0029] In this embodiment, the present invention is applied to a coupling portion that connects the motor shaft of the motor not shown in the drawings with the input shaft of the speed reducer.

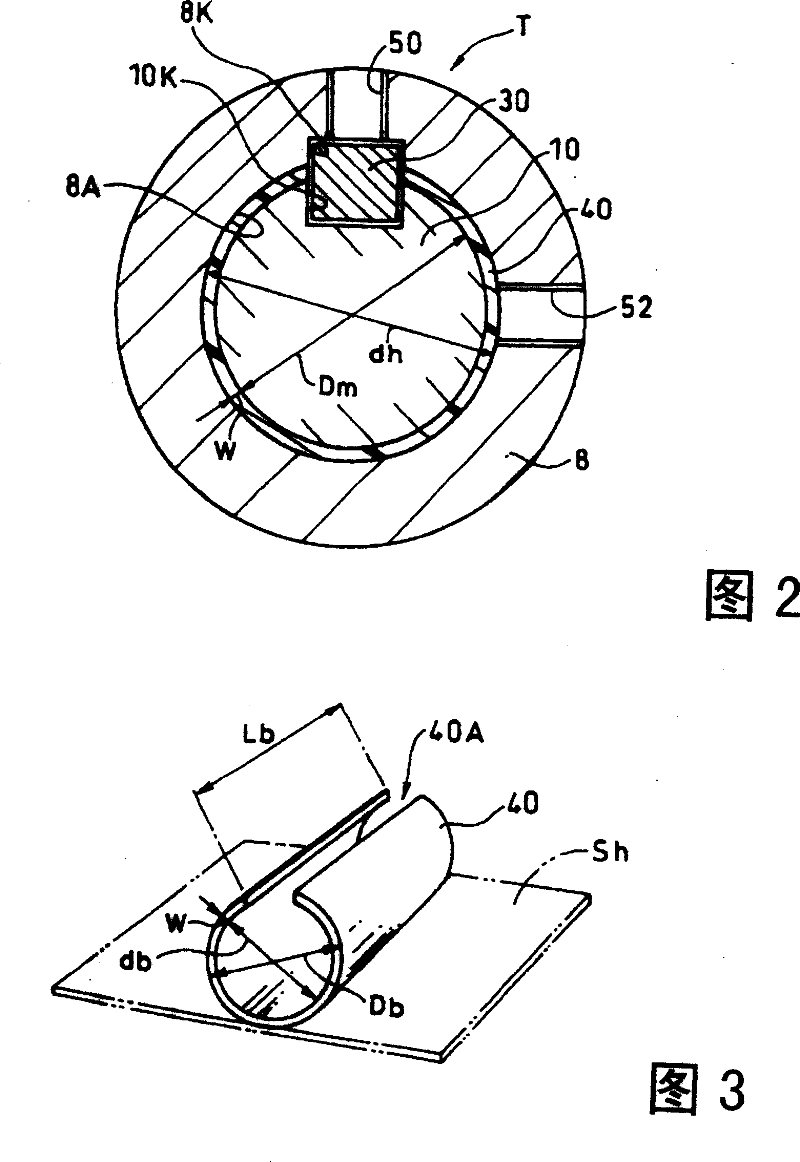

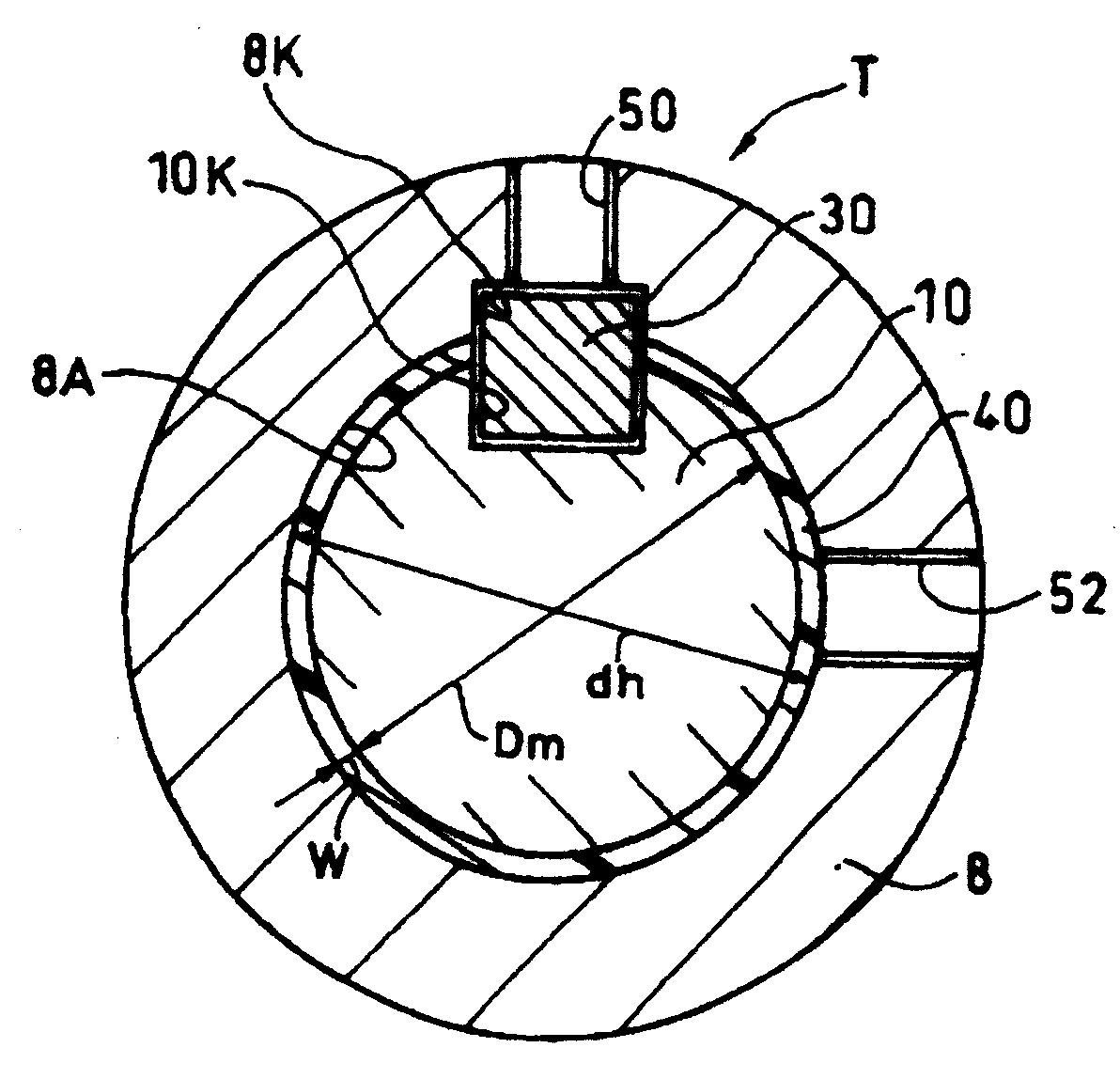

[0030] In FIG. 1 and FIG. 2 , symbol 2 is a connecting sleeve connected to a motor not shown in the figure, and 4 is a sleeve on the input side of the reducer R. The connecting sleeve 2 is connected to the sleeve 4 on the input side by bolts 6 , and the input shaft (shaft hole member) 8 of the speed reducer extends to the inside of the ring portions 2A, 4A of the sleeves 2 , 4 . A coupling portion C (described in detail later) between the input shaft 8 and the motor shaft 10 (refer to FIG. 2 , which is omitted in FIG. 1 ) is formed on the extension portion, that is, the base end portion of the input shaft 8 of the reducer R.

[0031] The speed reducer R itself is kno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com