Fuel battery with constant pressure air as oxidant and coolant

A fuel cell and oxidant technology, which is applied to fuel cells, battery electrodes, circuits, etc., can solve the problems of poor low-temperature startup performance of battery stacks and poor low-temperature operability of battery stacks, and achieve improved low-temperature startup performance and energy consumption. The effect of low, lower volumetric specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

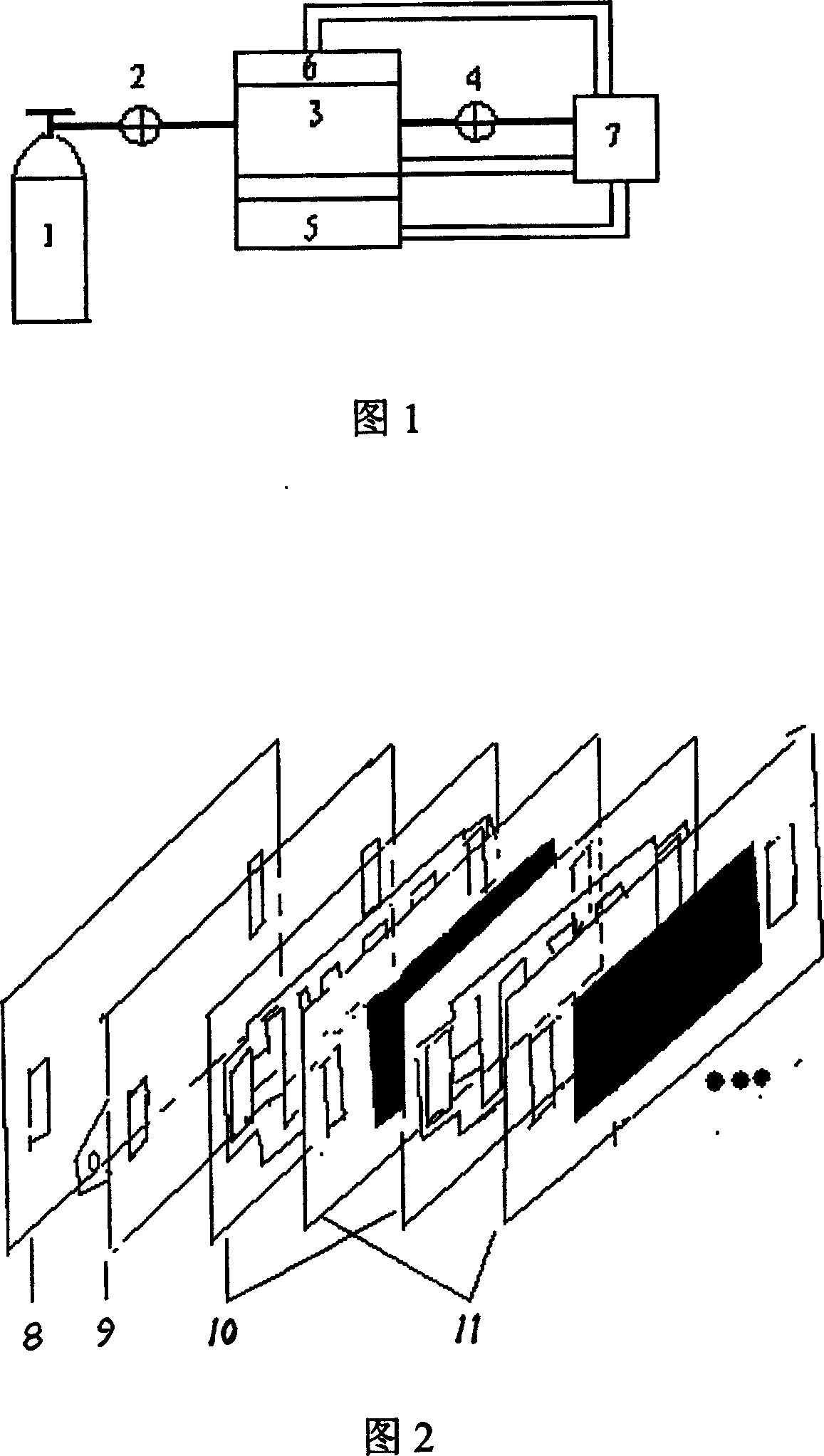

[0023] Accompanying drawing 1 has given the structural schematic diagram of whole battery system; Hydrogen storage tank 1 is a metal hydrogen storage tank, and a certain amount of hydrogen is stored in the tank, enters fuel cell stack 3 after passing through pressure reducing valve 2, and the outlet of fuel cell stack 3 is set There is a hydrogen flow control valve 4, 5 is a fan, which can directly use the electric energy generated by the fuel cell to provide air to the fuel cell, 6 is the air flow ratio adjustment device, and 7 is the battery system control circuit, which uses the power generated by the fuel cell Electric energy, provide electric energy for 4, 5, 6 and detect and control their running status.

