Centrifugal separator

A centrifugal separator and separator technology, applied in centrifuges, centrifuges with rotating drums, etc., to achieve the effects of large gas flow rate, high separation efficiency, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

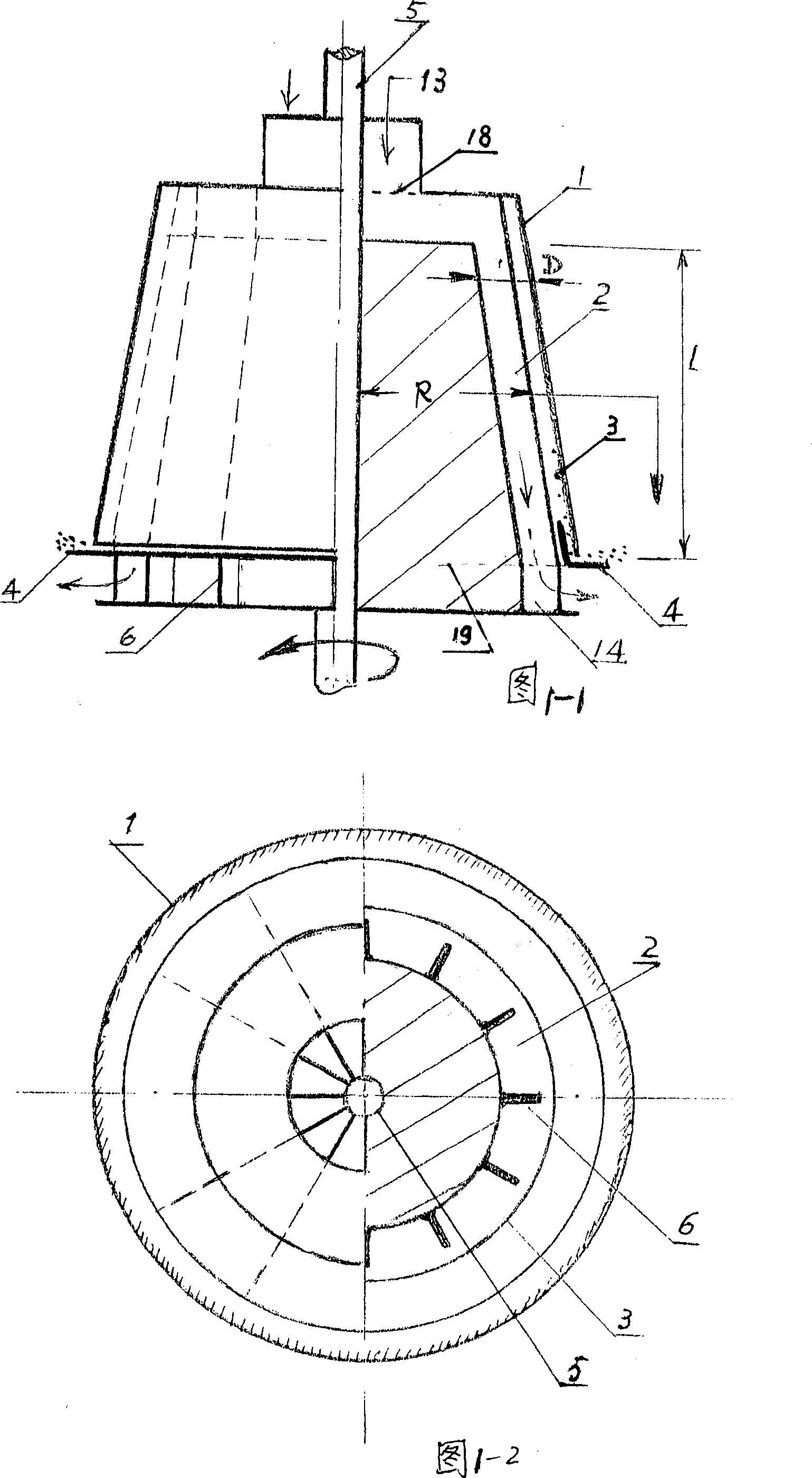

[0024] Fig. 1-1 and Fig. 1-2 show that the present invention is used for centrifugal separation of gas dust removal

[0025] The principle schematic diagram of the longitudinal and transverse cross-sectional views of the settling tubes of the device interpenetrating with each other. In the figure, the outer casing 1 contains the settling tube 2 inside and is evenly separated by the partition plate 6 in the circumferential direction. Two inner and outer circular platforms symmetrical to the rotating shaft 5 The space sandwiched by the sides is obtained, wherein the outer round table surface is smooth, which is used as the settlement surface 3, and there is no connection between the partition plate 6 and the settlement surface 3 but a gap, which makes each settlement The connection between the pipes increases the area of the settling surface 3 and helps to prevent the accumulation of accumulated dust.

[0026] The settling surface 3 extends continuously from the inlet end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com