[0024] The whole battery system works like this: the hydrogen in the hydrogen storage tank 1 enters the hydrogen gas side of the electrode plate of the fuel cell stack 3 after passing through the pressure reducing valve 2, and forms a superimposed voltage with the air o...

Embodiment 2

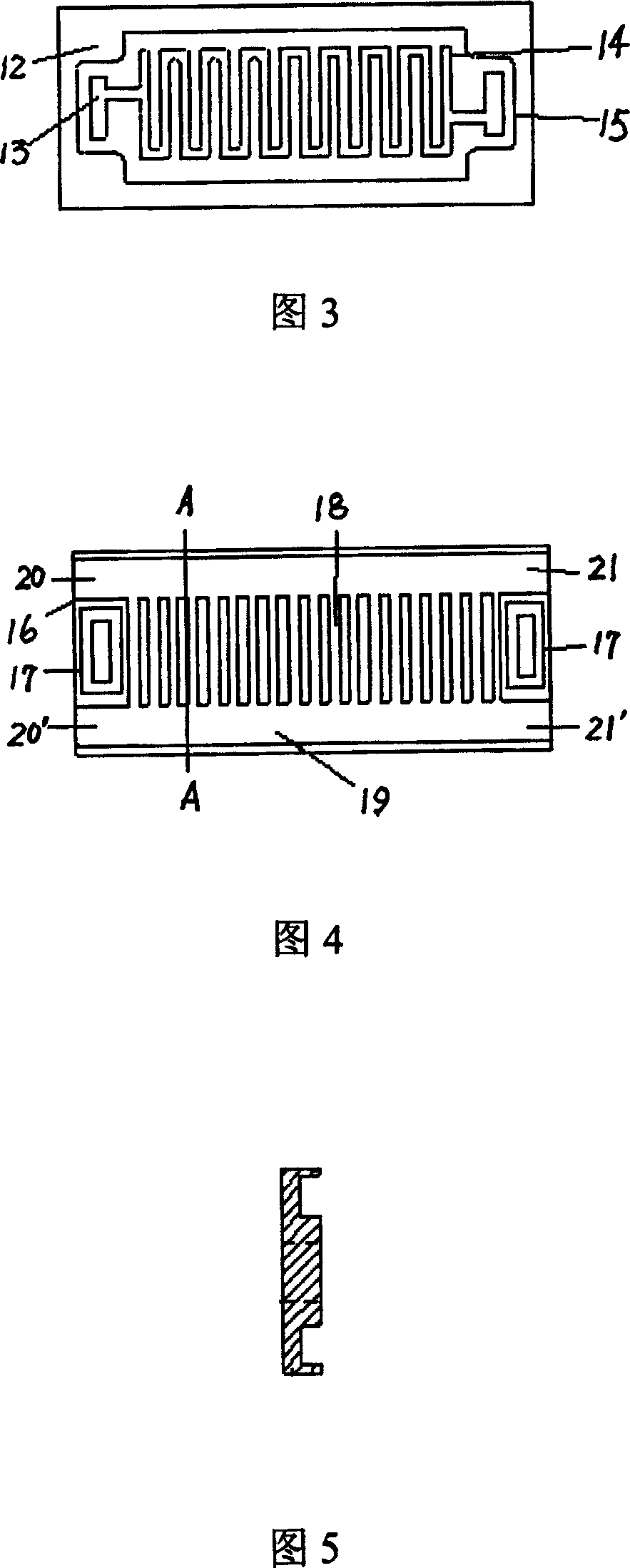

[0026] Attached Figure 2 shows a schematic diagram of battery stack assembly; 8 is the front and rear end plates of the battery stack, 9 is the current motherboard, 10 is the battery bipolar plate, and 11 is the three-in-one membrane electrode.

[0027] Accompanying drawing 3 has given the structure diagram of hydrogen gas side of bipolar plate 10; Among them, 12 bipolar plate hydrogen surface, 13 is hydrogen through-hole, 14 is hydrogen flow channel, 15 hydrogen sealing ring.

[0028] Accompanying drawing 4 has provided the air side structural diagram of bipolar plate 10; Wherein 16 is the air surface of bipolar plate, and sealing ring 17 is placed inside, and 18 is the reaction flow channel, and 19 is the cooling flow channel, and the air self-radiating flow channel entrance uses the same The wind pressure flows in at 20, 20' and flows out at the outlets 21, 21' of the flow channel to take away the heat generated by the battery. Among them, an air flow ratio adjustment devic...

Embodiment 3

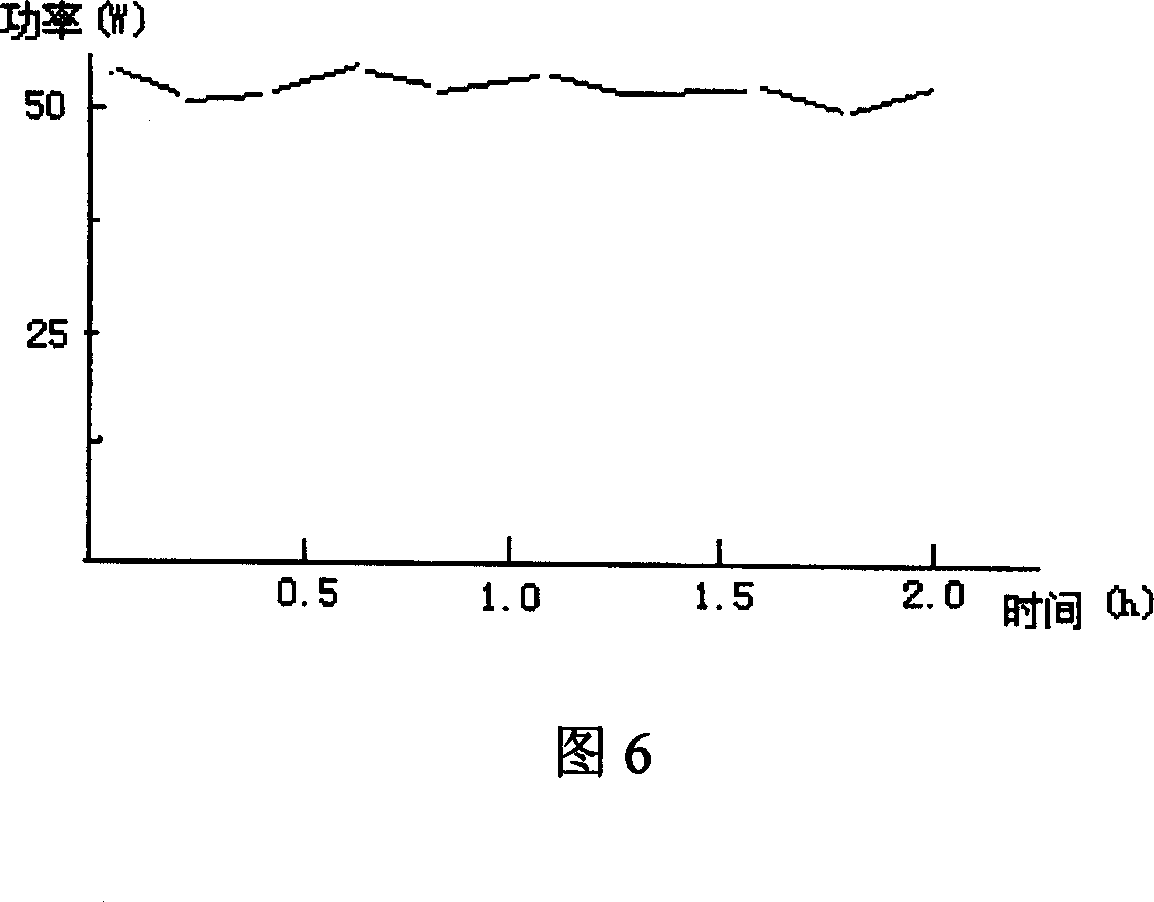

[0031] 50W integrated fuel cell system assembled with accompanying drawing 1. Among them, the bipolar plate adopts the method shown in attached drawing 3, attached drawing 4, and attached drawing 5. The area of the bipolar plate is 45mm×100mm, and the effective area of the three-in-one membrane is 25mm×80mm. 20 fuel cells are connected in series in the manner shown in Fig. 2 . The working temperature of the battery is 50°C, and when the output voltage of the battery is 12V, the current is about 4.5A, of which the power consumption of the fan is 2W (at this time, the ambient temperature is 30°C, and the power consumption of the fan varies with the ambient temperature), accounting for the entire battery stack 3.7% of output power. The power consumption of other control circuits and actuators is very low, about 0.2W. Accompanying drawing 6 has provided the battery output power (power supply voltage is 12V) with time variation relation curve; As can be seen from this figure,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com